Overview

Have you ever thought about how digital transformation is shaking up the manufacturing world? It’s pretty exciting! For equipment makers, this shift brings a treasure trove of benefits—think enhanced operational efficiency, cost savings, and smarter decision-making.

Imagine a factory where machines talk to each other, predicting when they might need a little TLC. Technologies like predictive maintenance and digital twin technology are making this a reality. They help significantly reduce downtime and optimize how resources are allocated. This means that manufacturers can stay competitive in a market that’s always evolving.

So, why should you care? Well, these advancements not only streamline operations but also empower you to make informed choices that can drive your business forward. In a nutshell, embracing these technologies could be your ticket to staying ahead in the game.

Are you ready to dive into the digital age of manufacturing? Let’s explore how these innovations can transform your operations!

Introduction

The manufacturing landscape is experiencing a major shift, thanks to digital transformation taking center stage. It’s reshaping how equipment makers operate, and let me tell you, this evolution is packed with opportunities! We’re talking about:

- Enhanced efficiency

- Cost savings

- Better decision-making

- Sustainability practices

Sounds great, right?

But hold on a second—this journey isn’t all smooth sailing. Many producers are facing some real challenges, like:

- Integration hurdles

- Implementation costs

- Pressing need for skilled personnel

So, how can manufacturers navigate these complexities? How can they tap into the full benefits of digital transformation and stay competitive in a market that’s changing faster than ever? Let’s dive in together!

GenAlpha Technologies: Streamline Operations with Advanced Digital Solutions

At GenAlpha Technologies, we understand the challenges that producers and suppliers face in today’s fast-paced market. That's why we offer a wide range of sophisticated online solutions tailored just for you. Our flagship product, Equip360, is designed to significantly enhance your operational efficiency. Imagine optimizing your inventory management and boosting your online sales capabilities all in one go!

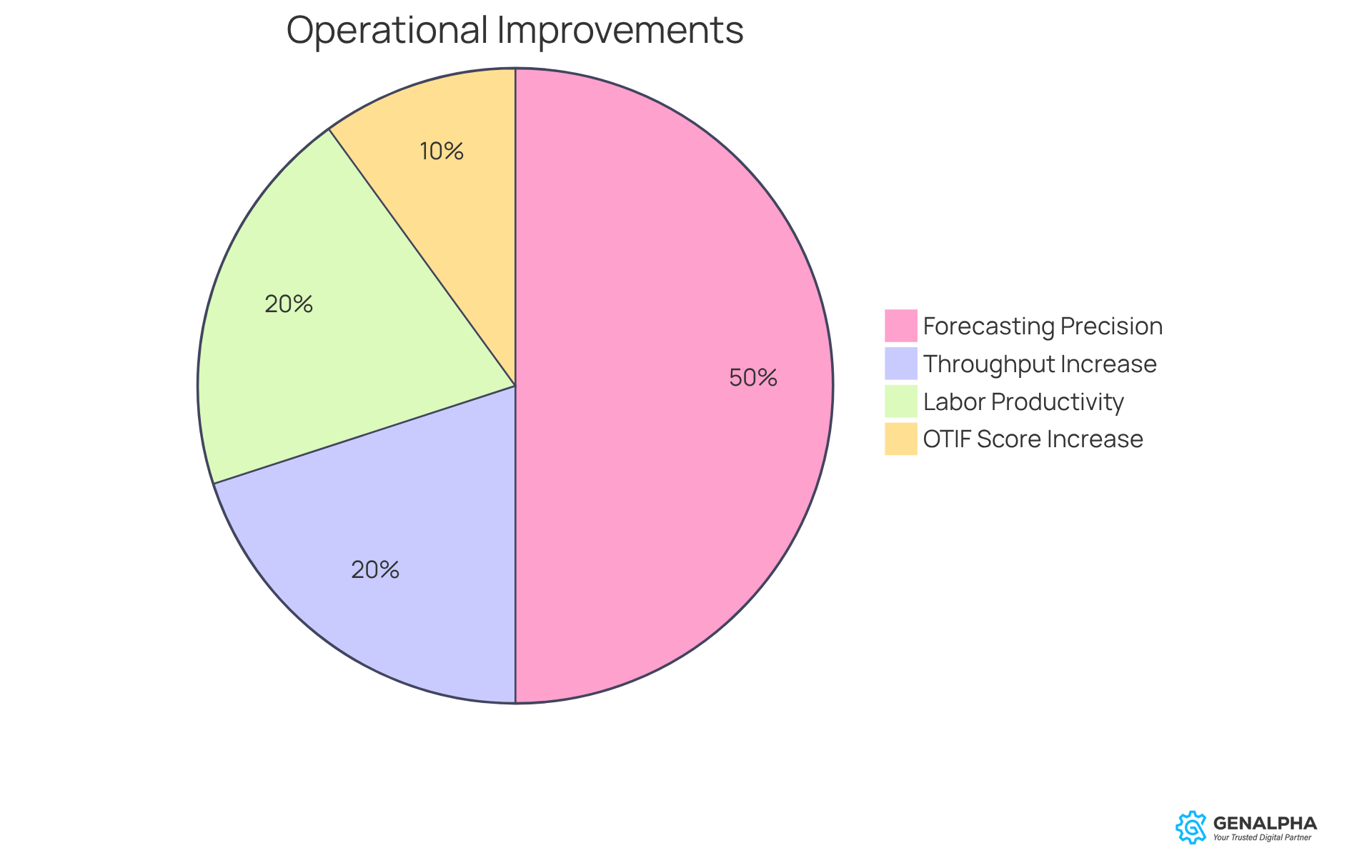

Equip360 seamlessly merges with your current ERP systems, making the transition into the online environment smooth and easy. This alignment with modern customer expectations is crucial. Did you know that producers investing in such innovations can see a 10% to 30% rise in throughput? Plus, labor productivity can improve by 15% to 30%, and OTIF scores can jump by around 10 percentage points on average. That’s a significant boost!

But there’s more—Equip360 also enhances forecasting precision for producers by up to 85%. This means you can predict market demands more effectively and optimize your supply chains. However, we know that the journey isn’t without its bumps. Many producers face high implementation costs and concerns about data protection, which can slow down technological transformation initiatives.

As the industry evolves, the digital transformation of manufacturing through solutions like Equip360 isn’t just a nice-to-have; it’s essential for staying competitive and driving growth. So, why wait? Let’s talk about how Equip360 can help you thrive in this digital age!

