Introduction

Navigating the complexities of catalog management can often feel like a daunting task for manufacturers, right? But here’s the good news: with the right catalog management system, this whole process can turn into a streamlined and efficient experience. In this article, we’ll explore ten essential features that not only boost operational efficiency but also elevate customer satisfaction.

But let’s pause for a moment. What happens when these features aren’t fully utilized? Are manufacturers missing out on significant opportunities to optimize their operations and truly connect with their customers? Let’s dive in and find out!

Equip360: Comprehensive B2B eCommerce Platform for Catalog Management

Have you ever felt overwhelmed by the catalog management system while managing product listings? Well, Equip360 is here to change that! This robust B2B eCommerce platform makes it super easy for producers to handle their products. With features like customizable product listings and advanced search capabilities, it’s designed to simplify your life.

Imagine having all your product details accurate and up-to-date, which is essential for keeping your clients happy and trusting you. Plus, Equip360 seamlessly integrates with your existing ERP systems, so you won’t have to worry about a complicated setup.

So, why not give it a try? Equip360 not only helps you manage your listings effectively through a robust catalog management system but also ensures that your clients get the best experience possible. After all, a satisfied customer is a loyal customer!

Real-Time Inventory Tracking: Essential for Efficient Catalog Management

Have you ever wondered how manufacturers keep track of their stock? Real-time inventory tracking is the answer! It allows manufacturers to keep a close eye on stock levels, making sure that what’s available in their catalogs is accurate. This not only helps prevent overselling but also enhances the customer experience by providing reliable, up-to-date information on product availability.

When inventory is monitored precisely, it leads to happier customers. Why? Because they can trust that the products they want are actually in stock, which means fewer order cancellations. By integrating real-time tracking with their catalog management system, businesses can quickly respond to changes in demand, ensuring they have just the right amount of inventory to meet customer needs.

Think about it: real-time tracking cuts down on errors and boosts efficiency. It automatically records stock changes, which helps minimize backorders and speeds up fulfillment. This builds trust and loyalty among customers. When clients can rely on accurate stock information, they feel more confident making purchases.

As more manufacturers adopt advanced tracking technologies, they’re set to enhance their operational efficiency and improve the overall customer experience. With expectations of a 1.6% decrease in inventories over the next year, the importance of real-time tracking becomes even clearer. But let’s not forget about the potential upfront costs of implementing this technology. It’s a crucial factor that many producers need to weigh in their decision-making process.

So, what do you think? Is it time for your business to consider real-time inventory tracking?

![]()

