Introduction

In the fast-paced world of equipment manufacturing, it’s easy to feel overwhelmed by the pressure to deliver customized solutions while keeping everything running smoothly. Have you ever wondered how some companies seem to manage it all? Enter Engineer to Order (ETO) ERP systems! These tools are not just a trend; they offer a range of benefits that can streamline project management, cut down lead times, and boost customer satisfaction.

But here’s the kicker: even with all these advantages, many manufacturers still find themselves asking, "How can we effectively implement these systems to really make the most of their potential?" This article dives into ten compelling benefits of ETO ERP, shining a light on how these tools can reshape operations and drive success in today’s competitive landscape. So, let’s explore together!

Enhance Project Management with Engineer to Order ERP

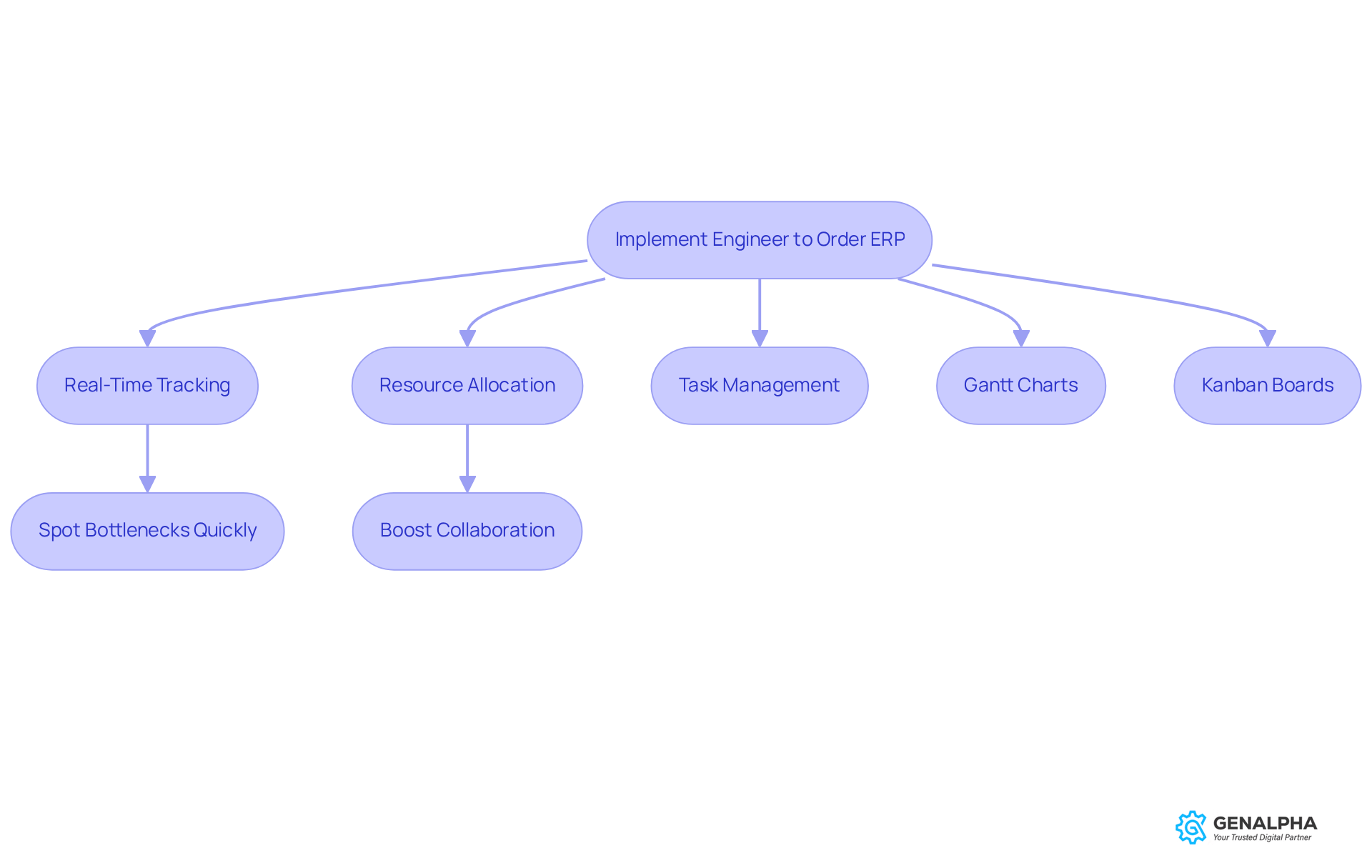

Have you ever felt overwhelmed by project management? Implementing an engineer to order ERP solution can really change the game. It gives producers some pretty advanced tools for real-time tracking, resource allocation, and task management. Imagine being able to develop comprehensive project plans that can quickly adapt to changing client needs - keeping everyone aligned and in the loop throughout the project lifecycle.

For instance, features like Gantt charts and Kanban boards offer visual snapshots of project progress. This means teams can spot bottlenecks quickly and adjust timelines as needed. Real-time insights into project status not only boost collaboration but also enhance decision-making. Producers can tackle issues proactively before they snowball into bigger problems. This is especially crucial in ETO environments, where project complexity and customization require careful oversight.

By leveraging these tools, manufacturers can optimize resource use, cut down lead times, and ultimately boost customer satisfaction. It truly emphasizes the significance of engineer to order ERP in today’s manufacturing landscape. Plus, real-time tracking helps pinpoint bottlenecks right away, allowing for swift action to prevent minor hiccups from turning into major disruptions.

Did you know that 78% of companies reported productivity improvements after adopting ERP solutions? That’s a clear sign of how engineer to order ERP can improve project management efficiency. With real-time visibility, waste is reduced, and efficiency is increased by showcasing resource utilization. It’s an essential part of effective project management that you won’t want to overlook!