Enhanced Efficiency: Optimize Manufacturing Processes for Greater Output

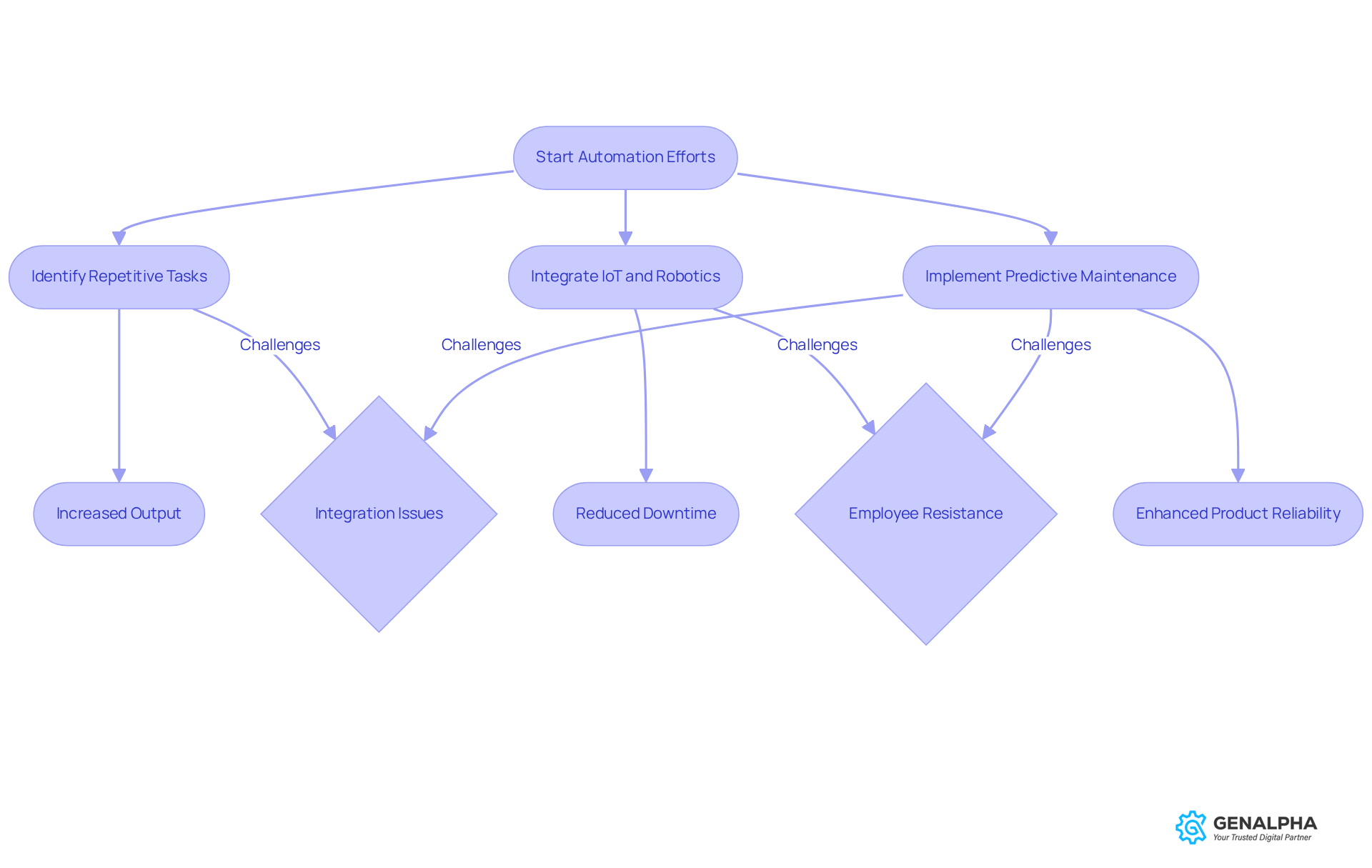

Have you ever thought about how the digital transformation of manufacturing can truly change the game for producers? It’s all about automating those repetitive tasks and streamlining workflows, which can seriously boost operational efficiency. By bringing in advanced technologies like robotics and IoT devices, companies can cut down on production times and minimize errors.

For example, imagine IoT sensors keeping an eye on machine performance in real-time. This means predictive maintenance can kick in, preventing those costly downtimes and ensuring consistent quality. Sounds great, right? This proactive approach doesn’t just ramp up output; it also enhances product reliability, leading to happier customers and greater loyalty.

Did you know the global industrial automation market is set to hit a whopping $379 billion by 2030? That’s a growth rate of 9.3%, all thanks to these innovative solutions. And here’s something interesting: 88% of employees say they feel more satisfied and less stressed because of automation taking over those tedious tasks. In finance, positivity jumped from 66% to 89% after automation was introduced.

However, it’s not all smooth sailing. Producers face challenges like integration issues, process complexity, employee resistance, and a lack of training when rolling out these technologies. But if they leverage these advancements wisely, particularly through the digital transformation of manufacturing, they can optimize processes, meet rising product demands, and keep a competitive edge in the market.

So, what’s the best way to start? It’s simple: begin small with automation efforts and gradually scale up. This approach can help producers maximize the benefits without feeling overwhelmed. What do you think—are you ready to embrace automation?