ERP Integration: Seamless Connectivity for Enhanced Catalog Management

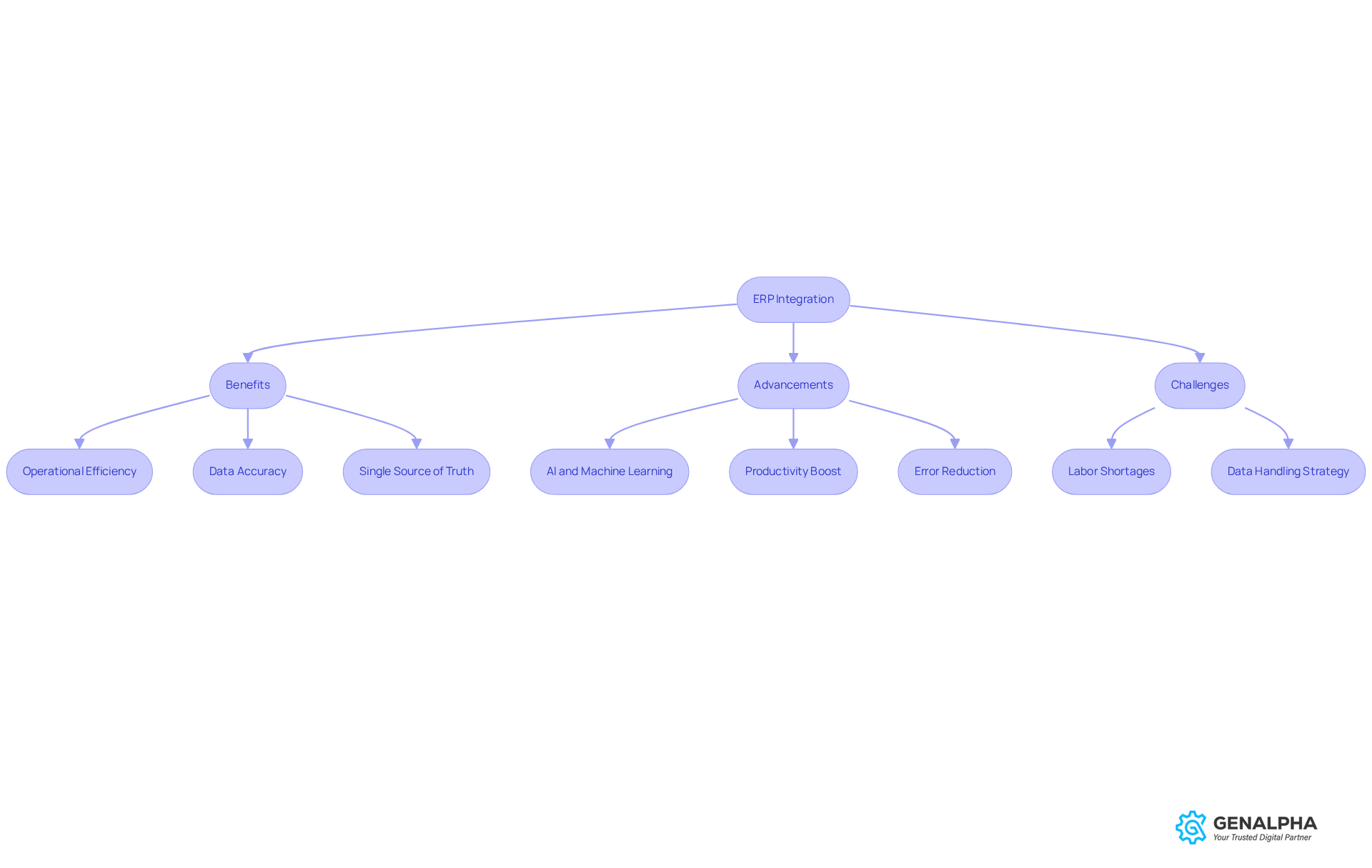

Smooth ERP integration is super important for keeping an eye on products for producers. Imagine connecting your catalog management system with ERP solutions - suddenly, you can sync up product data, pricing, and inventory levels across all platforms. This kind of connectivity not only boosts operational efficiency but also establishes a catalog management system that serves as a single source of truth for product info. That means fewer discrepancies and way better data accuracy.

Now, let’s talk about some cool advancements. Recent updates in ERP systems, especially with AI and machine learning, have really streamlined processes and improved decision-making. For example, producers using these technologies have seen a boost in productivity and a drop in manual errors. Take Boyce Precision Engineering, for instance. They managed to cut stock by 25% and achieve a 20% year-on-year growth just by syncing their product data with ERP systems. Pretty impressive, right? This shows how effective data synchronization can lead to better inventory oversight and happier customers.

But it’s not all smooth sailing. Producers are facing challenges like labor shortages and the need for a solid data handling strategy. This really highlights how urgent it is to embrace these integrated solutions. So, what do you think? Are you ready to take the plunge into smoother operations?

