Introduction

The manufacturing landscape is really changing fast, thanks to the quick rise of digital technologies that are set to redefine how we think about efficiency and productivity. As companies work hard to keep up in this digital age, it’s super important to grasp the transformative examples of digital innovation.

In this article, we’ll explore ten fascinating case studies that show how top manufacturers are using digital transformation to boost their operations, streamline supply chains, and enhance customer experiences.

But with so many exciting advancements on the horizon, one big question lingers: which strategies will truly lead to success in the manufacturing sector by 2025 and beyond?

GenAlpha Technologies: Revolutionizing Manufacturing with Digital Solutions

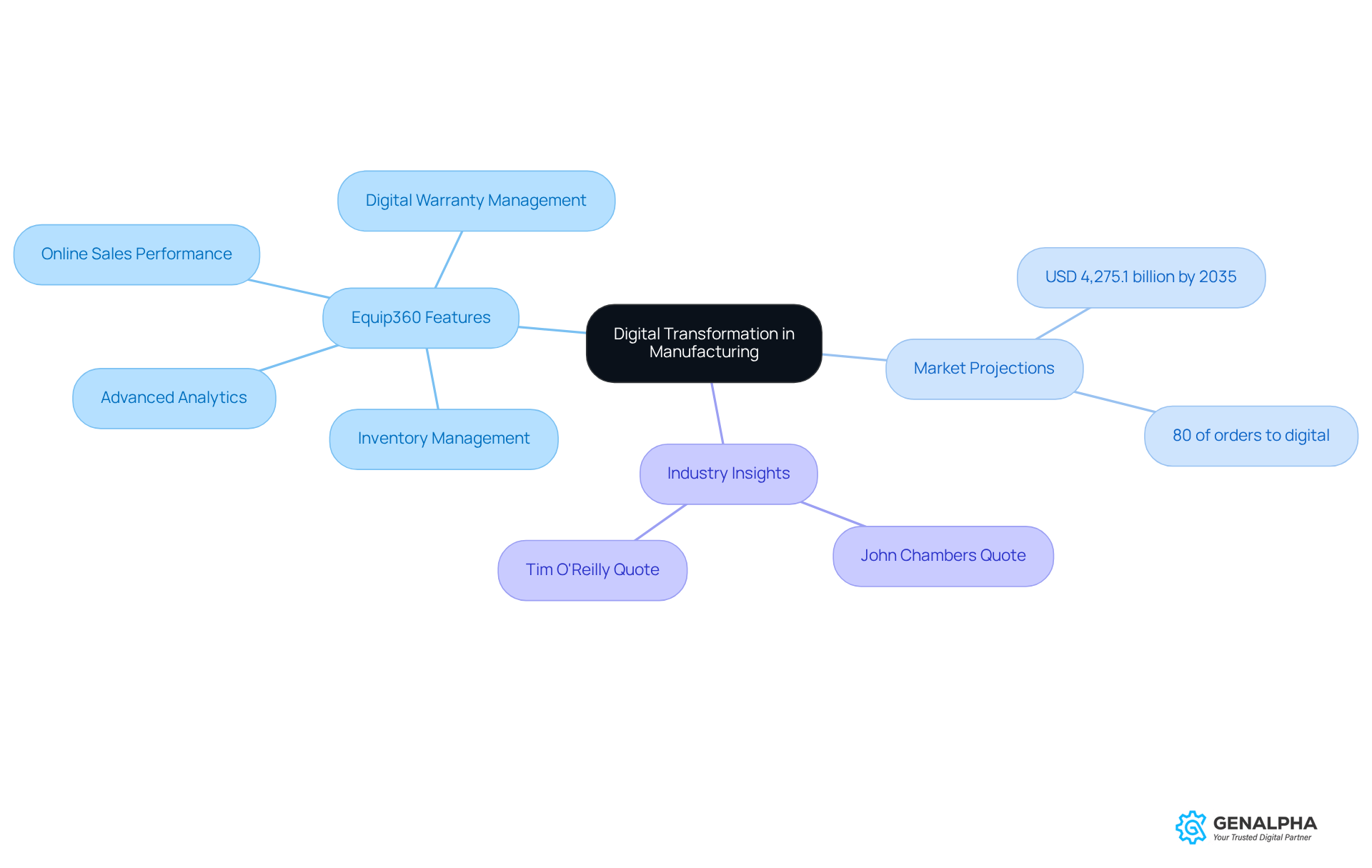

GenAlpha Technologies is really shaking things up in the production industry with their innovative digital transformation examples in manufacturing. They understand the unique challenges that equipment manufacturers and distributors face, and they’ve got just the thing to help: Equip360. This powerful B2B eCommerce platform is all about optimizing inventory management and boosting online sales performance. With features like digital warranty management and advanced analytics tools, Equip360 helps businesses streamline their operations and keep their clients happy. It’s not just about growth; it’s about thriving in a competitive marketplace.

Did you know that the digital transformation examples in manufacturing indicate that the market is expected to hit a whopping USD 4,275.1 billion by 2035? That’s a huge shift, especially with 80% of parts orders moving to digital channels within just a year of implementing eCommerce solutions, which are prime digital transformation examples in manufacturing. Equip360 is right at the heart of this change, seamlessly integrating with existing ERP systems to give real-time access to customer-specific pricing, inventory, and order status.

Industry leaders are stressing the need for adaptability in this digital age. As John Chambers puts it, businesses need to embrace change to survive. Tim O'Reilly also points out that every organization must transform to stay relevant. Equip360 not only meets these demands but also fosters a culture of innovation and teamwork. This way, producers can effectively respond to shifting customer expectations and market dynamics.

So, are you ready to embrace the digital transformation wave? Let’s chat about how Equip360 can help your business stay ahead!