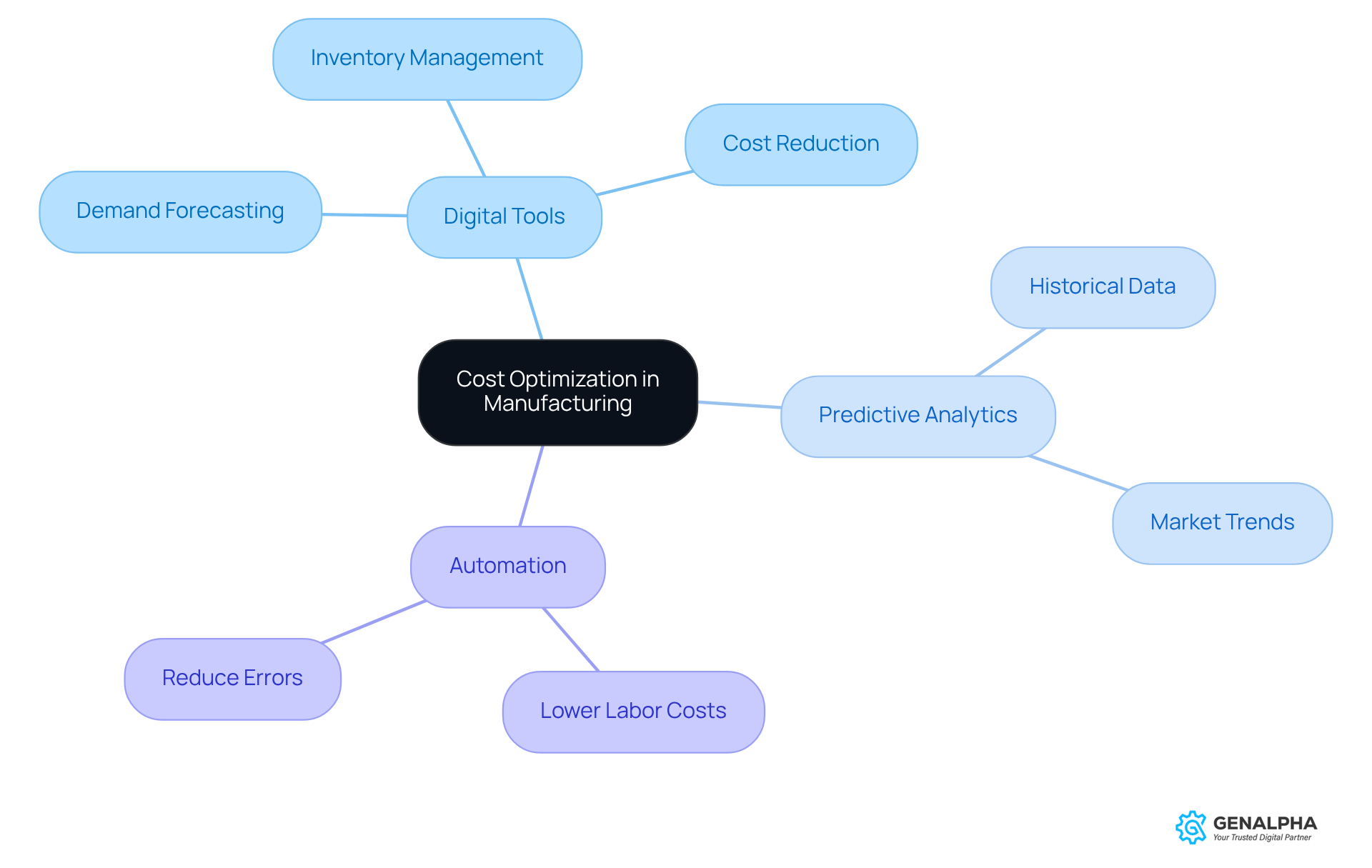

Cost Optimization: Reduce Operational Expenses with Digital Tools

Digital tools are game-changers for the digital transformation of manufacturing, helping manufacturers spot inefficiencies and cut down on waste. Take predictive analytics, for example. It boosts demand forecasting accuracy, which means better inventory management and lower holding costs. By tapping into historical sales data and market trends, businesses can fine-tune their stock levels, reducing excess inventory and the risk of running out of products. This approach not only streamlines operations but also leads to significant savings through the digital transformation of manufacturing. In fact, many companies report a drop in operational costs of 15-20% within the first year of rolling out comprehensive financial analysis programs.

But that’s not all—automation is a key player here too. It helps lower labor costs and reduce human errors, leading to even more savings over time. The digital transformation of manufacturing enables manufacturers that blend predictive insights with automation to achieve up to 30-40% greater efficiency in expenses compared to traditional methods, and they often see labor savings that are three times higher than what they’d get through conventional approaches. For instance, a semiconductor company that adopted predictive inventory management tools saw a 25% cut in procurement costs and a 30% drop in production costs within just six months. This really highlights how powerful integrating predictive insights can be for inventory management.

Moreover, linking predictive analysis to the digital transformation of manufacturing and broader supply chain goals, such as lean operations and improved customer satisfaction, is crucial for maximizing its benefits. Manufacturers should consider investing in training and data literacy to empower their teams to effectively leverage predictive analytics in inventory management. This investment can significantly boost efficiency and profitability in a competitive landscape.

So, how ready are you to embrace these digital tools and take your operations to the next level?

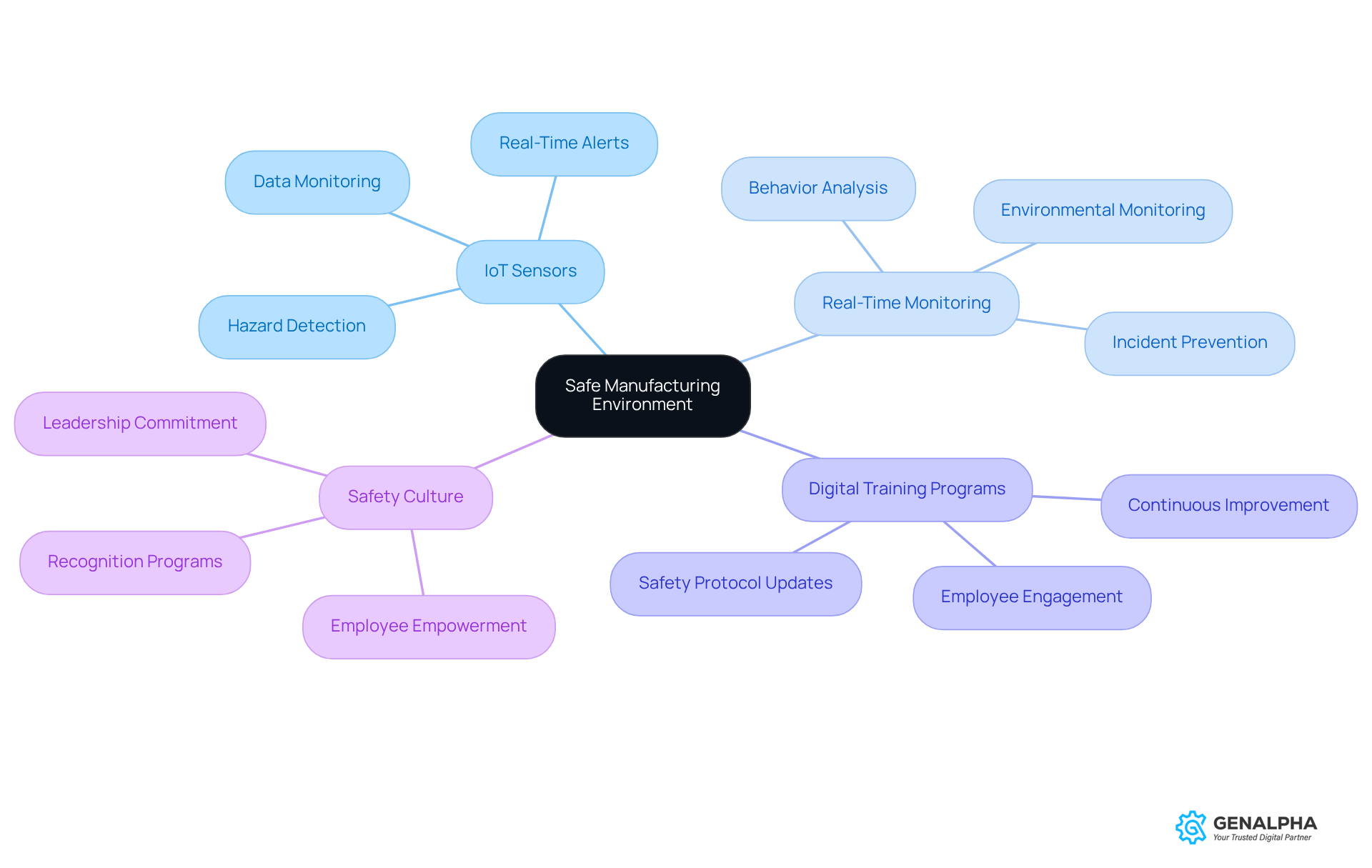

Safe Manufacturing Environment: Leverage Technology for Workplace Safety

Have you ever thought about how technology can make our workplaces safer? Implementing electronic solutions like IoT sensors and real-time monitoring systems can really boost workplace safety. Imagine a scenario where these technologies detect hazardous conditions and alert employees before an accident happens. Sounds great, right?