User-Friendly Interface: Simplifying Catalog Management for Manufacturers

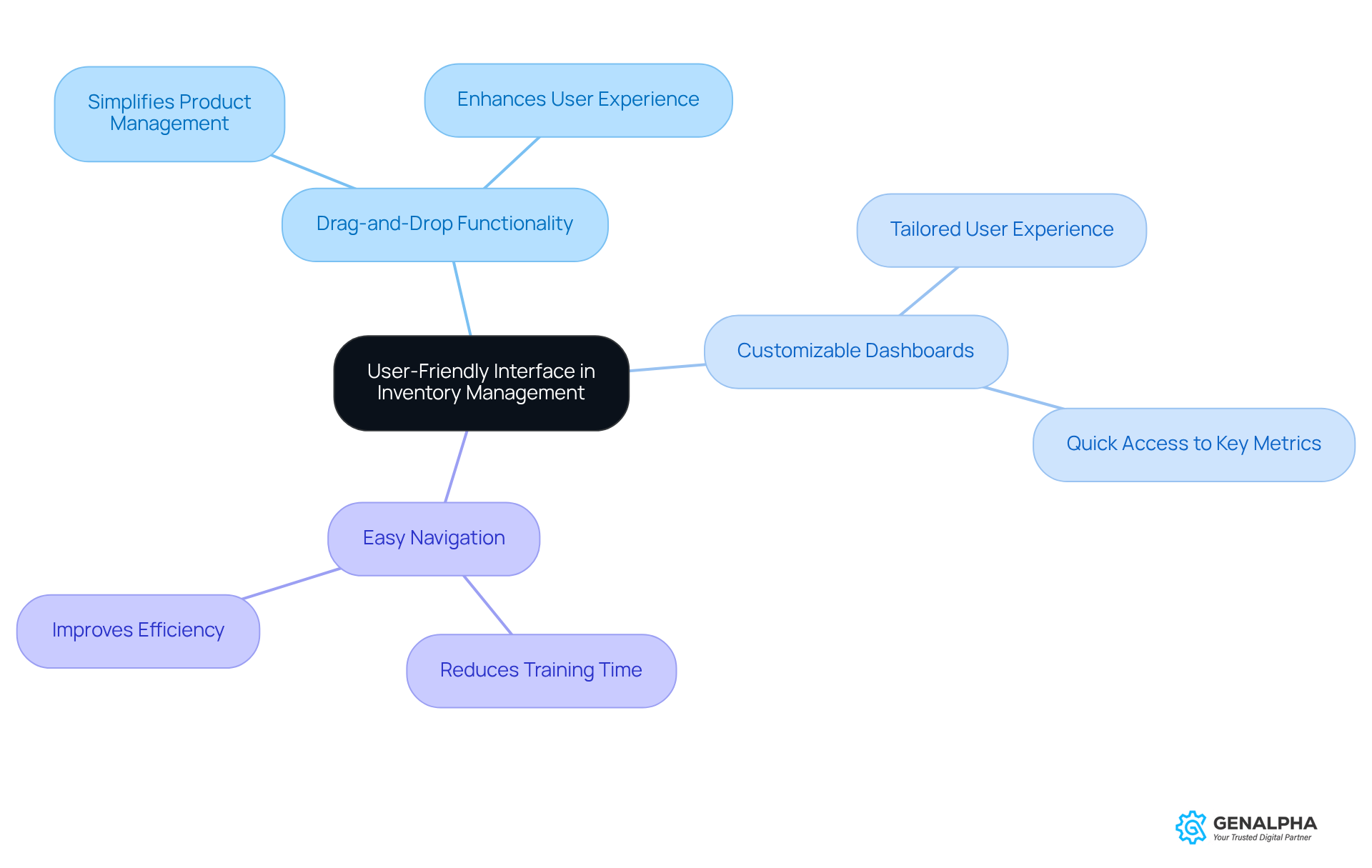

An intuitive interface is key for inventory management systems, right? It lets producers browse and manage their collections effortlessly. Think about features like drag-and-drop functionality, customizable dashboards, and easy navigation-these tools help users quickly find and update product information. This simplification not only cuts down on training time but also helps teams manage inventories more effectively.

For example, manufacturers using platforms with user-friendly interfaces, like KHUB, have seen a big drop in onboarding time. This means staff can focus on strategic tasks instead of wrestling with complicated systems. Plus, expert insights show that prioritizing user experience in inventory management can boost productivity and operational efficiency, leading to better business outcomes.

And with the system oversight sector projected to hit a whopping USD 2.34 billion by 2025, it’s clear that efficient inventory management solutions are more important than ever. So, how are you ensuring your team has the best tools at their disposal?

Advanced Analytics: Driving Data-Driven Decisions in Catalog Management

Have you ever wondered how some businesses seem to know exactly what their customers want? Well, sophisticated analytical tools integrated into inventory systems are making that possible! These tools help producers analyze client interactions and stock trends efficiently. By tapping into data-driven insights, businesses can identify their top-performing products, accurately forecast demand, and utilize their catalog management system to adjust offerings on the fly.

This proactive approach not only boosts inventory management but also supercharges marketing efforts by aligning them with what customers really prefer. For example, data analytics can help manufacturing companies cut down on unplanned downtime and maintenance costs, leading to smoother operations overall. And here’s a fun fact: organizations that embrace a data-first mindset are three times more likely to see improvements in decision-making. That really highlights how crucial analytics is for modern catalog management system practices!

As Kate Brown, a partner with Wipfli, puts it, "Advanced analytics and AI should now touch every facet of your value chain, from inventory forecasting and procurement to quality control and production." This holistic integration of analytics is key to maximizing the benefits of data-driven decision-making. So, why not consider how you can leverage these insights in your own business?