Siemens: Leveraging Digital Twins for Enhanced Manufacturing Efficiency

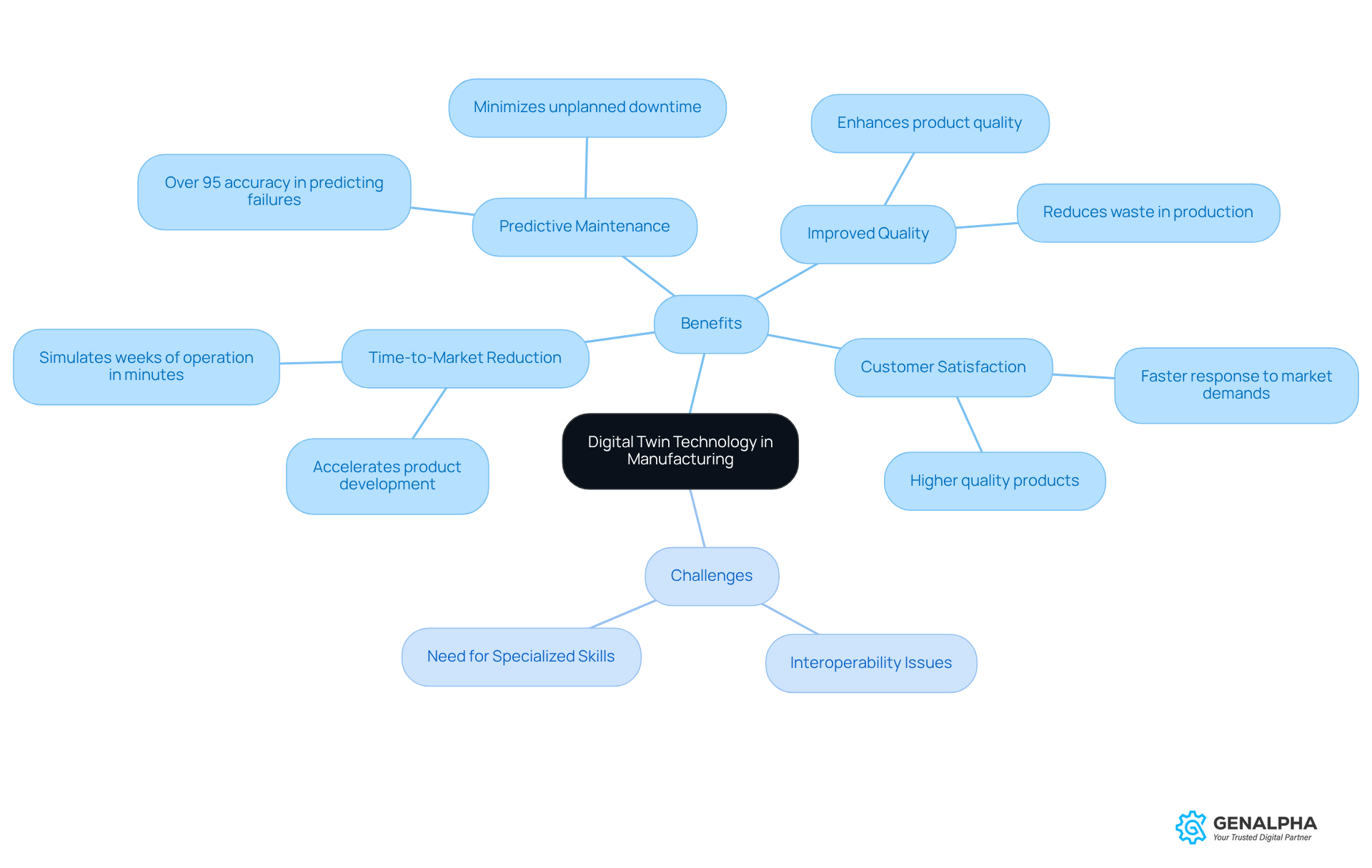

Siemens is really making waves in digital twin technology! They’re creating virtual replicas of physical assets that let producers simulate and optimize their processes. Imagine being able to test and refine workflows in a risk-free virtual environment—sounds great, right? This innovative approach can cut time-to-market by up to 50%, according to industry reports.

By tapping into real-time data, Siemens helps manufacturers predict equipment failures with over 95% accuracy. This means they can optimize production schedules and boost overall operational efficiency. The outcome? Not only is product quality improved, but customer satisfaction also gets a nice boost. Businesses can respond more quickly to market demands and cut down on waste.

Take GE Aviation, for example. They use digital twins to monitor engine performance in real time, which leads to better fuel efficiency and lower emissions. It’s clear that digital twins are significant digital transformation examples in manufacturing that play a crucial role in enhancing production efficiency and competitiveness as we look toward 2025.

But it’s not all smooth sailing. Producers face challenges when implementing digital twin technology, like interoperability issues and the need for specialized skills. As Siemens points out, the digital twin not only saves costs and avoids planning errors but also increases planning reliability and speeds up commissioning.

So, what do you think? Could your business benefit from embracing this technology?