Reduce Lead Times through Streamlined Processes

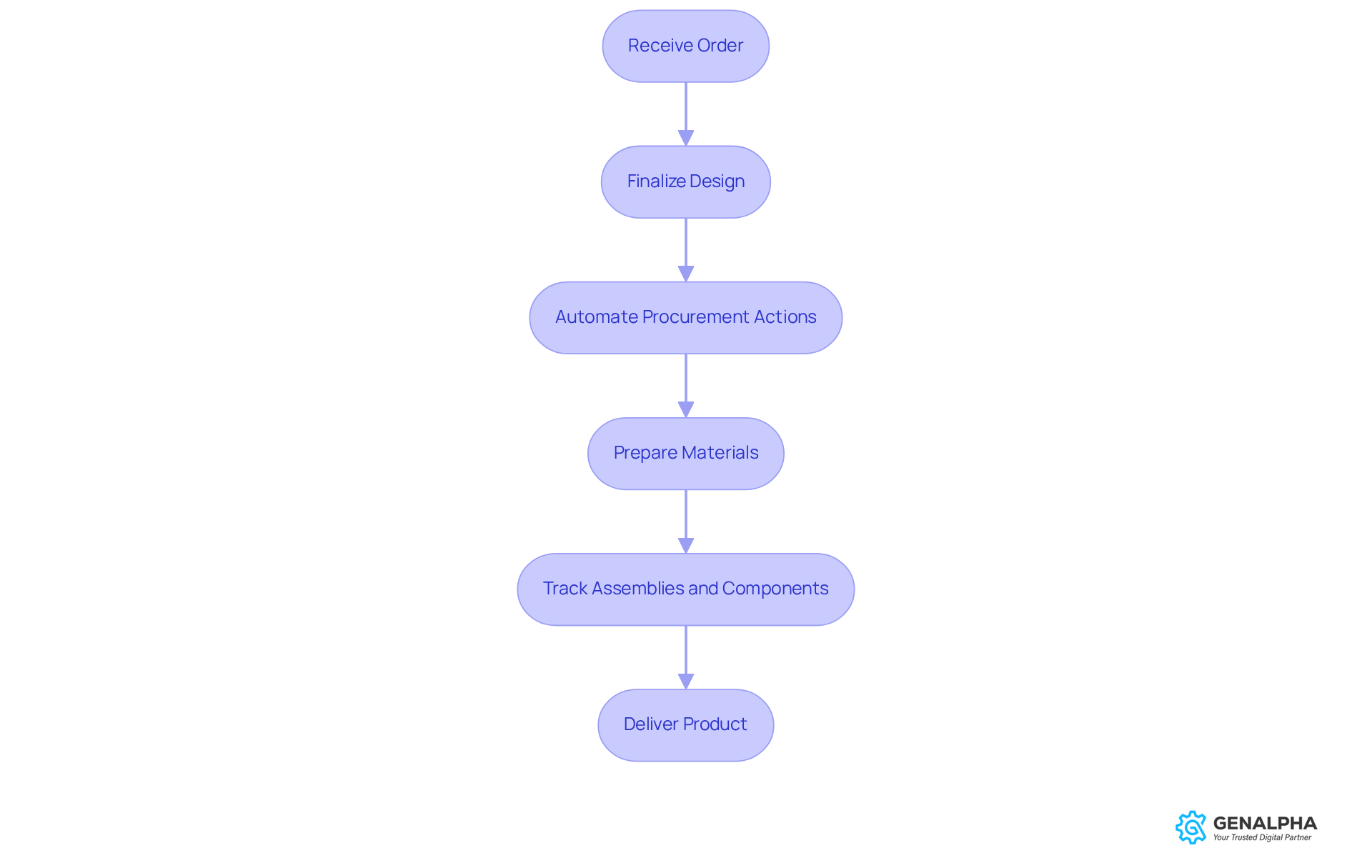

Have you ever felt bogged down by repetitive tasks at work? ETO ERP solutions are here to help! They boost operational efficiency by automating those tedious tasks and promoting smooth communication across departments. Imagine integrating design, procurement, and production functions all in one system. This integration can really cut down the time from when an order is received to when it’s delivered.

For example, think about how automated workflows can kick off procurement actions right after a design is finalized. This means materials are ready when you need them, which can slash lead times by up to 95%! That’s a game changer for producers trying to keep up with market demands. Plus, having real-time visibility into shop-floor operations, goods movement, and labor availability means manufacturers can track assemblies and components throughout the production process, further reducing delays.

Companies that have embraced engineer to order ERP solutions often report significant improvements in project management and operational agility. It’s clear these tools can make a huge difference in the competitive world of equipment manufacturing. And let’s not forget the importance of having a dedicated project manager. They play a crucial role in tracking project progress and ensuring everything runs smoothly.

Regular testing, inspections, and audits are also key to maintaining product quality, which is super important in ETO manufacturing. By focusing on these aspects, the engineer to order ERP solutions not only streamline processes but also enhance overall operational effectiveness. So, why not consider how these solutions could transform your operations?