Additionally, digital training programs can play a crucial role in ensuring that everyone on the team is up-to-date with safety protocols. This not only helps in preventing accidents but also fosters a culture of safety within the organization. So, why not take that step towards a safer workplace? Let's embrace these innovations together!

Improved Decision-Making: Utilize Data Analytics for Strategic Insights

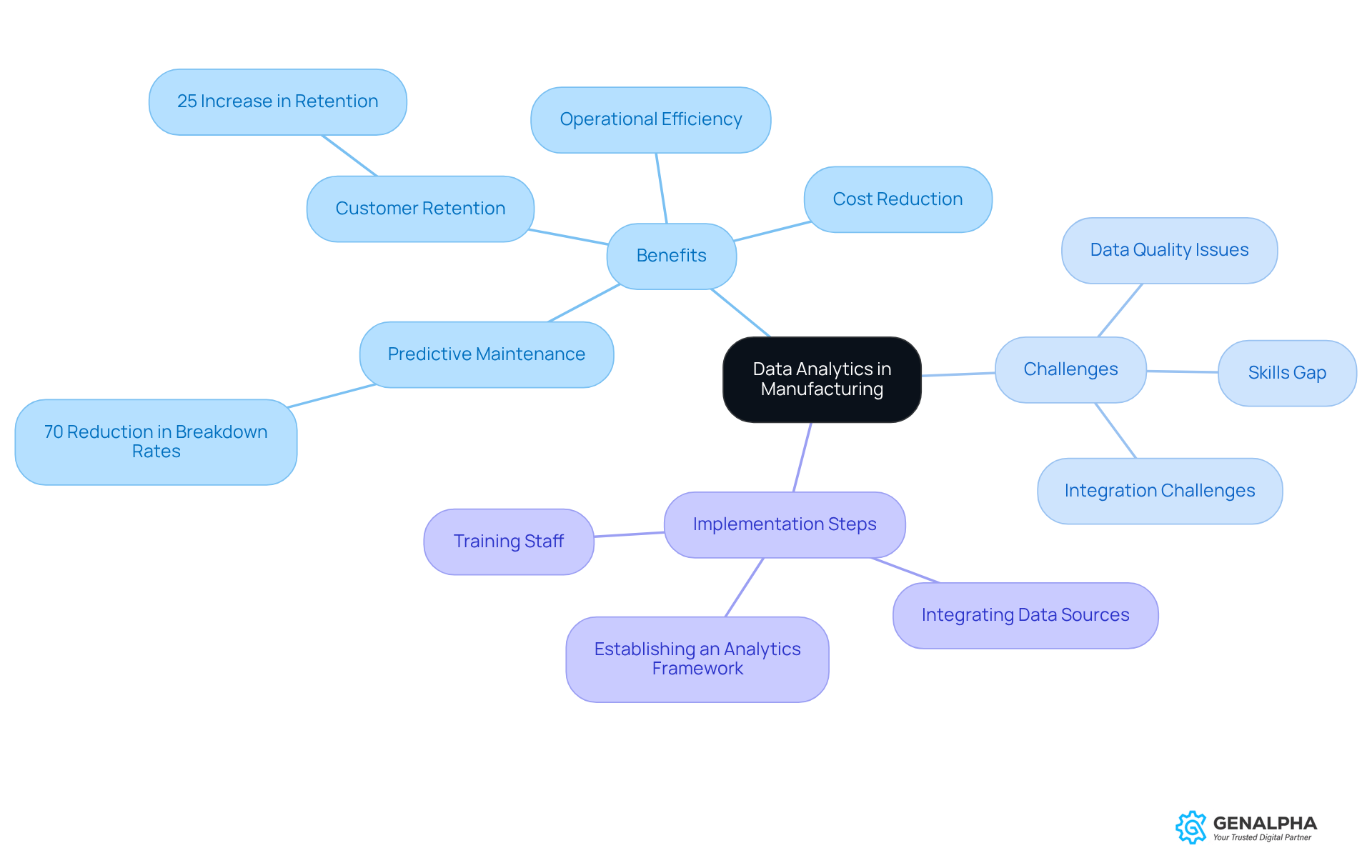

Have you ever wondered how manufacturers can truly harness the power of their operations? Well, the integration of data analysis tools is the key! By diving deep into production data, companies can spot trends, accurately forecast demand, and optimize resource allocation, all of which are critical to the digital transformation of manufacturing. This strategic approach not only ramps up operational efficiency but also ensures that production meets market needs, ultimately driving profitability.

For example, did you know that predictive maintenance data analysis can cut breakdown rates by up to 70% and lower service costs by as much as 23%? That’s a significant boost to uptime and operational effectiveness! And it doesn’t stop there. Organizations that tap into customer experience data often see impressive gains in engagement and satisfaction. In fact, businesses have found that personalized experiences can lead to a 25% increase in customer retention.

As more producers embrace these data analysis features, they’re gearing up for the digital transformation of manufacturing, allowing them to respond proactively to market changes, paving the way for ongoing growth and a competitive edge. But it’s not all smooth sailing—challenges like data quality issues and a skills gap in analysis can throw a wrench in the works.

So, how can producers start using data analytics effectively? It all begins with establishing a solid analytics framework that seamlessly integrates with their current systems. With the right tools in place, the journey toward data-driven success is well within reach!