GE Digital: Utilizing IoT for Predictive Maintenance and Operational Optimization

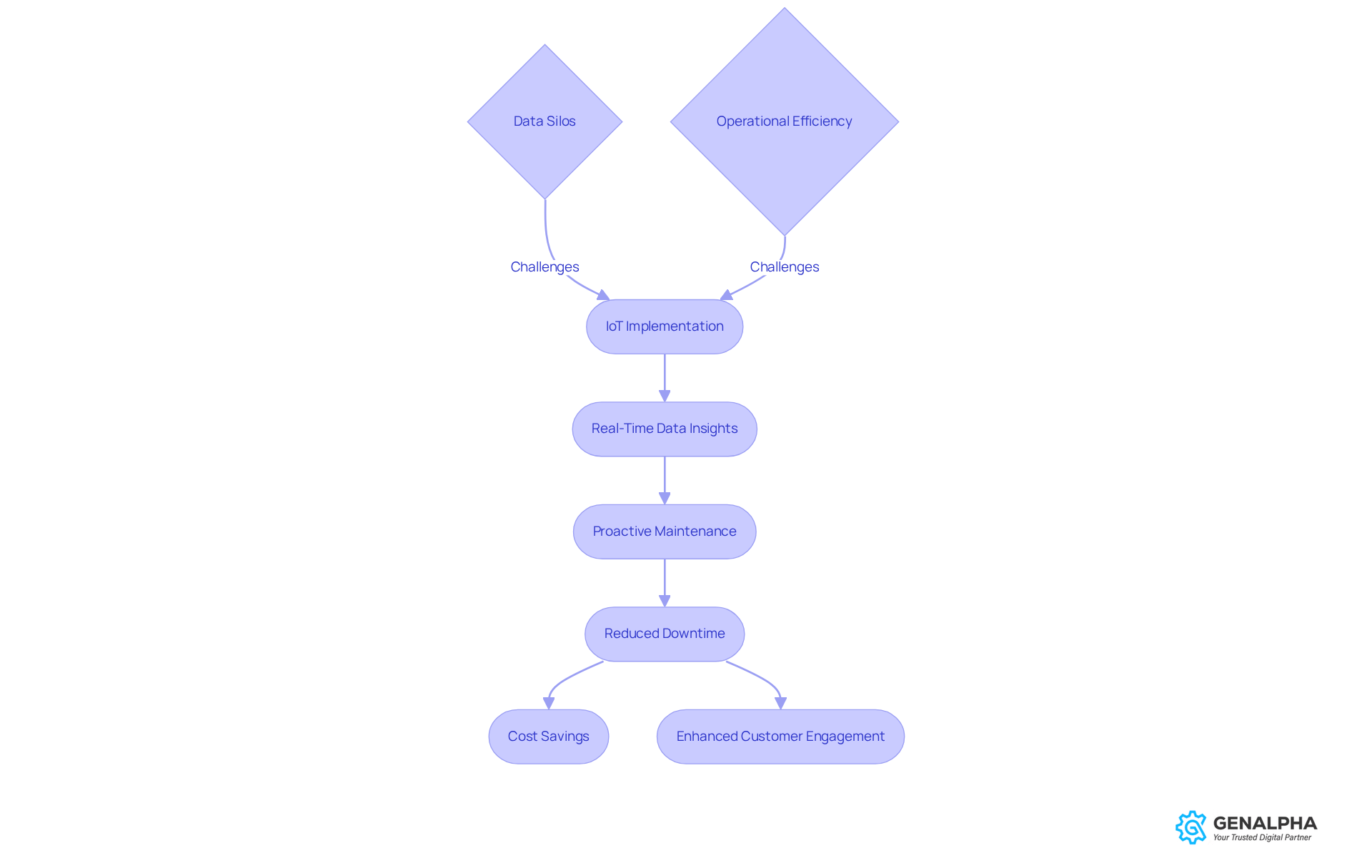

Have you ever wondered how digital transformation examples in manufacturing, such as the Internet of Things (IoT), could change the game? Well, GE Digital is doing just that by revolutionizing predictive maintenance. By using IoT sensors and advanced analytics, they’re giving manufacturers real-time insights into equipment health. This means they can tackle maintenance proactively, catching potential failures before they happen.

Imagine cutting your equipment downtime by up to 30%! That’s what predictive maintenance can do, leading to significant cost savings. For instance, GE has invested a whopping $1 billion in sensor innovation and cloud connectivity through its Predix platform. This investment has not only improved decision-making but also optimized operations across various industrial sectors.

Of course, it hasn’t all been smooth sailing. GE has faced challenges like data silos and the constant need for operational efficiency. But they’re tackling these issues head-on with strategic tech investments. As a result, manufacturers are seeing happier clients thanks to more reliable product delivery and fewer service interruptions.

A GE representative shared, "Real-time data insights allowed us to strengthen relationships with clients, providing them with valuable information to optimize their operations." This integration of predictive maintenance, along with AI and machine learning capabilities in the Predix platform, is one of the digital transformation examples in manufacturing that helps companies not just survive but thrive in a competitive landscape.

So, if you’re in manufacturing, why not think about how IoT solutions could boost your operational efficiency and enhance customer engagement? It’s time to explore the possibilities!

Rockwell Automation: Streamlining Processes with Smart Manufacturing Technologies