Achieve Greater Customization for Client Needs

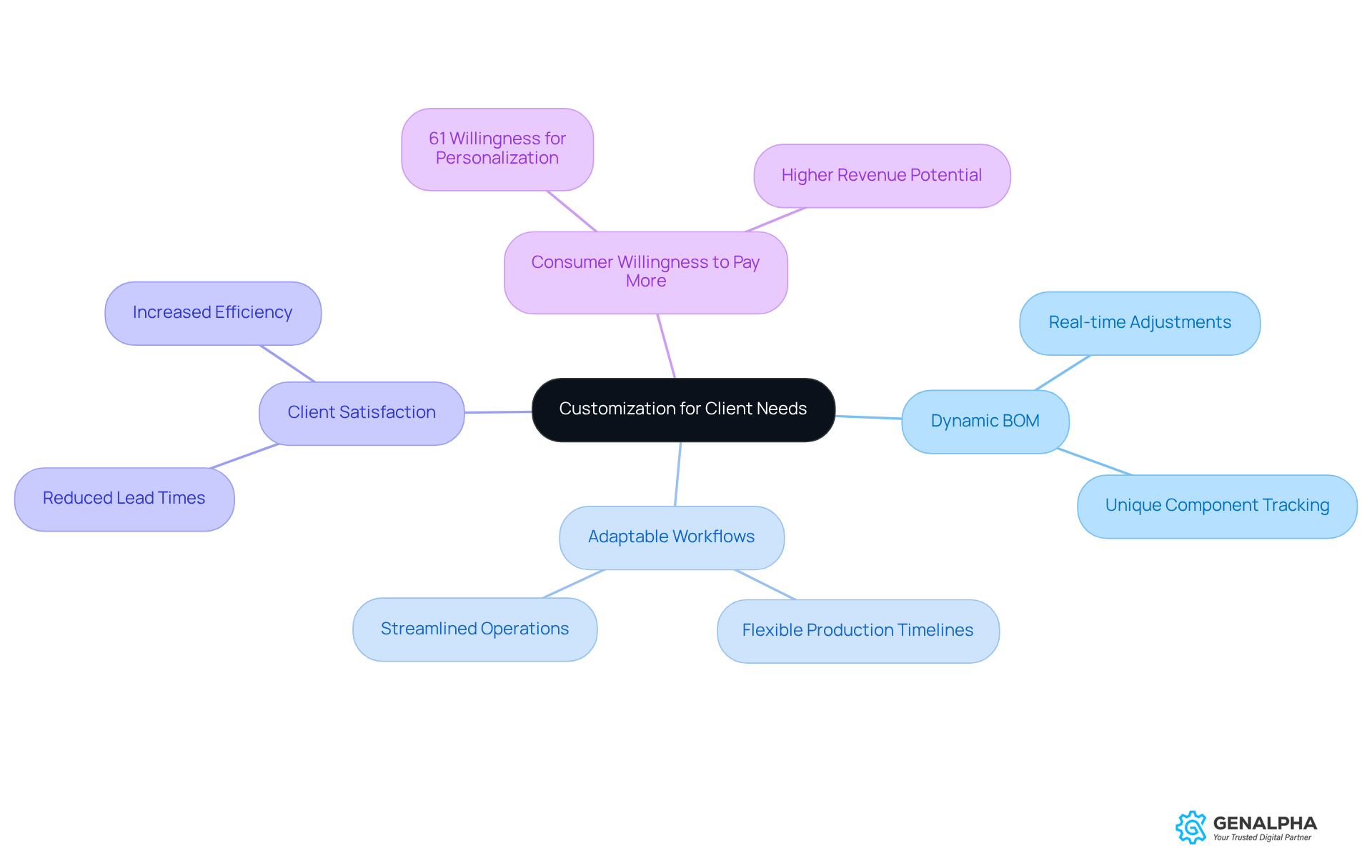

Have you ever considered how an effective engineer to order ERP system can truly transform the game for producers? It’s all about enhancing customization through dynamic bills of materials (BOM) and adaptable workflows. This means producers can quickly adjust to changing client specifications, ensuring the final product is just what the user wanted.

For example, imagine a producer being able to tweak designs and production timelines without breaking a sweat. This not only cuts down on downtime but also boosts efficiency. And let’s be honest, who doesn’t want that? This kind of flexibility streamlines operations and significantly boosts client satisfaction. In fact, studies show that producers utilizing engineer to order ERP experience significant enhancements in project visibility, reduced lead times, cost control, and overall client satisfaction.

Did you know that 61% of consumers are willing to spend more for personalized experiences? That really highlights how crucial customization is in today’s market. By incorporating dynamic BOM features, producers can respond to unique project demands, ultimately delivering tailored solutions that meet the ever-evolving needs of their clients. So, why not take that step towards customization? It could make all the difference!

Integrate Digital Solutions for Operational Efficiency

Integrating digital solutions into an engineer to order ERP framework can significantly enhance operational efficiency. Imagine how smoothly everything could run when sales, engineering, and production are all connected! This integration allows for real-time data sharing, which is super important for making informed decisions and cutting down on errors.

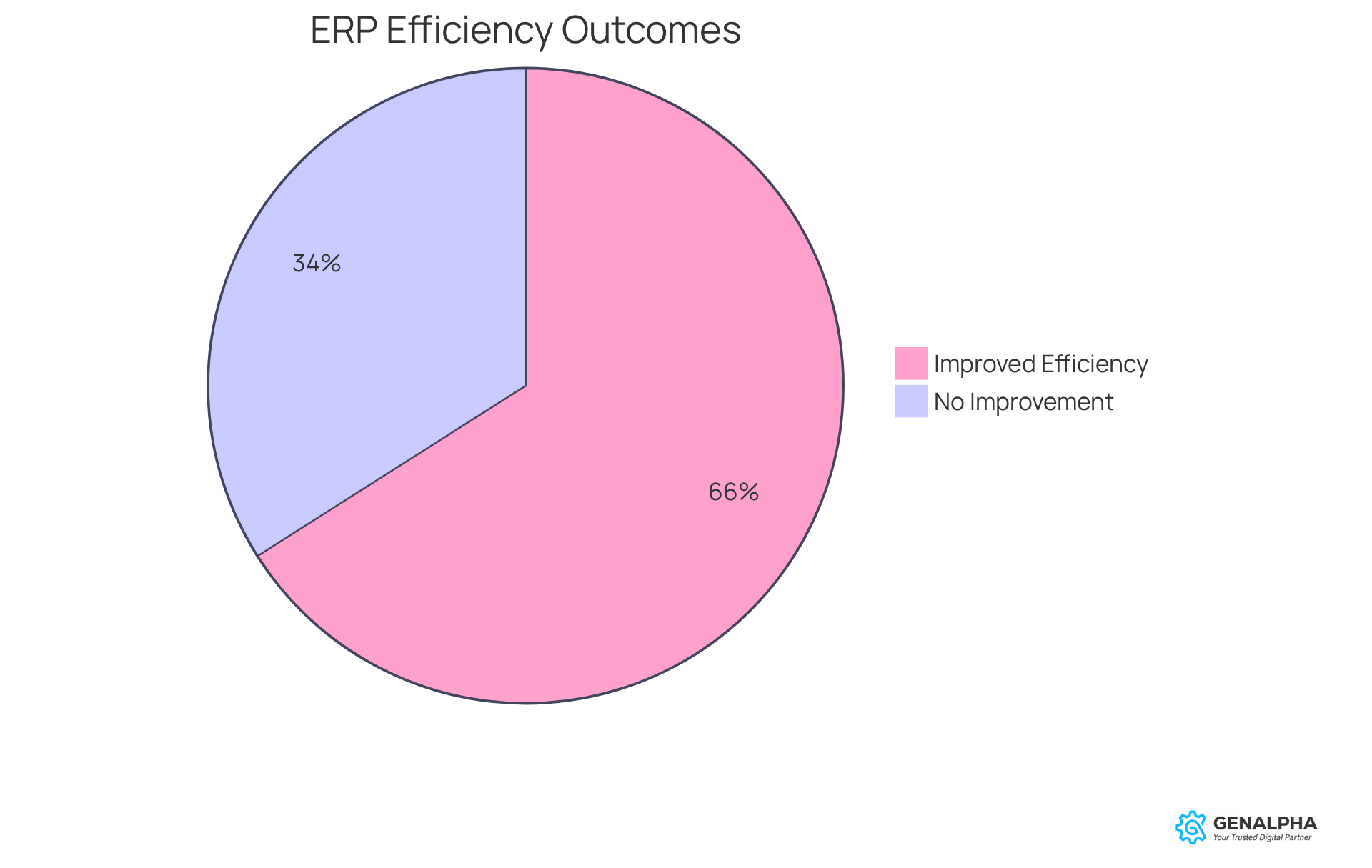

For example, when sales teams have access to live inventory data, they can provide customers with accurate delivery timelines. How great would that be for enhancing the overall customer experience? Plus, did you know that 66% of organizations see improved operational efficiency after implementing ERP? That really highlights how powerful real-time data can be for business processes.