Digital Warranty Management: Enhancing Customer Satisfaction in Catalog Systems

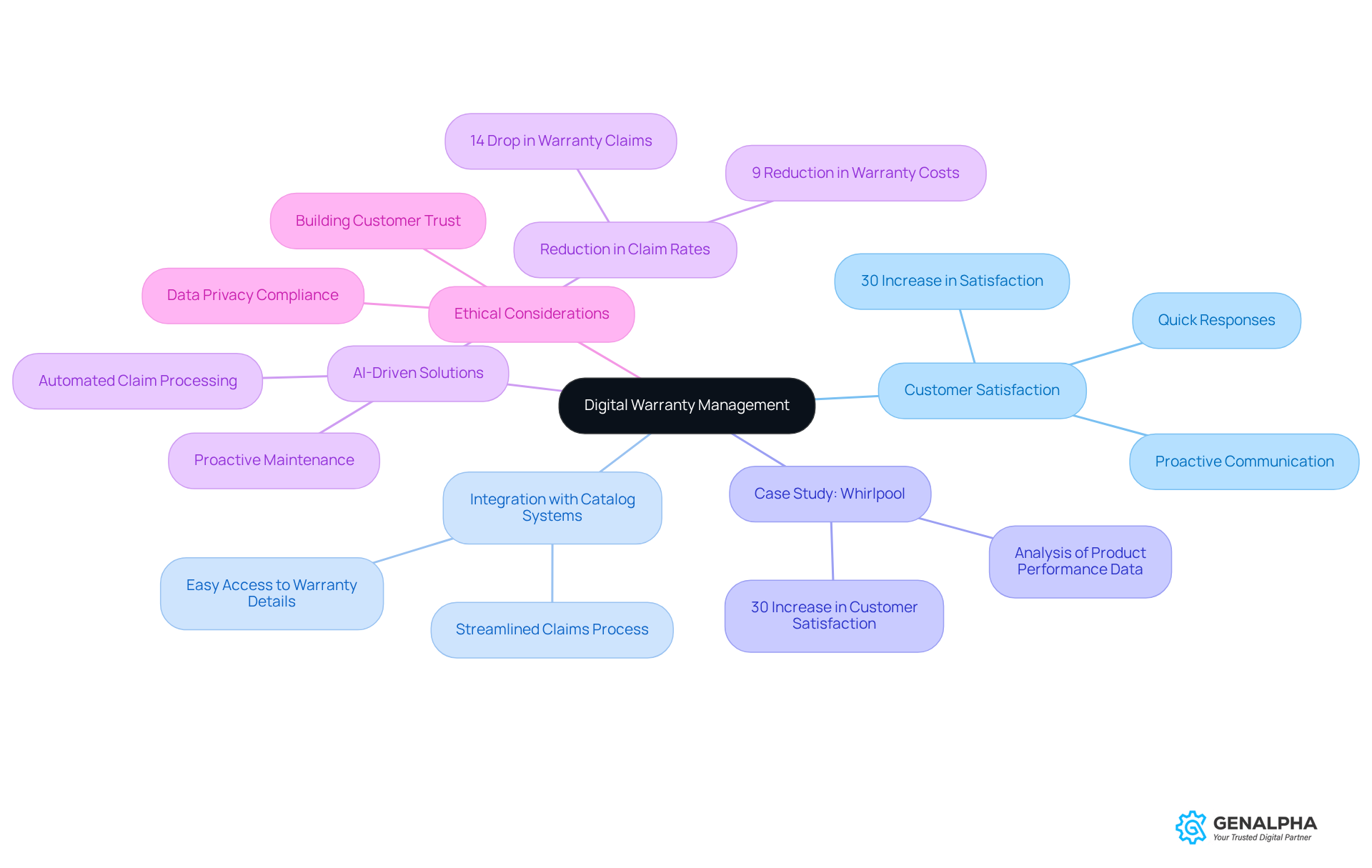

Have you ever thought about how digital warranty management systems can really change the game for manufacturers? By integrating these systems with a catalog management system, companies can make warranty claims a breeze and truly enhance user experiences. Imagine having straightforward access to warranty details and claim procedures right at your fingertips-this not only boosts customer satisfaction but also builds trust.

When warranty information is easily accessible alongside product specs through the catalog management system, buyers can really grasp their coverage and benefits. Take Whirlpool, for instance. They’ve successfully used warranty oversight systems to analyze product performance data, leading to a whopping 30% increase in customer satisfaction and fewer defects. Pretty impressive, right?

And here’s something to think about: the latest trends show that manufacturers using AI-driven warranty solutions are seeing a significant uptick in customer loyalty. These systems allow for proactive communication and quick resolutions, which is a win-win for everyone involved. In fact, top-tier companies that manage warranties well experience a 14% drop in warranty claim rates and a 9% reduction in warranty costs each year. That’s some serious savings!

As more producers jump on board with these technologies, having easy access to warranty information will be crucial for building customer confidence and satisfaction. But let’s not forget-ethical considerations in AI implementation are key to maintaining that trust. So, what do you think? Are you ready to explore how these innovations can benefit your business?