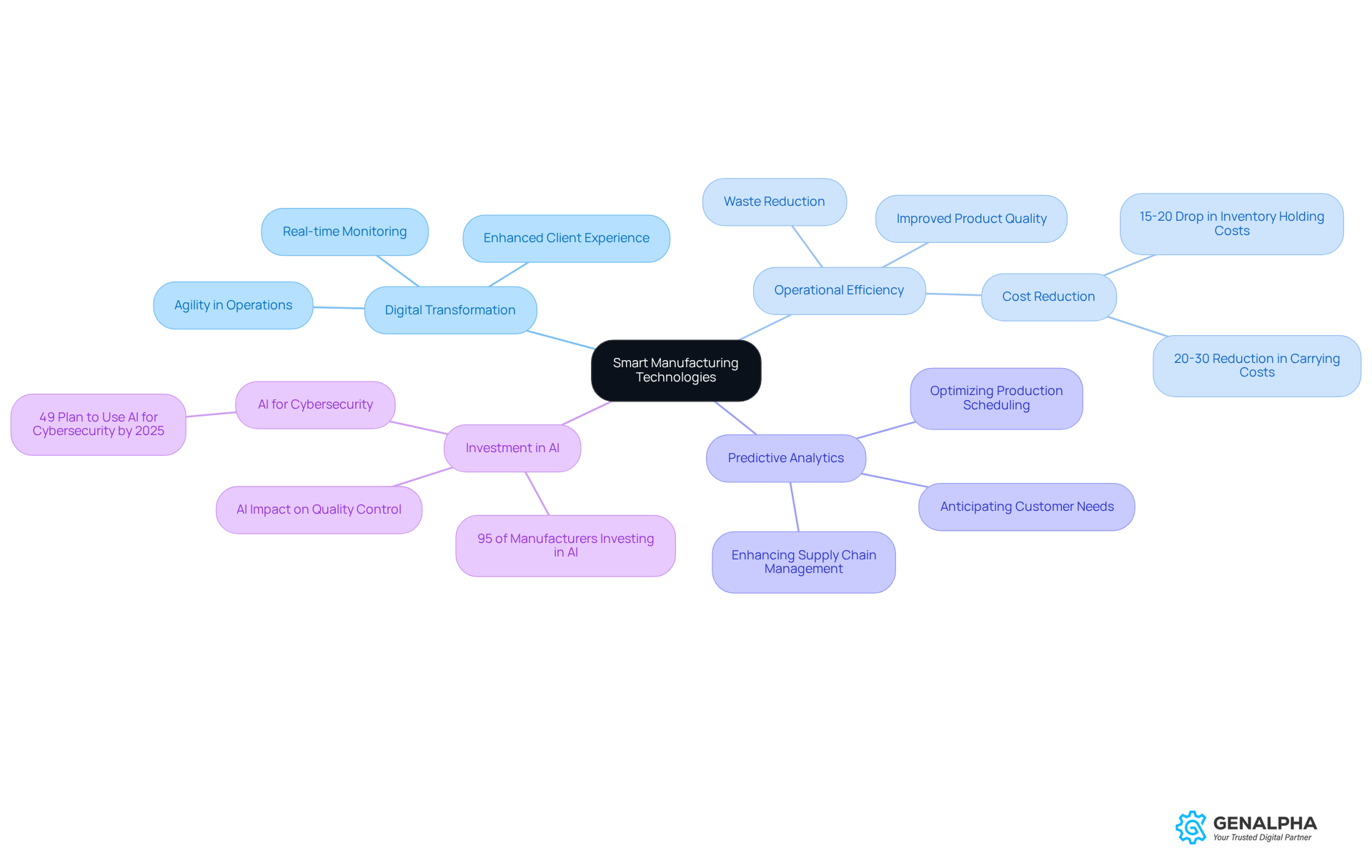

Rockwell Automation is really leading the way in smart manufacturing with notable digital transformation examples in manufacturing, utilizing cutting-edge tech to enhance production processes better than ever. Their solutions blend data analytics, machine learning, and automation, which are key digital transformation examples in manufacturing that significantly boost operational efficiency. Imagine being able to monitor and control everything in real-time! That’s what Rockwell offers, helping producers cut down on waste, improve product quality, and quickly adapt to what the market needs.

This kind of agility not only makes operations smoother but also improves the client experience with faster and more reliable service. As more producers start using predictive analytics, they can get ahead of customer needs and make the most of their resources. This could lead to a 15-20% drop in inventory holding costs—pretty crucial for keeping production costs in check, right?

And here’s something to think about: 95% of manufacturers are expected to invest in AI and machine learning technologies in the next five years. That really highlights how urgent these innovations are! Blake Moret, the CEO of Rockwell Automation, points out that in the next year, AI and machine learning will have a huge impact on quality control and process optimization. This just goes to show how essential digital transformation examples in manufacturing are for boosting efficiency and staying competitive in the industry.

So, what do you think? Are you ready to embrace these changes and see how they can transform your operations?