By tapping into these real-time insights, equipment producers can quickly respond to changing conditions, optimize resource allocation, and ultimately drive growth in a competitive marketplace. So, why not consider how these digital solutions could transform your operations?

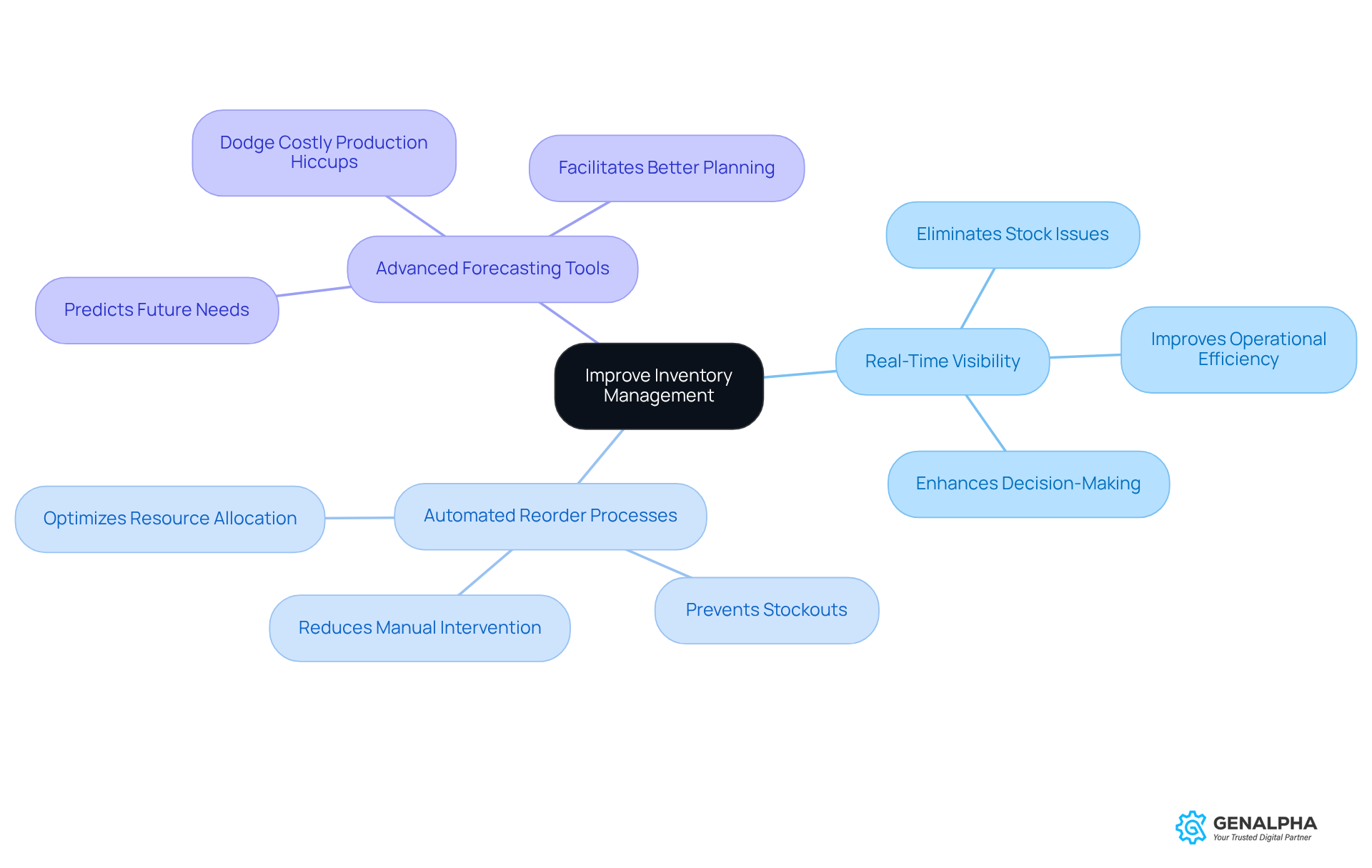

Improve Inventory Management and Control

Ever wondered how an engineer to order ERP system can truly revolutionize inventory management? Picture this: you have real-time visibility into your stock levels, and the system even automates reorder processes for you. Sounds great, right? This means producers can manage their inventory effectively with engineer to order ERP, eliminating worries about running out of stock or having too much on hand.

For example, think about those advanced forecasting tools. They dive into historical data to predict what you’ll need in the future. This way, manufacturers can plan ahead and dodge those costly production hiccups. So, why not take a closer look at how this could work for you? It might just be the solution you didn’t know you needed!