Mobile Accessibility: Managing Catalogs Anytime, Anywhere

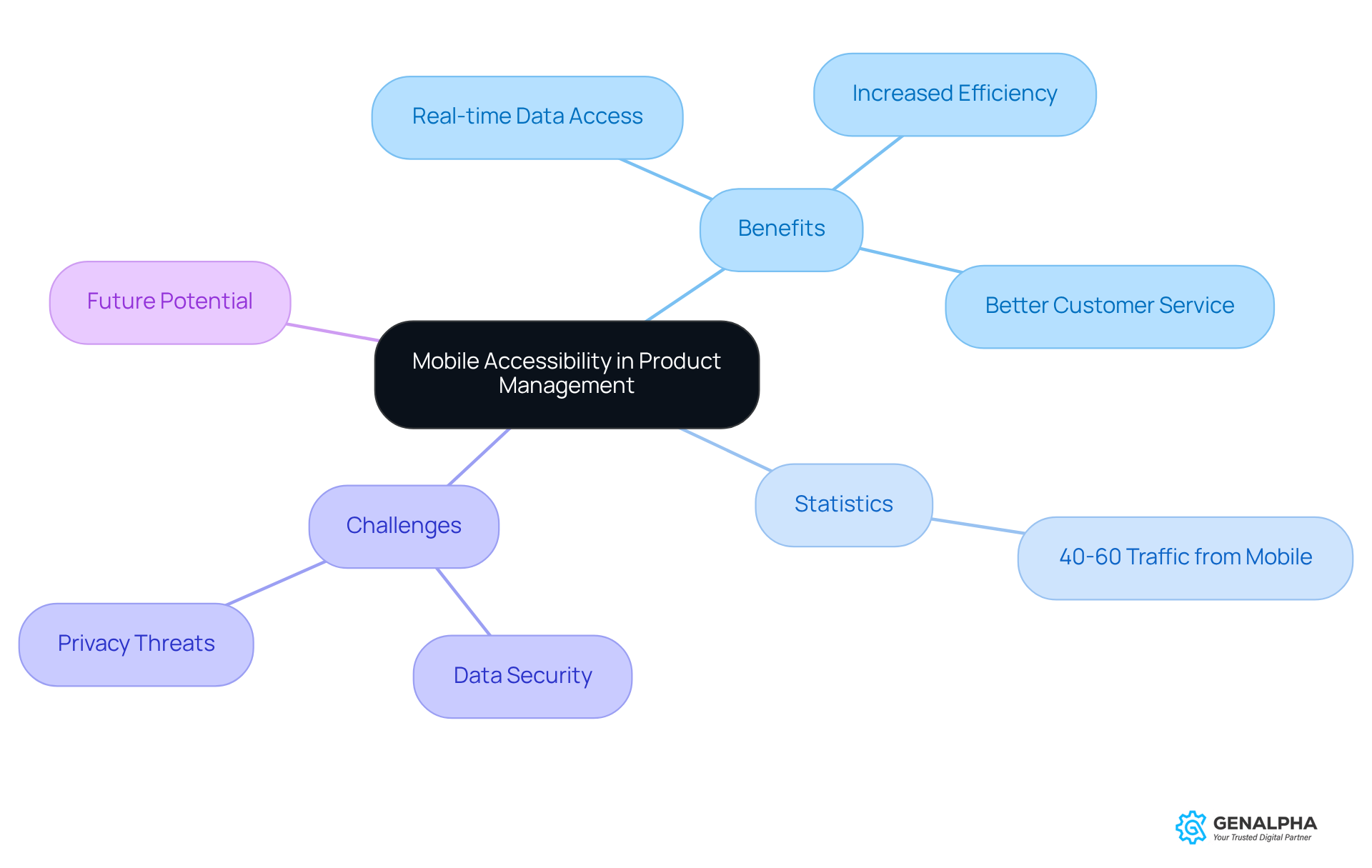

Have you ever found yourself needing to check your product listings while on the go? Mobile accessibility in product oversight systems makes that possible! Producers can manage their item listings from just about anywhere, anytime. This is a game-changer for sales teams and managers who need quick access to real-time data while they’re out and about.

Imagine using mobile-friendly inventory management tools that boost your efficiency and responsiveness. This means better service for your clients! For example, mobile apps allow for real-time inventory tracking and give instant access to crucial production data. This way, teams can make informed decisions in a snap. Did you know that research shows 40-60% of all course catalog traffic comes from mobile devices? That really highlights how essential mobile solutions have become.