Honeywell: Enhancing Safety and Efficiency with Advanced Automation Solutions

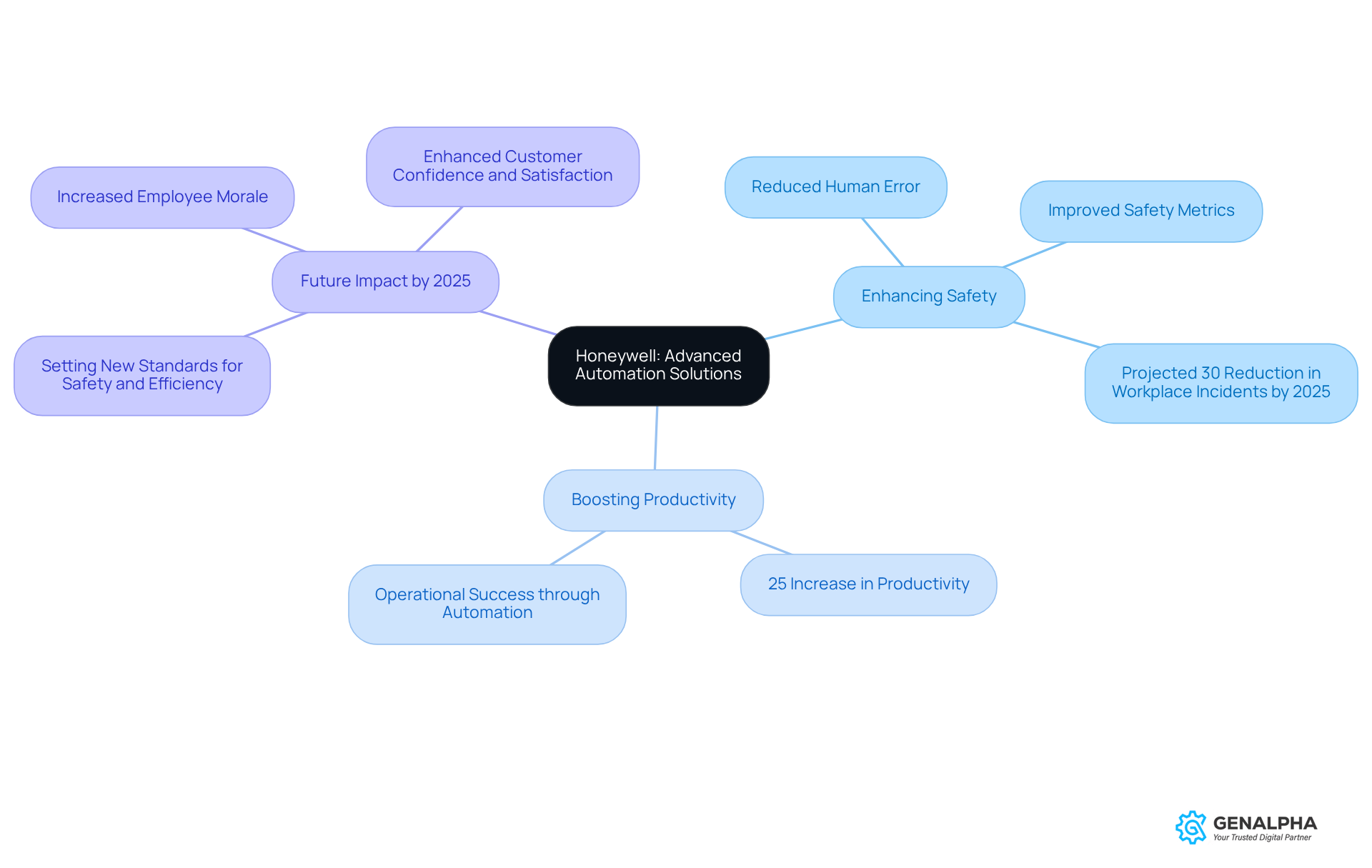

Honeywell's advanced automation solutions are really shaking things up in production! They’re not just about tech; they’re about making workplaces safer and more efficient. Think about it: with robotics and process automation, the chances of human error drop significantly, and workflows become a breeze. Industry experts even say that by 2025, integrating robotics could cut workplace incidents by up to 30%. That’s a game-changer for safety in modern manufacturing.

Take, for example, a well-known automotive company that decided to implement Honeywell's robotics solutions, which are among the digital transformation examples in manufacturing. They saw a whopping 25% boost in productivity while also improving their safety metrics. Pretty impressive, right? Bill Gates once said, 'Automation applied to an efficient operation will enhance the effectiveness.' This really highlights how crucial these advancements are for operational success.

So, what does this mean for producers? By adopting these solutions, they can ramp up productivity while ensuring a safer work environment. This not only boosts employee morale but also builds customer confidence and satisfaction. As we look ahead to 2025, the impact of robotics on production productivity is set to be huge. Companies that embrace these technologies will be the ones setting new standards for safety and efficiency.

If you’re in production, now’s the time to think about investing in advanced automation solutions that align with your operational goals. Why wait? The future is bright, and it’s all about working smarter and safer!