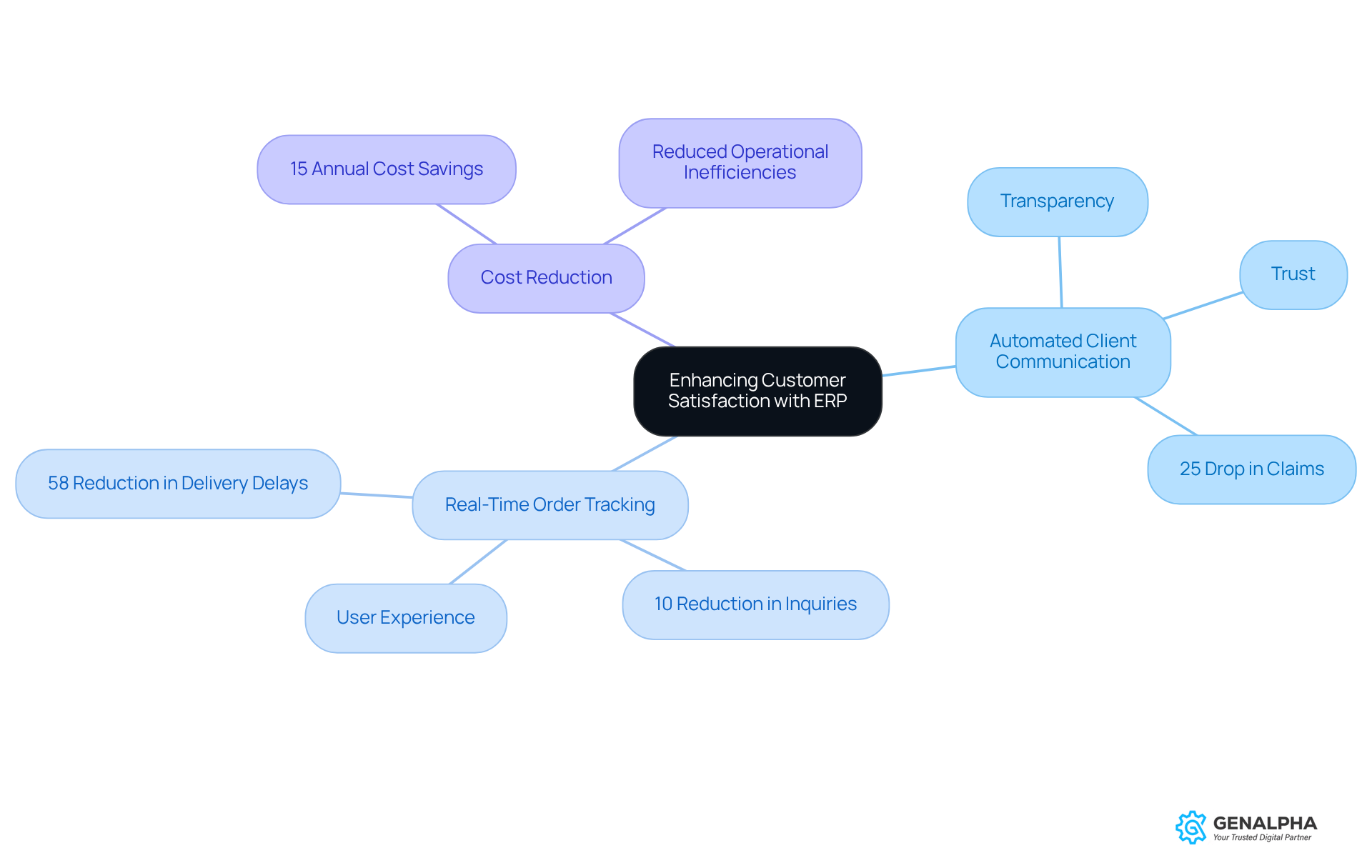

Enhance Customer Satisfaction with Efficient Service

Have you ever wondered how engineer to order ERP systems can really enhance client satisfaction? Well, they play a vital role in making service processes smoother and more efficient. Think about it: features like automated client communication and real-time order tracking keep clients in the loop throughout the entire order lifecycle. For example, when clients receive automated notifications about order status changes, it not only creates transparency but also builds trust between manufacturers and their clients.

And here’s something interesting: statistics show that implementing real-time tracking can cut operational costs by up to 15% and reduce inquiries by 10%. That’s a win-win, right? Not only do you save money, but you also enhance the user experience. Plus, companies that use automated communication have seen a 25% drop in claims, proving that proactive updates can really elevate service quality.

By leveraging engineer to order ERP, ETO producers can effectively manage customer expectations and boost overall satisfaction. This ultimately leads to stronger customer relationships and increased loyalty. So, why not consider how these systems could transform your approach to client interactions?