This flexibility not only ramps up operational efficiency but also encourages a proactive approach to customer engagement. It ensures that the right materials are available when they’re needed. As more producers embrace mobile solutions, they’re seeing significant boosts in productivity and sales performance. Evelyn DuJack puts it perfectly: "The mobile revolution in manufacturing is just getting started." This really emphasizes the transformative potential of these technologies.

However, it’s important to remember that with great power comes great responsibility. Producers need to tackle challenges related to data security and privacy threats, which are crucial when implementing mobile inventory management solutions. So, what steps are you taking to ensure your mobile systems are secure?

Customizable Catalog Features: Tailoring Solutions for Market Needs

Have you ever thought about how customizable features in a catalog management system can really change the game for producers? Imagine being able to use a catalog management system to tweak product offerings to meet the unique needs of different markets. This means adjusting product descriptions, pricing, and availability within the catalog management system based on consumer segments or even their location.

By offering a tailored experience, producers can not only enhance client engagement but also see a boost in sales. It’s all about making the customer feel special and understood, right?

So, what’s stopping you from exploring these customizable options? Think about the potential to connect with your audience on a deeper level. Let’s dive into how these features can transform your approach and drive success!

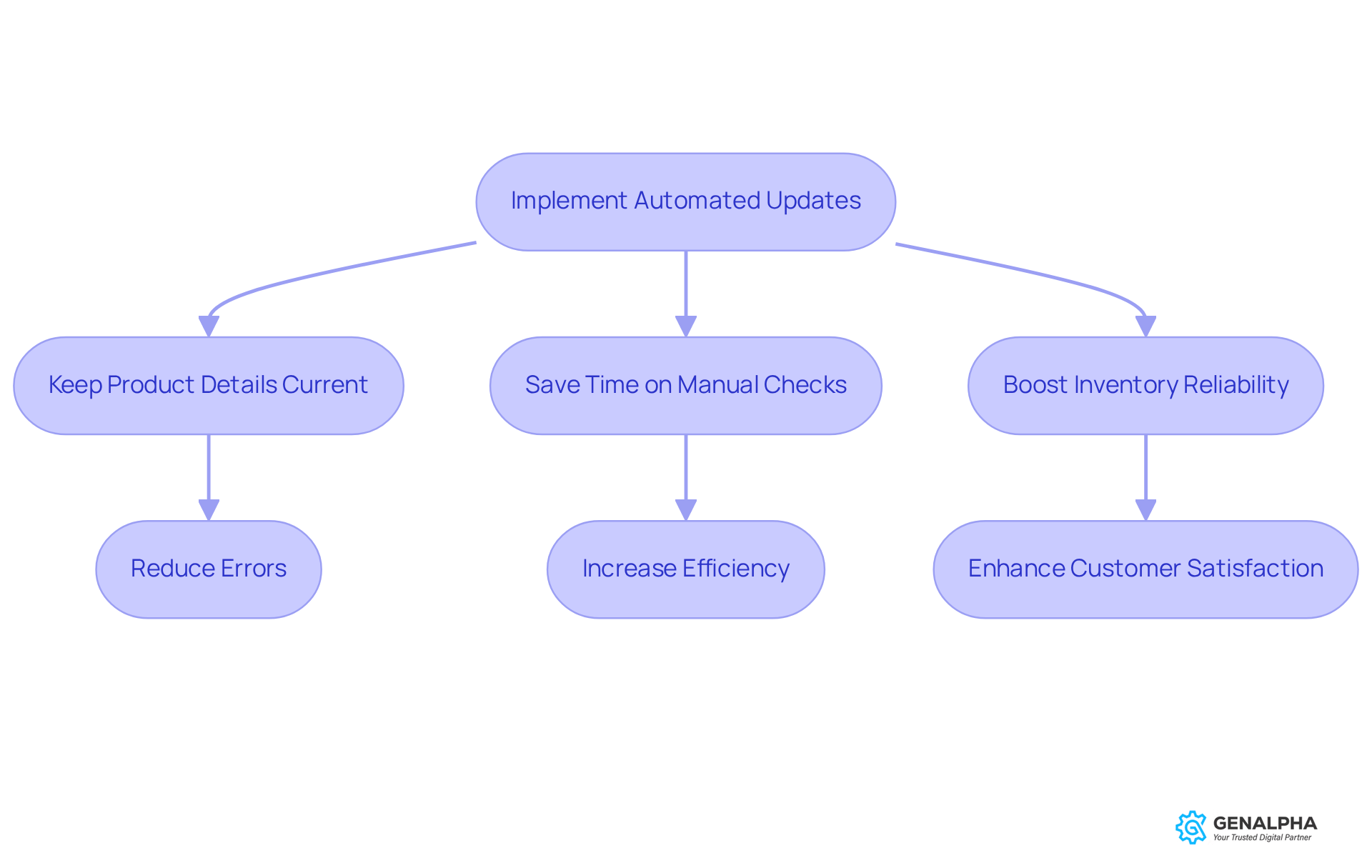

Automated Updates: Ensuring Accurate and Current Catalog Information

Have you ever felt frustrated when product information isn’t up-to-date? Automated updates in inventory management systems can really save the day! By keeping product details, pricing, and availability current, producers can significantly reduce the chances of mistakes that might leave buyers unhappy.