Bosch: Driving Innovation with Big Data Analytics in Manufacturing

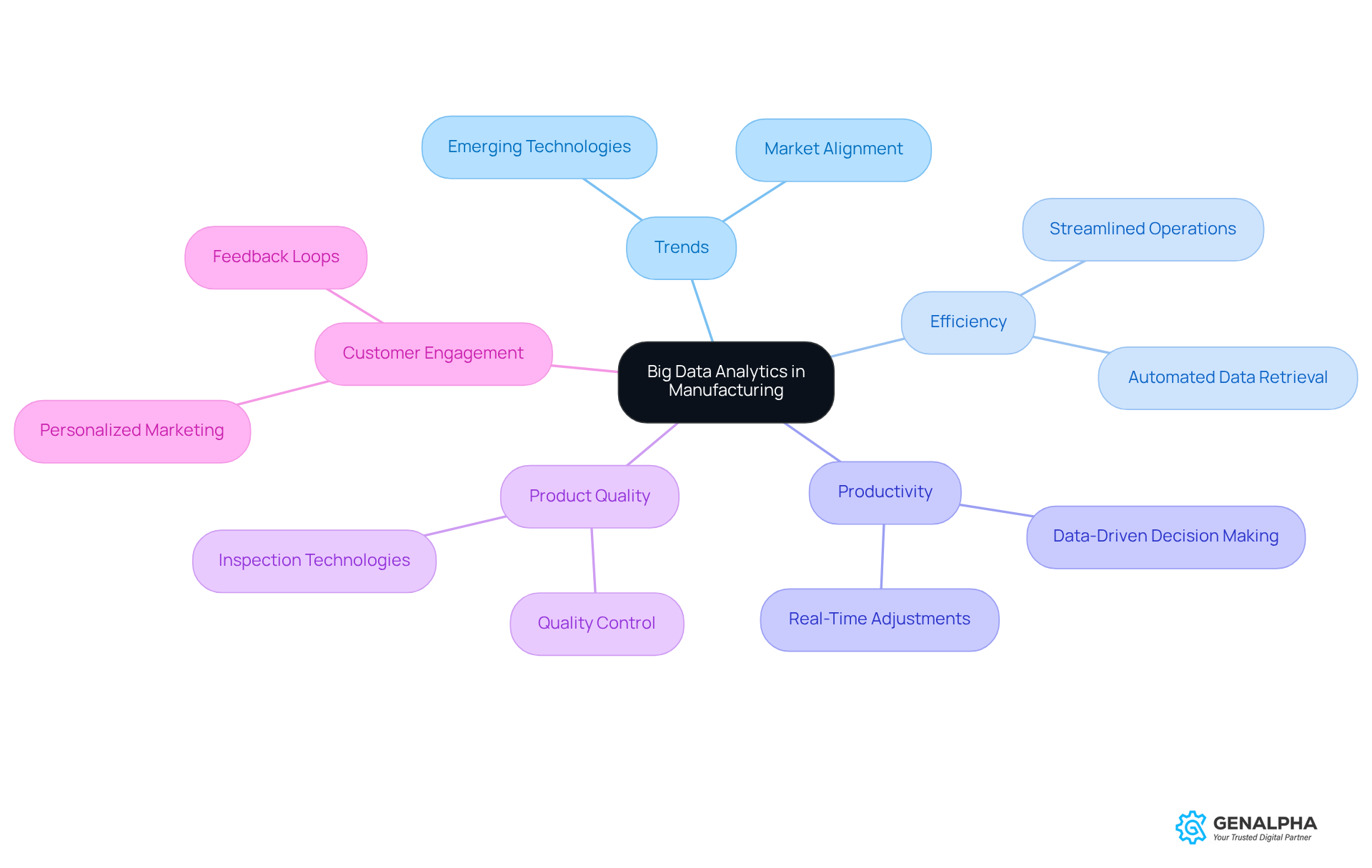

Have you ever wondered how big data can change the game in manufacturing? Well, Bosch is leading the charge in using big data analytics to spark innovation in this sector. By diving deep into the vast amounts of data generated from production processes, Bosch is able to spot important trends and pinpoint inefficiencies that might be holding back performance.

This data-driven approach isn’t just about crunching numbers; it’s about making smart choices that can really ramp up productivity and enhance product quality. Imagine being able to align what you produce with what the market actually wants—sounds great, right? That’s exactly what Bosch is doing, and it’s making a real difference in customer engagement.

So, how can producers like you tap into the power of big data? By embracing this kind of decision-making, you can not only improve your operations but also stay competitive in a rapidly changing marketplace. It’s all about leveraging insights to drive success. What steps will you take to harness the potential of big data in your own operations?

ABB: Transforming Manufacturing with Robotics and Automation

Have you ever thought about how robots are changing the way we make things? ABB is at the forefront of this revolution, bringing some seriously cool robotics and automation solutions to the manufacturing world. By weaving advanced robotics into production lines, ABB isn’t just boosting efficiency; they’re also cutting down on labor costs and upping product quality.

Imagine a factory where producers can quickly adapt to changing market demands. That’s exactly what ABB’s automation systems do! They help businesses respond to customer needs faster and more effectively, which means happier clients all around.

So, if you’re curious about how technology can transform industries, ABB is definitely a name to watch. Why not explore how these innovations could benefit your own operations?

Caterpillar: Enhancing Supply Chain Management with Digital Technologies

Caterpillar is really leading the charge by providing digital transformation examples in manufacturing! They’re implementing digital transformation examples in manufacturing, such as advanced analytics and IoT solutions, to supercharge their supply chain management. Imagine having real-time visibility into operations—that’s exactly what these technologies provide. It’s a game changer for effective inventory management and nailing down accurate demand forecasting.

This proactive approach is among the digital transformation examples in manufacturing that not only streamline processes but also boost customer satisfaction. Timely deliveries and high product quality? Yes, please! For example, digital transformation examples in manufacturing, such as IoT-enabled tracking, have been shown to cut waste by 20%, and predictive analytics can slash downtime by 30%. Those are some serious benefits of implementing digital transformation examples in manufacturing.

As Caterpillar keeps pushing the envelope, their commitment to leveraging technology really sets them apart as a leader in optimizing supply chain efficiency and responsiveness. So, what do you think? Are you ready to embrace the digital wave in your own operations? Let's dive into this exciting journey together!