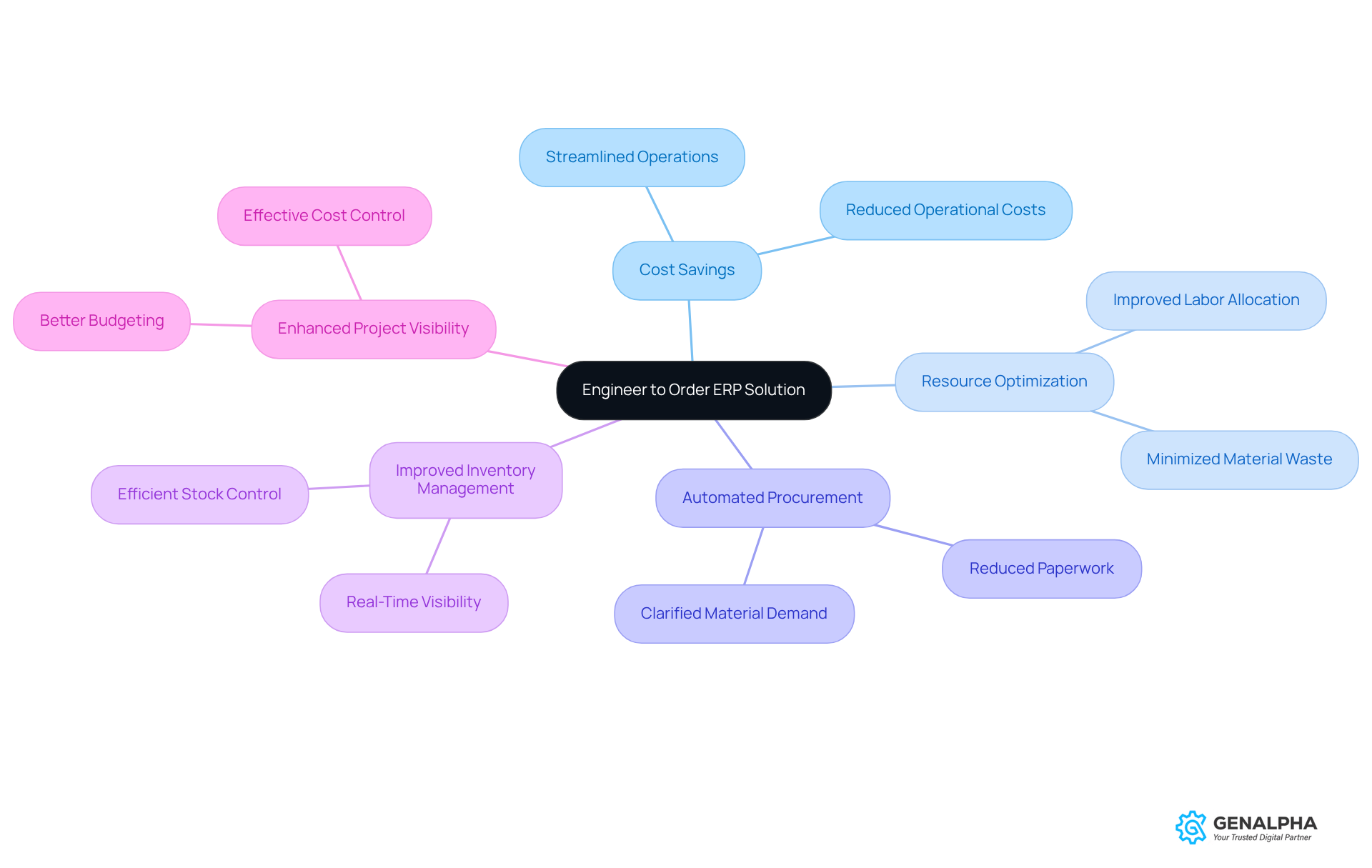

Realize Cost Savings and Increased Profitability

Are you considering the implementation of an engineer to order ERP solution? You might be surprised at how much it can save you! By optimizing resource allocation and cutting down on waste, businesses can really see some significant cost savings. For instance, when you automate procurement processes and improve inventory management, you’re not just streamlining operations - you’re also slashing those pesky operational costs.

But that’s not all! Enhanced project visibility plays a huge role here, too. It allows for better budgeting and cost control, which can ultimately boost your profitability. So, why not take a closer look at how engineer to order ERP solutions could benefit you? It might just be the game-changer you’ve been looking for!

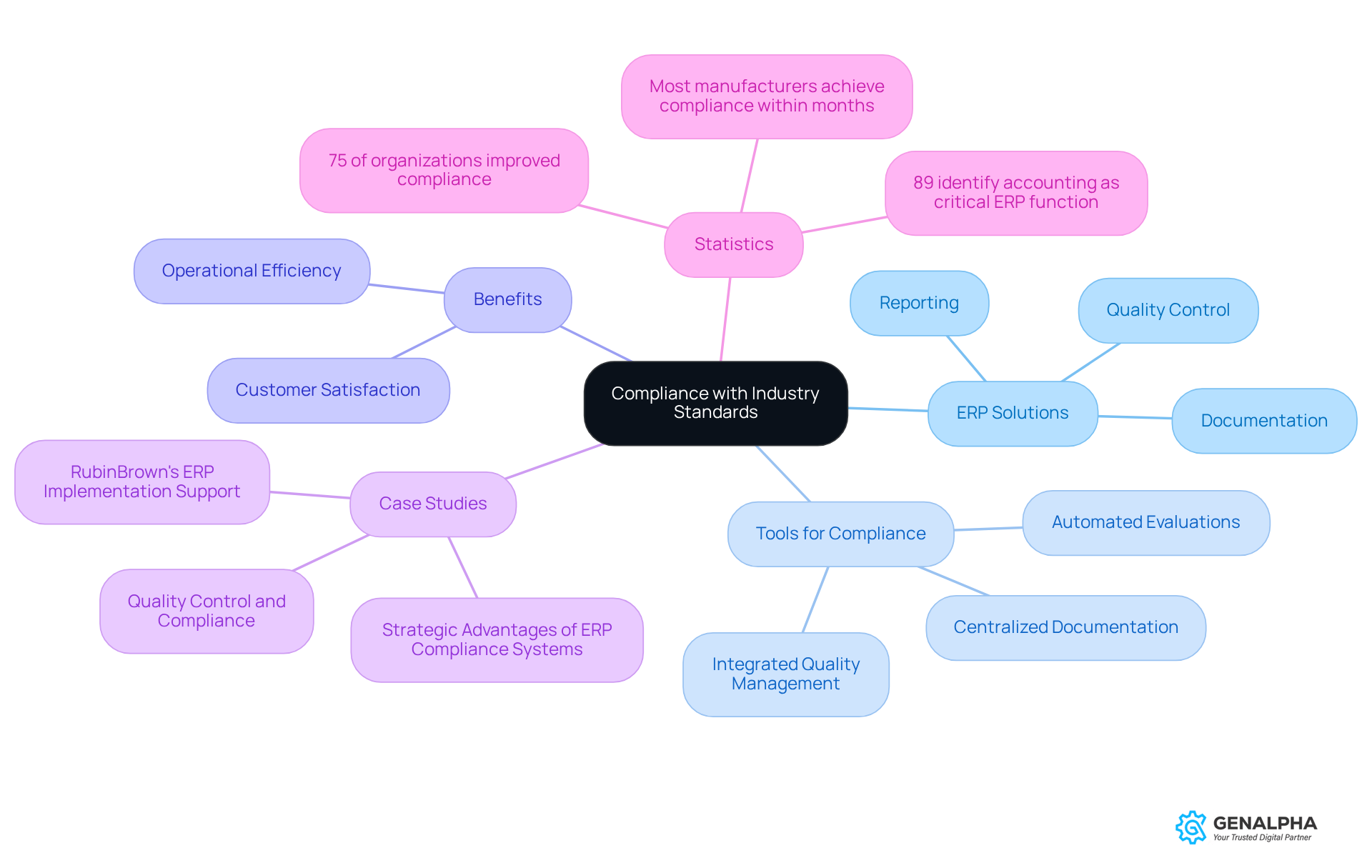

Ensure Compliance with Industry Standards

Have you ever wondered how producers keep up with all those industry standards? Well, solutions for engineer to order ERP are here to help! They come packed with tools for documentation, reporting, and quality control that make compliance a breeze. Imagine automating evaluations and generating reports without breaking a sweat - sounds great, right? This not only takes the pressure off regulatory adherence but also boosts operational efficiency.

For example, think about those integrated quality management features. They meticulously track product specifications, ensuring that everything produced meets the required standards. This proactive approach minimizes the risk of non-compliance and keeps things running smoothly.