Increased Competitiveness: Stay Ahead in the Evolving Market Landscape

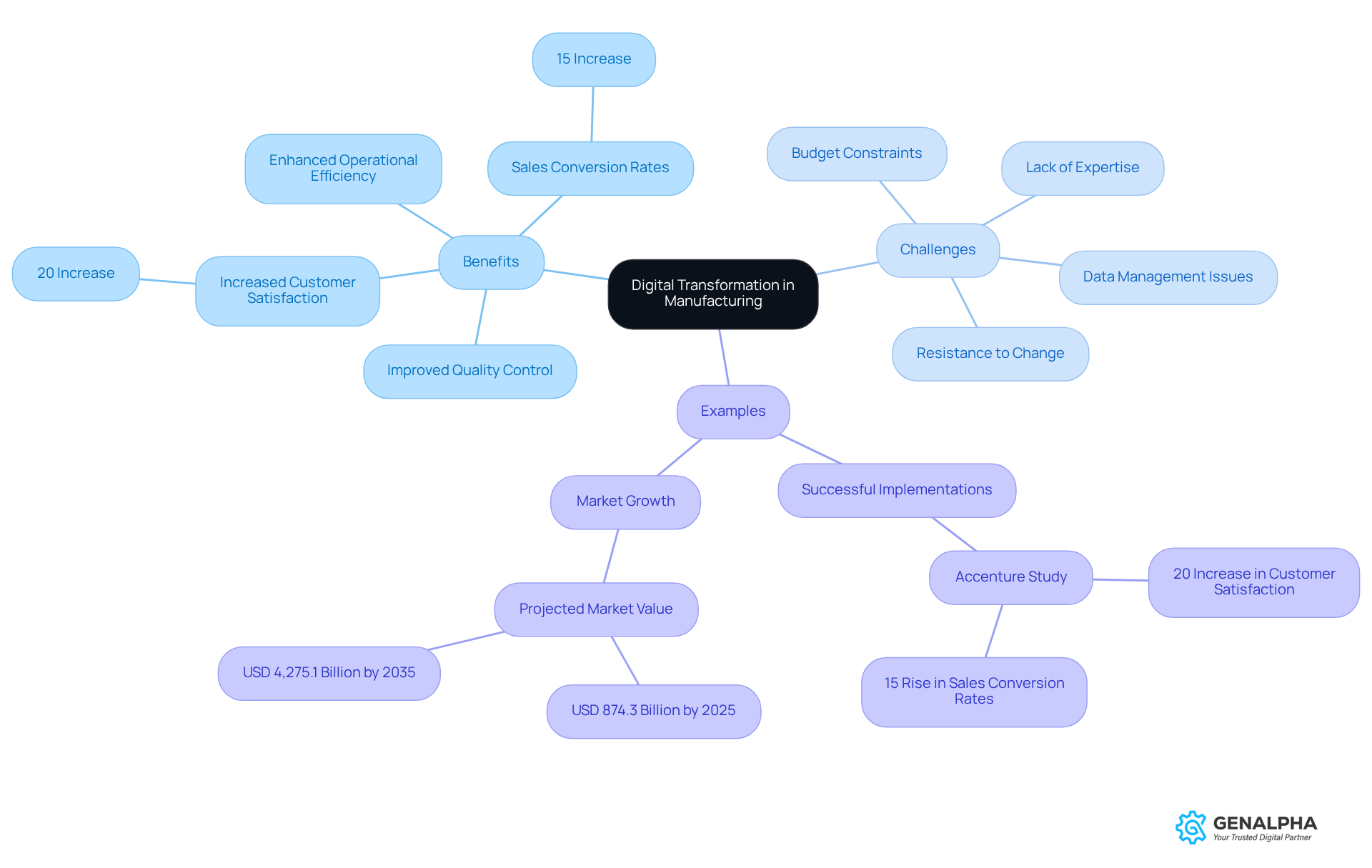

The digital transformation of manufacturing is like having a superpower for producers, allowing them to quickly adapt to market changes with the right tools and technologies. By embracing innovative solutions, companies can not only enhance their product offerings but also significantly boost customer engagement. This agility helps keep existing customers happy while also attracting new ones, driving sustained growth in a competitive landscape.

For example, organizations that have jumped on digital sales strategies have seen impressive results—like a 20% increase in customer satisfaction and a 15% rise in sales conversion rates, according to Accenture. Plus, when advanced technologies like AI and IoT come into play, producers can fine-tune their operations, becoming even more responsive to customer needs and market demands. This means they’re better equipped to tackle challenges and seize opportunities, ensuring they stay at the forefront of their industries.

But let’s be real—many producers face significant hurdles on their digital transformation of manufacturing journeys, such as budget constraints and a lack of internal expertise. A McKinsey survey highlights that a whopping 92% of companies expect to change their business models due to the digital transformation of manufacturing, emphasizing how crucial it is to embrace these changes. So, are you ready to take the plunge into digital transformation?