Mitsubishi Electric: Optimizing Manufacturing with AI and Machine Learning

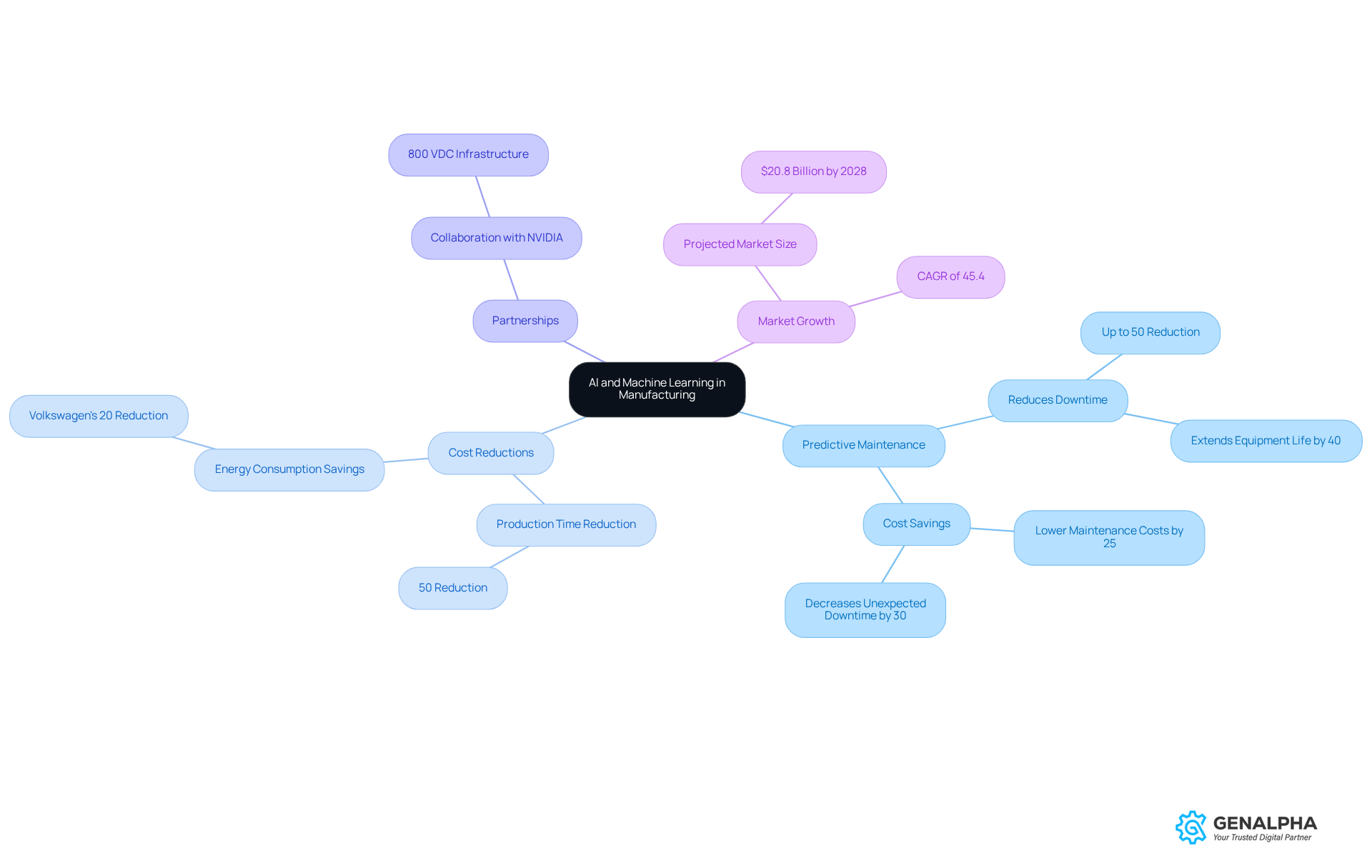

Mitsubishi Electric is really stepping up when it comes to blending AI and machine learning into manufacturing. This isn’t just about keeping up; it’s about boosting production efficiency and product quality in a big way. Imagine being able to predict when maintenance is needed—this can cut unexpected downtime by up to 50% and slash maintenance costs by as much as 25%! How cool is that? This proactive approach not only makes operations smoother but also helps manufacturers maintain high standards of reliability and quality.

For example, AI-powered predictive maintenance can extend equipment life by up to 40%. That means manufacturers can use their resources more effectively. Plus, Mitsubishi Electric is all about innovation, teaming up with NVIDIA to create 800 VDC infrastructure that meets the needs of today’s AI applications in factories. This partnership shows just how AI can transform production, leading to happier customers and better operations.

And here’s something to think about: the AI in manufacturing market is expected to grow to a whopping $20.8 billion by 2028! That really highlights how important these advancements are. So, what do you think? Are you ready to embrace the future of manufacturing?

Parker Hannifin: Driving Growth through Digital Transformation Strategies

Parker Hannifin is all about growth, and they’re implementing some impressive digital transformation examples in manufacturing to achieve it. They’re really leaning into IoT and data analytics, which are game-changers for boosting operational efficiency. Imagine being able to streamline processes and speed up product development—sounds great, right? By tapping into real-time data, Parker not only fine-tunes its operations but also builds stronger relationships with clients by offering tailored solutions that meet their specific needs. This approach has proven effective in ramping up customer satisfaction and loyalty, helping Parker stand out in a competitive production landscape.