A case study highlights how producers who weave quality assurance into their ERP solutions have successfully prevented defects. The result? Happier customers and a stronger position in the market! Plus, did you know that 75% of organizations have improved compliance thanks to ERP solutions? Most producers even achieve basic compliance within just a few months of launching.

By utilizing engineer to order ERP, producers can confidently navigate the tricky regulatory landscape. So, why not take the leap? Embrace these solutions and watch your growth and sustainability soar!

Scale Operations to Meet Market Demands

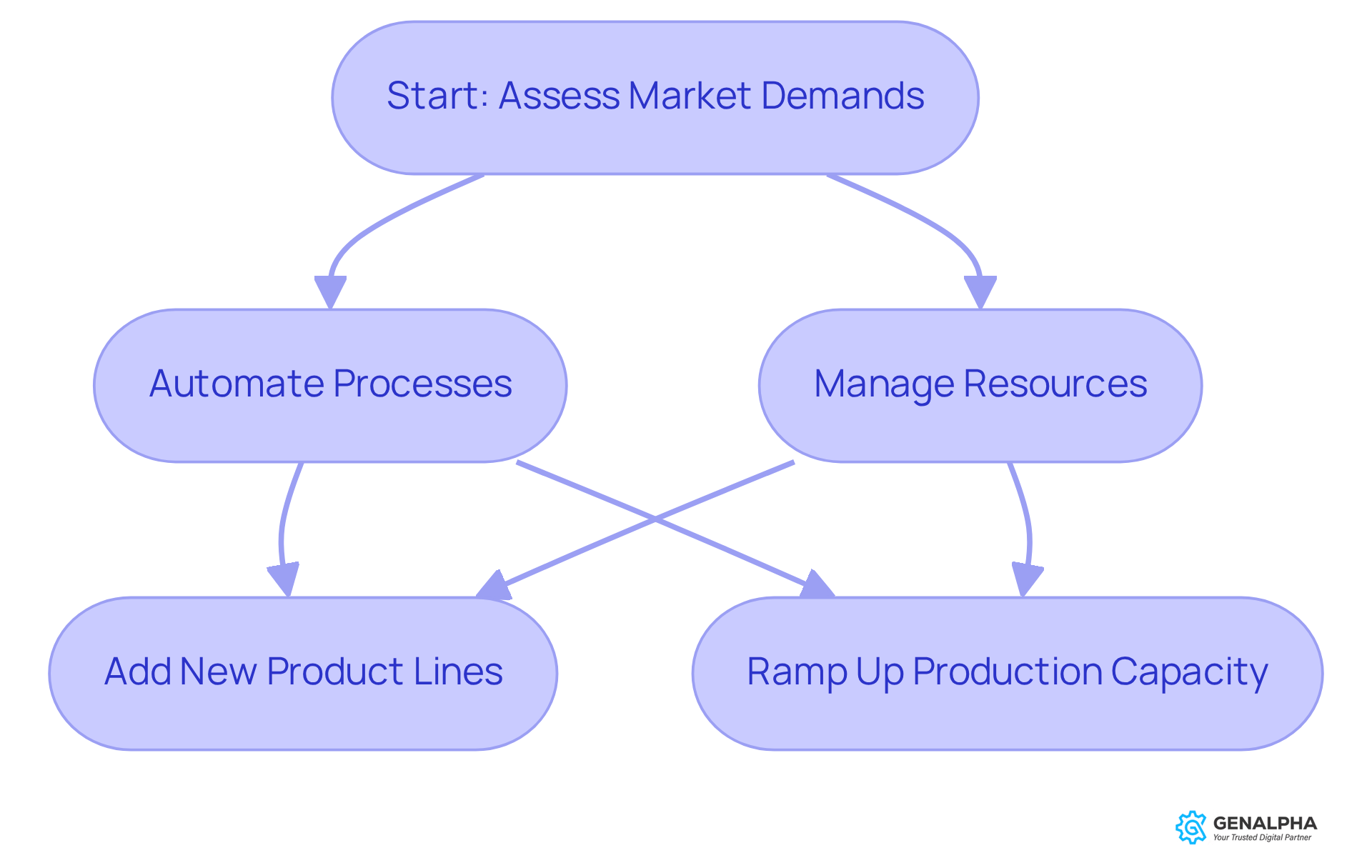

Ever thought about how an engineer to order ERP can really change the game for your operations? It’s all about flexibility! Imagine being able to scale your production effortlessly. By automating processes and managing resources better with engineer to order ERP, you can quickly adjust your production levels to meet market demands.

For instance, think about how easy it would be to add new product lines or ramp up production capacity without causing major disruptions. This means you can jump on growth opportunities as they pop up! So, how can you take advantage of this kind of solution in your own business?