Sustainability: Implement Eco-Friendly Practices through Digital Solutions

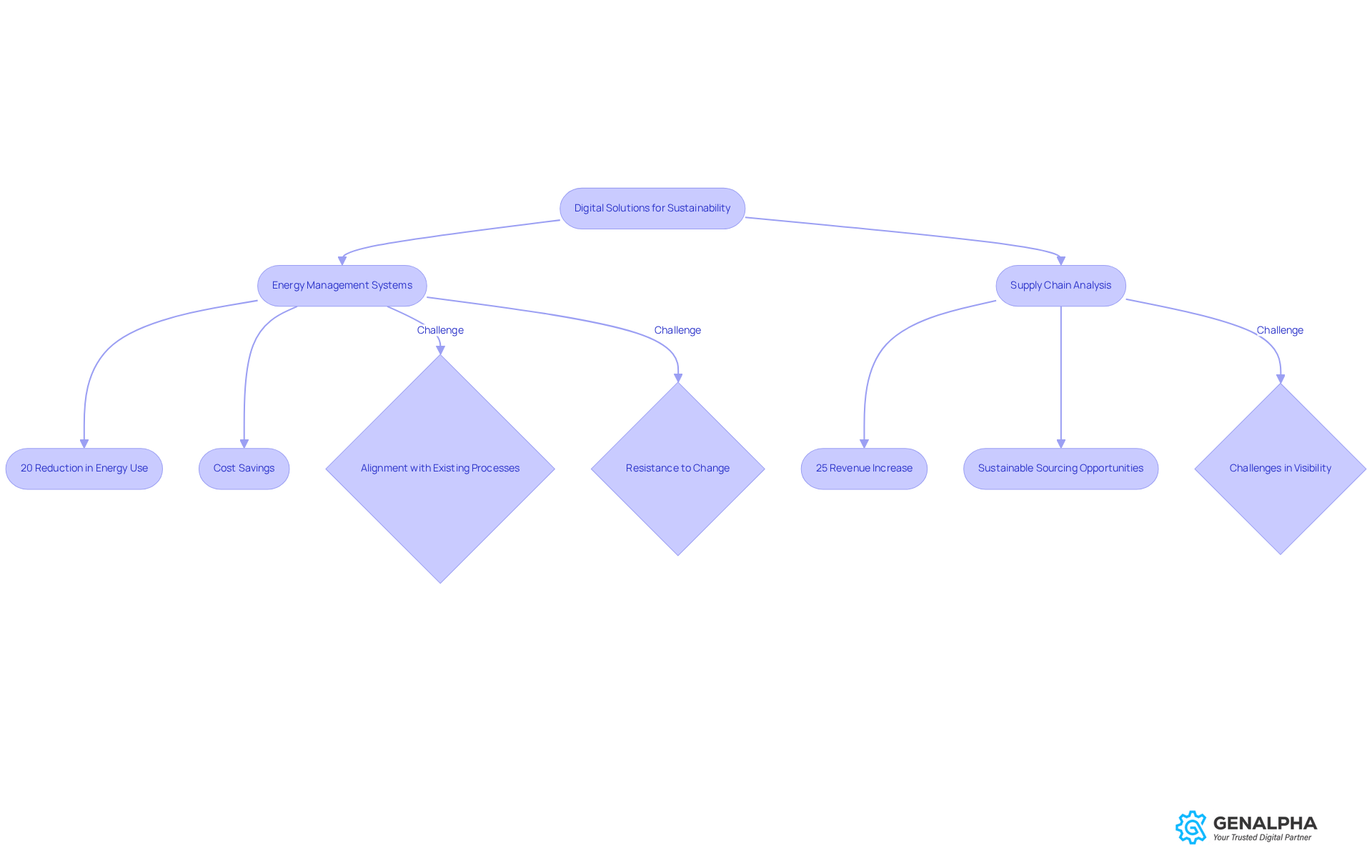

Digital solutions are really shaking things up in sustainable manufacturing! By optimizing how we use resources and cutting down on waste, they play a crucial role in making our processes greener. Take energy management systems, for example. They help monitor and reduce energy consumption, which can lead to some serious cost savings and boost operational efficiency. With real-time monitoring and automated tweaks, these systems can slash energy use by up to 20%. This not only helps producers stick to the rules but also meets the growing demand from consumers for eco-friendly practices. Plus, recent research shows that digital technologies could help lower global carbon emissions by as much as 20% by 2050. That’s a big deal for our sustainability goals!

But that’s not all—supply chain analysis is another game-changer. It helps manufacturers spot sustainable sourcing opportunities, allowing them to make smarter choices that lessen their environmental impact. Companies that use advanced analytics have seen a 25% bump in revenue tied to their sustainability efforts. A great example of this is Arbor's platform, which cuts down the time and costs of manual life cycle assessments, boosting revenue even further.

By embracing these tech advancements, producers can really contribute to a circular economy where we focus on resource efficiency and waste reduction. That said, we can’t ignore the hurdles manufacturers face when rolling out these solutions. Aligning with existing processes and overcoming resistance to change can be tough. Tackling these challenges is key to unlocking all the benefits that digital transformation can bring to sustainable manufacturing. So, what do you think? Are you ready to dive into this journey of innovation?

Artificial Intelligence and Machine Learning: Drive Innovation in Manufacturing

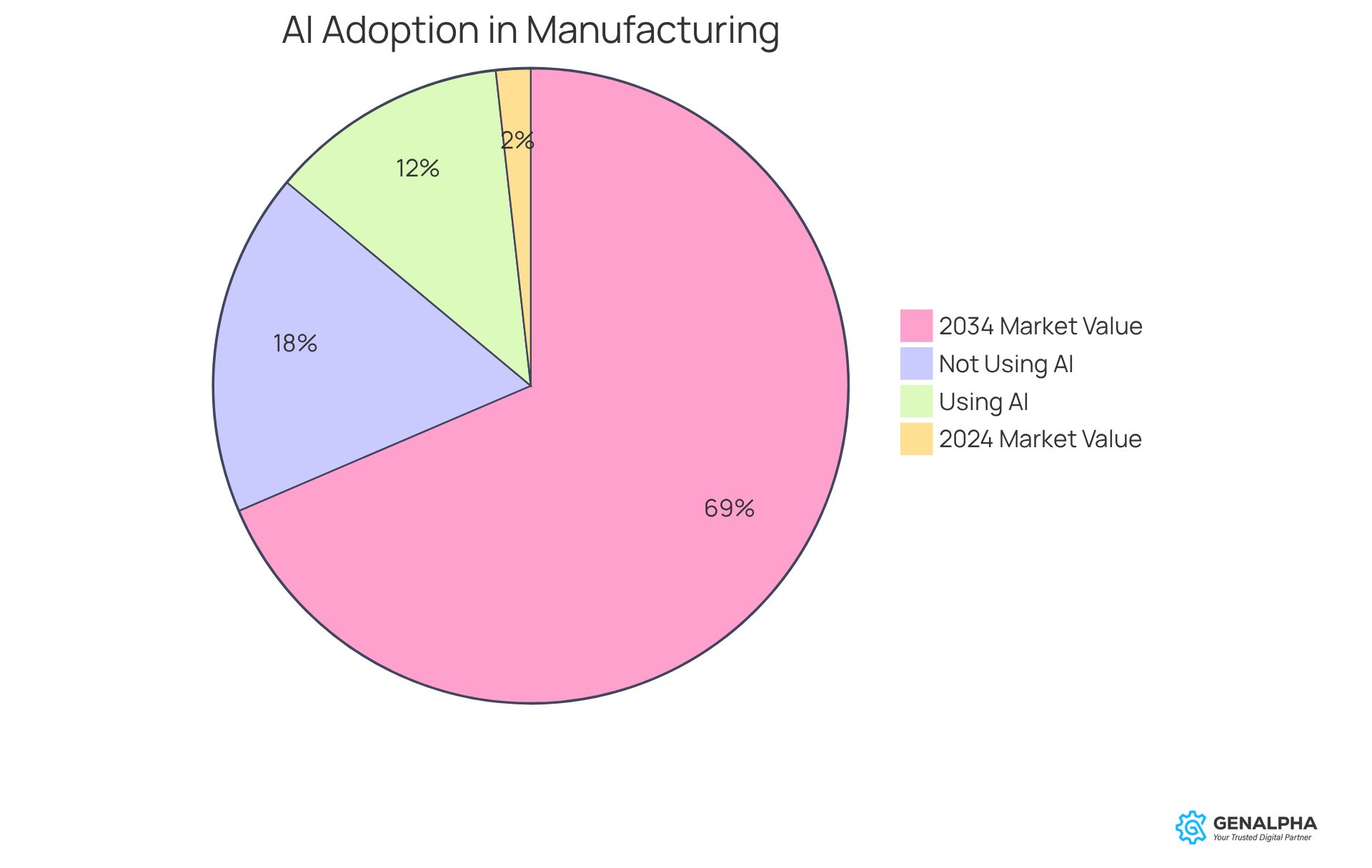

Artificial intelligence (AI) and machine learning (ML) are really shaking things up in the manufacturing world! By harnessing predictive analytics, these technologies are driving innovation and boosting efficiency. Imagine being able to anticipate market demands—producers can now adjust their production schedules proactively. Did you know that 41% of producers are already using AI to manage supply chain information? This is a game changer for operational responsiveness and efficiency.