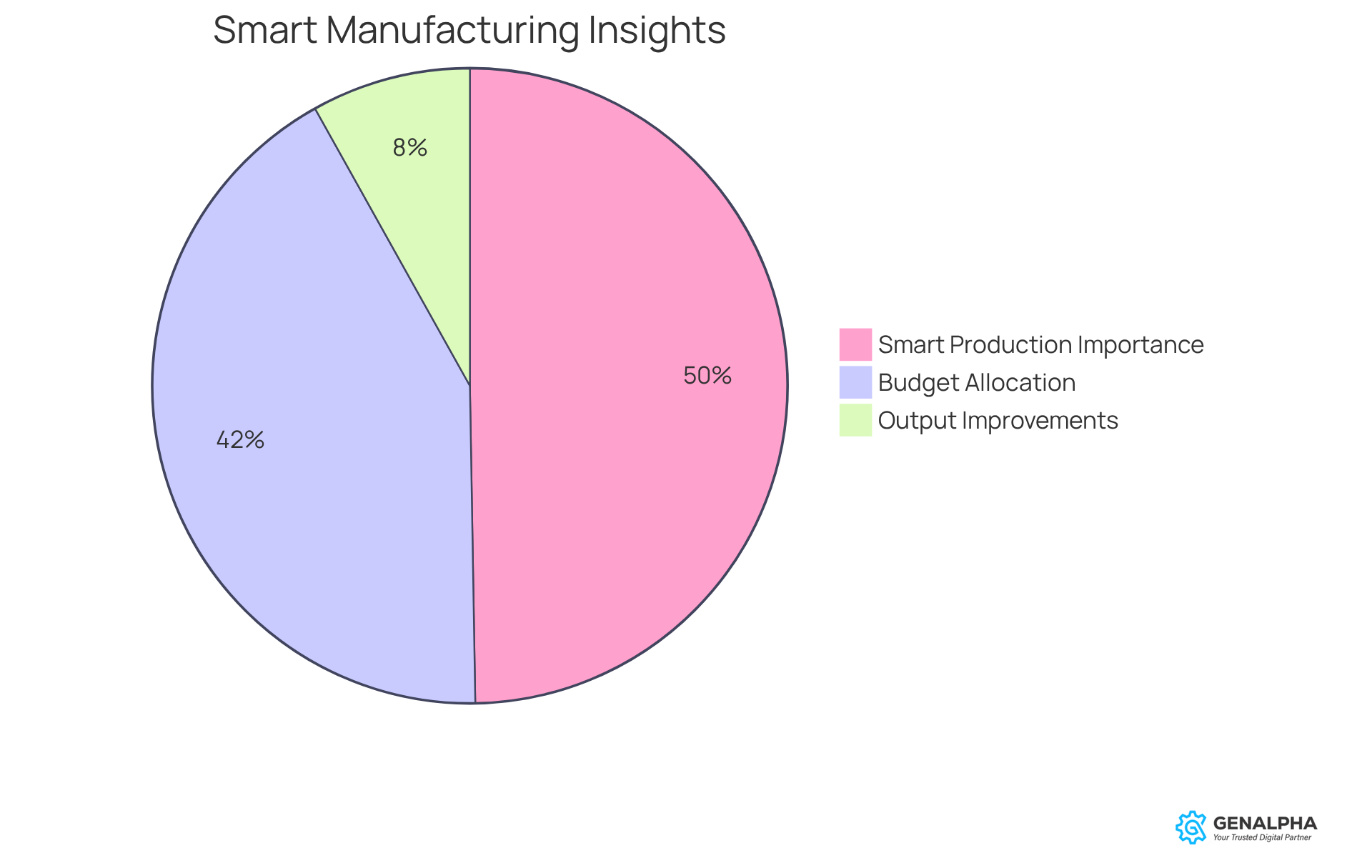

As more producers recognize the importance of smart technologies, Parker’s initiatives reflect a broader trend. Did you know that:

- 92% of producers see smart production as key to staying competitive?

- Tim Gaus puts it perfectly: "Intelligent production is no longer regarded as a future objective—it’s now recognized as a crucial factor for competitive advantage."

- 78% of manufacturers allocating over 20% of their improvement budget into smart manufacturing initiatives?

It’s clear that digital transformation examples in manufacturing are vital for achieving operational excellence and sustained growth.

And here’s the kicker: companies that have embraced smart technologies are seeing production output improvements of 10% to 20%. That’s a tangible benefit of IoT and data analytics in action! So, what do you think? Are you ready to explore how these innovations can elevate your operations?

Conclusion

Digital transformation is really shaking things up in the manufacturing world, bringing in fresh solutions that boost efficiency, safety, and productivity. Just think about it—companies like GenAlpha Technologies, Siemens, and GE Digital are tapping into technology to tackle industry challenges and keep up with what customers want. By using tools like eCommerce platforms, digital twins, and IoT solutions, manufacturers are not just streamlining their operations; they’re setting themselves up for future success.

Take a look at some key examples that show the real benefits of digital transformation in manufacturing:

- Siemens' digital twin technology, for instance, allows for real-time data analysis and predictive maintenance.

- Honeywell’s advanced automation solutions, which really step up safety and efficiency.

- Rockwell Automation and Caterpillar, who are also making waves with smart manufacturing technologies and data analytics that drive operational excellence.

As the manufacturing sector keeps evolving, we can’t overlook how crucial digital transformation is. Organizations that invest in these technologies will not only boost their operational capabilities but also build stronger relationships with customers and promote sustainable growth. The future of manufacturing looks bright for those ready to embrace change and harness the power of digital solutions. So, why not take a moment to think about how your company can leverage these advancements to stay competitive and thrive in this fast-paced environment?

Frequently Asked Questions

What is GenAlpha Technologies known for in the manufacturing industry?

GenAlpha Technologies is recognized for its innovative digital transformation solutions, particularly through its B2B eCommerce platform, Equip360, which optimizes inventory management and enhances online sales performance for equipment manufacturers and distributors.

What features does Equip360 offer to businesses?

Equip360 includes features like digital warranty management and advanced analytics tools, helping businesses streamline operations and improve customer satisfaction.

What is the projected market value for digital transformation in manufacturing by 2035?

The digital transformation market in manufacturing is expected to reach USD 4,275.1 billion by 2035.

How does Equip360 integrate with existing systems?

Equip360 seamlessly integrates with existing ERP systems to provide real-time access to customer-specific pricing, inventory, and order status.

What do industry leaders say about the need for adaptability in the digital age?

Industry leaders emphasize that businesses must embrace change to survive and remain relevant, as noted by figures like John Chambers and Tim O'Reilly.

What is Siemens' approach to enhancing manufacturing efficiency?

Siemens utilizes digital twin technology to create virtual replicas of physical assets, allowing manufacturers to simulate and optimize their processes in a risk-free environment.

How can digital twins impact time-to-market and operational efficiency?

Digital twins can cut time-to-market by up to 50% and help manufacturers predict equipment failures with over 95% accuracy, leading to improved product quality and customer satisfaction.

What challenges do producers face when implementing digital twin technology?

Challenges include interoperability issues and the need for specialized skills, despite the benefits of cost savings and increased planning reliability.

How is GE Digital utilizing IoT in manufacturing?

GE Digital uses IoT sensors and advanced analytics for predictive maintenance, providing manufacturers with real-time insights into equipment health to proactively address maintenance needs.

What are the potential benefits of predictive maintenance in manufacturing?

Predictive maintenance can reduce equipment downtime by up to 30%, leading to significant cost savings and improved reliability in product delivery.

What challenges has GE faced in its digital transformation efforts?

GE has encountered challenges like data silos and the ongoing need for operational efficiency but is addressing these through strategic technology investments.

How does real-time data benefit manufacturers according to GE?

Real-time data insights enhance relationships with clients by providing valuable information that helps optimize their operations and improve service reliability.