Leverage Data-Driven Insights for Better Decision-Making

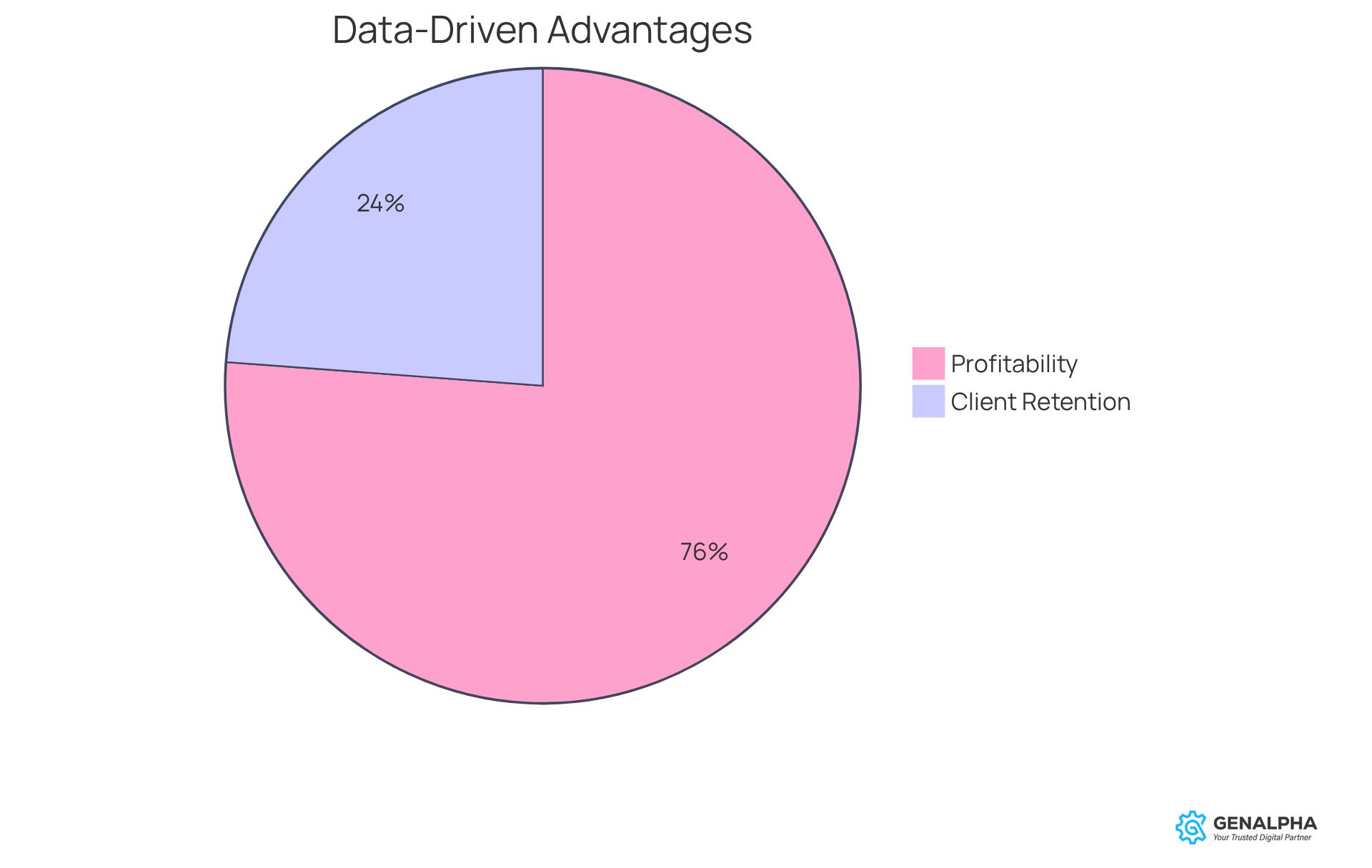

Have you ever wondered how some companies seem to have a magic touch when it comes to making smart decisions? Well, engineer to order ERP systems are designed to help! These systems come packed with powerful analytics tools that let producers tap into their data for better decision-making. By diving into production metrics, client feedback, and market trends, manufacturers can spot areas that need a little TLC and make strategic tweaks.

For example, imagine having real-time dashboards that display key performance indicators (KPIs). This way, management can easily gauge how well operations are running and how happy clients are. Did you know that data-driven organizations are 19 times more likely to be profitable and six times more likely to keep their clients? That really highlights how crucial data is for operational success!

Take N&N Moving Supplies, for instance. After implementing ERP, they slashed their payroll processing time by a whopping 84%! Companies like this have seen significant perks, including boosted profits and a better understanding of their customers, by implementing engineer to order ERP. So, to really make the most of these benefits, manufacturers should regularly check in on their analytics tools to ensure they’re using data to its fullest potential. What do you think? Are you ready to harness the power of data?

Conclusion

Implementing an Engineer to Order (ETO) ERP solution brings some serious perks for equipment manufacturers. It really amps up project management, boosts operational efficiency, and keeps customers happy. With advanced tools and real-time insights, manufacturers can streamline their processes, cut down lead times, and adapt to client needs with impressive agility. This kind of flexibility not only improves collaboration and decision-making but also helps companies thrive in a competitive market.

So, what are the key advantages of ETO ERP systems? Well, they:

- Enhance project management capabilities

- Reduce lead times through streamlined processes

- Allow for greater customization for clients

- Integrate digital solutions for better inventory management and operational efficiency

- Provide data-driven insights that can significantly boost decision-making and profitability

All these elements come together to create a more responsive and effective manufacturing operation.

As the manufacturing industry keeps evolving, embracing an Engineer to Order ERP system isn’t just a smart move; it’s a must for anyone wanting to stay ahead of the game. By investing in these solutions, manufacturers can meet current market demands and even anticipate future challenges, ensuring they keep growing and succeeding. So, why wait? Now’s the time to explore the potential of ETO ERP and unlock the capabilities that will drive innovation and efficiency in your operations!

Frequently Asked Questions

What is engineer to order (ETO) ERP and how can it enhance project management?

Engineer to order ERP is a solution designed to improve project management by providing advanced tools for real-time tracking, resource allocation, and task management. It allows manufacturers to develop flexible project plans that adapt to changing client needs, ensuring team alignment throughout the project lifecycle.

What features of ETO ERP facilitate project tracking and management?

Features such as Gantt charts and Kanban boards provide visual snapshots of project progress, enabling teams to quickly identify bottlenecks and adjust timelines. Real-time insights into project status enhance collaboration and decision-making, allowing producers to proactively address issues.

How does ETO ERP contribute to reducing lead times?

ETO ERP solutions streamline processes by automating repetitive tasks and integrating design, procurement, and production functions. This integration allows for automated workflows that can kick off procurement actions immediately after design finalization, significantly reducing lead times by up to 95%.

What role does real-time visibility play in ETO ERP solutions?

Real-time visibility into shop-floor operations, goods movement, and labor availability helps manufacturers track assemblies and components throughout the production process, further reducing delays and enhancing operational efficiency.

How does an ETO ERP system enhance customization for client needs?

An effective ETO ERP system allows for dynamic bills of materials (BOM) and adaptable workflows, enabling producers to quickly adjust to changing client specifications. This flexibility improves operational efficiency and boosts client satisfaction.

What are the benefits of using dynamic BOM features in ETO ERP?

Dynamic BOM features allow producers to respond to unique project demands, ensuring tailored solutions that meet evolving client needs. This capability leads to significant enhancements in project visibility, reduced lead times, and improved cost control.

What impact does ETO ERP have on overall operational effectiveness?

Companies that implement ETO ERP solutions often report significant improvements in project management, operational agility, and product quality. Regular testing, inspections, and audits contribute to maintaining high standards in ETO manufacturing.

How important is a dedicated project manager in the context of ETO ERP?

A dedicated project manager plays a crucial role in tracking project progress and ensuring smooth operations, which is essential for maintaining efficiency and meeting client expectations in ETO environments.