Predictive analysis doesn’t just streamline quality control; it also optimizes production workflows. With AI-driven predictive maintenance, producers can cut down on unexpected downtime by up to 30% and reduce maintenance costs by 25%. This proactive approach minimizes disruptions and encourages a culture of continuous improvement.

Real-world applications of predictive analysis in manufacturing are already showing fantastic results. For instance, 90% of leading machine producers are investing in predictive data technology to foresee equipment failures, which helps improve maintenance schedules and operational reliability. Plus, the global AI in manufacturing market is set to explode, growing from USD 5.94 billion in 2024 to around USD 230.95 billion by 2034. This growth reflects how the industry is recognizing AI's potential to boost productivity and competitiveness.

As Sreedhar Sistu, Vice President of AI Offers at Schneider Electric, puts it, "We see AI as a key strategic enabler for our effectiveness, to do things better, faster, and more economically, while delivering essential products to our customers." This blend of AI and ML through predictive analysis is not just driving the digital transformation of manufacturing; it’s fostering innovation and helping producers meet market needs with agility and precision.

So, how can you leverage these technologies in your operations? The future is bright with AI and ML leading the way!

Predictive Maintenance: Reduce Downtime with Advanced Analytics

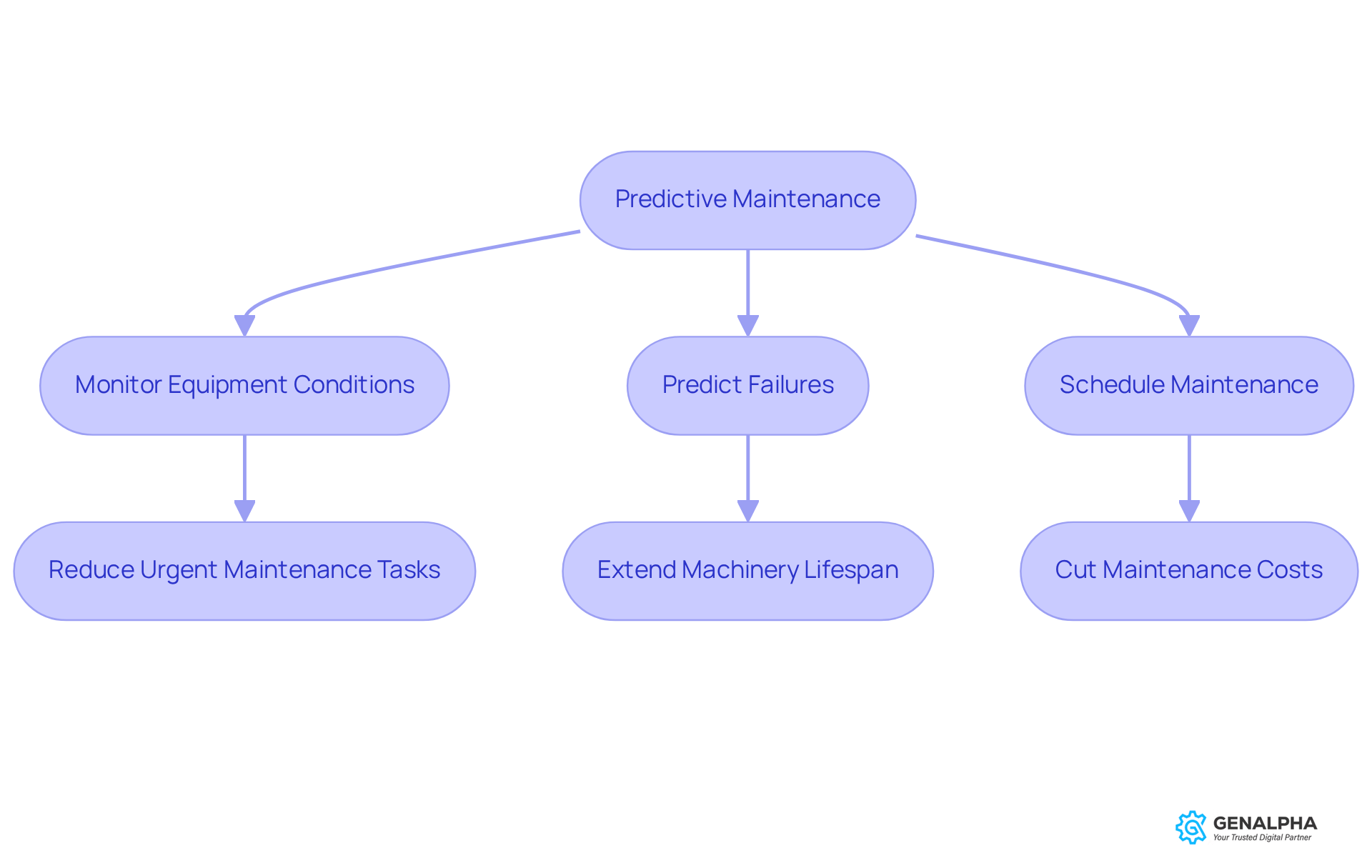

Have you ever considered how the digital transformation of manufacturing through predictive maintenance can change the game for manufacturers? It’s all about using smart analysis to keep an eye on equipment conditions and predict failures before they strike. This proactive approach is part of the digital transformation of manufacturing, allowing companies to schedule maintenance in advance, which can drastically cut down on unexpected downtime.

For instance, a global chemical plant that implemented predictive maintenance on 33 pieces of equipment saw urgent maintenance tasks drop to just 43% of their total activities. That’s a clear win for data-driven decision-making in the digital transformation of manufacturing when it comes to boosting operational efficiency!

But that’s not all—predictive maintenance can also help extend the lifespan of machinery. By leveraging real-time data and insights, manufacturers can support the digital transformation of manufacturing by fine-tuning their maintenance schedules and servicing equipment only when it’s truly necessary. This way, they avoid unnecessary wear and tear on their machines.

For example, consider a significant case study from a global automotive facility that illustrates the digital transformation of manufacturing. By embracing the digital transformation of manufacturing, they achieved a whopping 30% reduction in maintenance costs and a 40% boost in equipment uptime by pairing predictive analytics with digital twin technology. The financial impact is huge! Research indicates that the digital transformation of manufacturing can significantly reduce unplanned machine downtime by as much as 50% through the adoption of predictive maintenance. With the average annual cost of downtime per facility estimated at $129 million, it’s clear that effective maintenance strategies are crucial for the digital transformation of manufacturing.

As Luke Hamer puts it, 'Implementing predictive maintenance helps organizations reduce unplanned machine downtime by up to 50%.' This really highlights how advanced analytics can drive the digital transformation of manufacturing by transforming equipment maintenance, ensuring smoother production flows and improved operational efficiency. So, why not consider how predictive maintenance could benefit your operations?