This isn’t just about avoiding errors; it’s also a huge time-saver. Imagine how much smoother everything runs when you don’t have to double-check every detail manually. Plus, it boosts the overall reliability of your inventory.

So, why not embrace automation? It’s a smart move that can lead to happier customers and a more efficient operation. What do you think? Ready to make the switch?

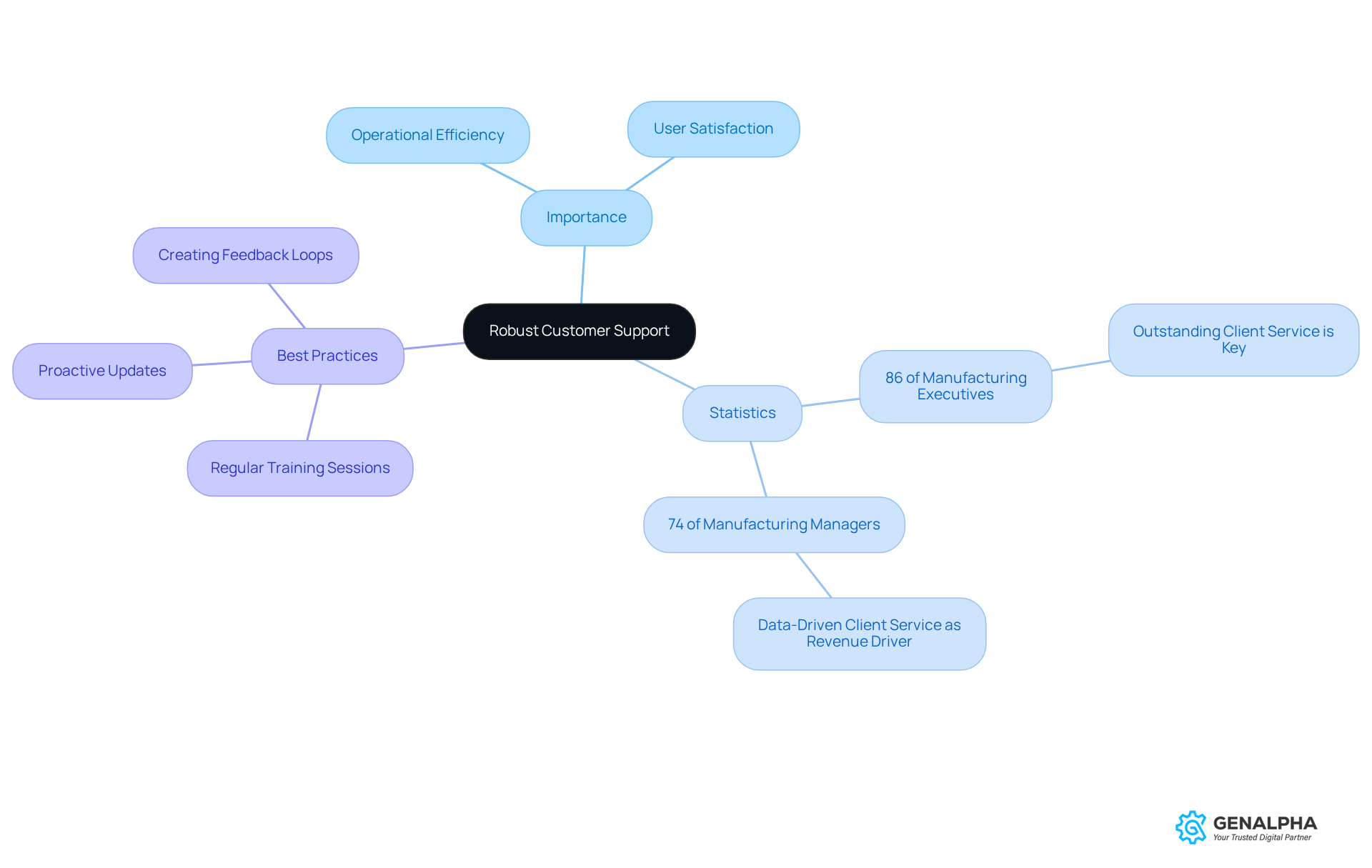

Robust Customer Support: Essential for Effective Catalog Management

Strong client support is truly the backbone of effective catalog management system operations, and it can make a world of difference for producers. When producers have access to knowledgeable support teams, they can tackle technical issues quickly, get personalized training, and learn the best ways to use the system. For instance, manufacturers that prioritize client support often report better operational efficiency and happier users. In fact, a whopping 86% of manufacturing executives believe that outstanding client service is key to standing out in the market. By leveraging solid support, companies can boost the value of their inventory solutions, making sure their teams are ready to navigate the complexities of stock management and product listings.

Now, let’s think about this: merging client support with a catalog management system doesn’t just simplify processes; it also fosters a culture of continuous improvement. A striking 74% of manufacturing managers believe that a data-driven client service approach will be their main revenue driver in the next decade. So, what are some best practices?

- Regular training sessions

- Proactive updates about system changes

- Creating feedback loops to tackle user concerns

Investing in service training can really help staff adopt a client-centric mindset, which aligns perfectly with these practices. This proactive approach not only enhances the overall user experience but also allows manufacturers to tweak their product offerings based on market needs. Ultimately, strong customer support turns catalog management system from just another operational tool into a strategic asset that fuels growth and boosts customer satisfaction.

Conclusion

Equip360's catalog management system is truly a game-changer for manufacturers. It offers a suite of essential features that not only streamline product management but also enhance customer satisfaction. Imagine having tools like real-time inventory tracking, seamless ERP integration, and user-friendly interfaces at your fingertips! These tools help manufacturers optimize their operations and provide a superior experience for their clients. Plus, with advanced analytics and customizable options, businesses can make informed decisions and tailor their offerings to meet market demands.

Throughout this article, we've uncovered key insights into how each feature contributes to a more efficient catalog management process. For example, real-time inventory tracking ensures accurate stock levels, while ERP integration fosters data consistency across platforms. User-friendly interfaces simplify navigation, and advanced analytics drive data-driven strategies. Additionally, mobile accessibility and automated updates keep manufacturers agile and responsive. And let’s not forget about robust customer support, which enhances overall satisfaction and operational effectiveness.

As manufacturers continue to adapt to evolving market conditions, embracing these essential features will be crucial for success. The integration of innovative technologies not only improves operational efficiency but also strengthens customer relationships. By prioritizing these capabilities, manufacturers can stay ahead of the competition and create a more reliable and engaging catalog management experience. So, why not take a moment to evaluate your current systems? Consider how these advancements can be implemented to drive growth and enhance customer loyalty. Now's the time to make a move!

Frequently Asked Questions

What is Equip360?

Equip360 is a comprehensive B2B eCommerce platform designed for efficient catalog management, making it easier for producers to handle product listings with features like customizable product listings and advanced search capabilities.

How does Equip360 improve catalog management?

Equip360 simplifies catalog management by ensuring that product details are accurate and up-to-date, which helps maintain customer trust and satisfaction. It also integrates seamlessly with existing ERP systems, avoiding complicated setups.

What is the significance of real-time inventory tracking?

Real-time inventory tracking allows manufacturers to monitor stock levels accurately, preventing overselling and enhancing customer experience by providing reliable information on product availability.

How does real-time inventory tracking benefit customers?

It leads to happier customers by ensuring that the products they want are actually in stock, reducing order cancellations, and building trust through accurate stock information.

What are the operational benefits of integrating real-time tracking with catalog management?

Integrating real-time tracking minimizes errors, boosts efficiency, records stock changes automatically, reduces backorders, and speeds up fulfillment, contributing to customer loyalty.

What challenges do producers face when implementing real-time inventory tracking?

Producers may encounter upfront costs associated with implementing tracking technology, as well as challenges like labor shortages and the need for a solid data handling strategy.

Why is ERP integration important for catalog management?

Smooth ERP integration allows producers to sync product data, pricing, and inventory levels across platforms, enhancing operational efficiency and ensuring better data accuracy.

What advancements have improved ERP systems recently?

Recent updates in ERP systems, particularly involving AI and machine learning, have streamlined processes, improved decision-making, and reduced manual errors, leading to increased productivity.

Can you provide an example of successful ERP integration?

Boyce Precision Engineering successfully cut stock by 25% and achieved a 20% year-on-year growth by syncing their product data with ERP systems, showcasing the benefits of effective data synchronization.

What factors should producers consider when adopting integrated solutions?

Producers need to weigh the potential upfront costs of implementing integrated solutions against the benefits of improved operational efficiency and customer satisfaction.