Digital Twin Technology: Optimize Operations with Virtual Asset Replicas

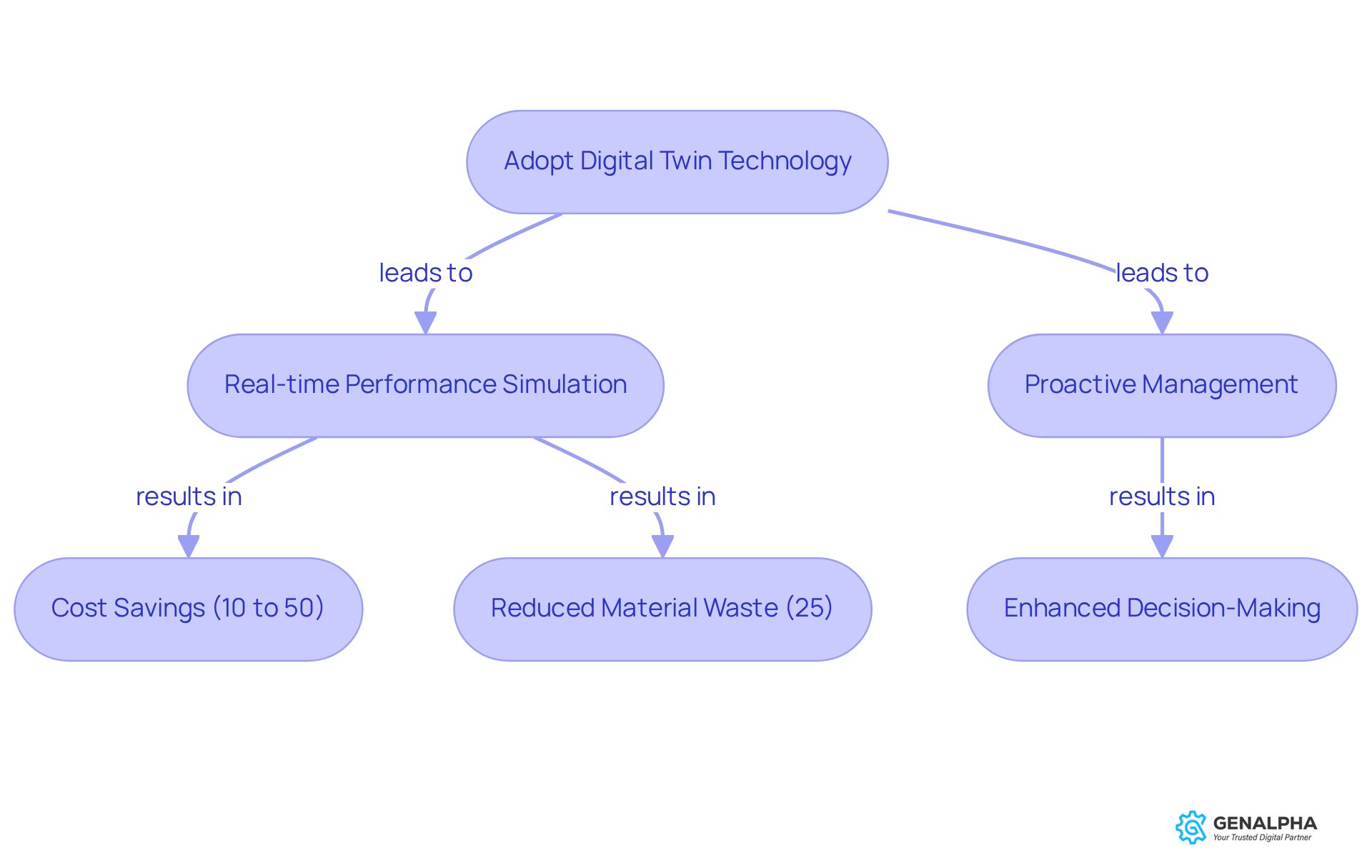

Have you ever wondered how the digital transformation of manufacturing can impact the industry through technology? Digital twin technology is doing just that by creating virtual replicas of physical assets. This innovation allows manufacturers to simulate and analyze performance in real-time, leading to better planning, testing, and optimization of processes. Imagine the increase in efficiency and the reduction in expenses! For instance, a major German manufacturer adopted a virtual replica of their warehouse, which greatly enhanced visibility and communication. The result? A fantastic 10% savings and a 25% decrease in material waste.

But that’s not all! Virtual twins enable organizations to move from reactive to proactive management. With real-time data at their fingertips, manufacturers can quickly spot issues, slashing maintenance costs and boosting asset uptime. Take SKF, for example. They created a virtual twin of their entire distribution network, optimizing operations and improving lead times significantly.

The impact of virtual twins on operational efficiency is truly remarkable. Companies using this technology can experience efficiency gains ranging from 10% to 50%. Siemens even notes that "efficiency gains can reach 10-50%!" These virtual asset replicas not only enhance decision-making but also support continuous improvement initiatives. Ultimately, they drive profitability and customer satisfaction. So, if you're looking to modernize operations and gain a competitive edge, the digital transformation of manufacturing by integrating digital twins into your processes is essential. What are you waiting for?

Conclusion

The digital transformation of manufacturing is a game-changer, reshaping the entire industry landscape. It’s not just a nice-to-have anymore; it’s essential for equipment makers who want to boost operational efficiency, cut costs, and stay competitive. This transformation streamlines processes and nurtures a culture of continuous improvement, helping manufacturers adapt quickly to what the market demands.

Throughout this article, we’ve explored some key benefits of digital transformation. Think about:

- Enhanced efficiency through automation

- Cost savings from predictive analytics

- Improved safety with IoT technologies

- Smart use of data analytics for better decision-making

Plus, the integration of AI, machine learning, and digital twin technology is paving the way for innovation and operational excellence, leading to happier customers and more sustainable manufacturing practices.

As the manufacturing sector keeps evolving, the message is clear: it’s time to embrace the digital transformation journey. By investing in cutting-edge digital solutions and fostering a culture of innovation, manufacturers can place themselves at the forefront of the industry, ready to face challenges and grab opportunities. The future of manufacturing is digital, and those who adapt will not just survive—they’ll thrive in this dynamic environment.

Frequently Asked Questions

What is GenAlpha Technologies and what do they offer?

GenAlpha Technologies provides advanced digital solutions tailored for producers and suppliers, including their flagship product, Equip360, which enhances operational efficiency.

How does Equip360 improve operational efficiency?

Equip360 optimizes inventory management and boosts online sales capabilities, merging seamlessly with existing ERP systems to enhance productivity and forecasting precision.

What are the potential benefits of using Equip360?

Producers can see a 10% to 30% rise in throughput, a 15% to 30% improvement in labor productivity, and a 10 percentage point increase in OTIF scores. Additionally, forecasting precision can improve by up to 85%.

What challenges do producers face in implementing digital solutions like Equip360?

Producers often encounter high implementation costs and concerns about data protection, which can hinder technological transformation initiatives.

How does digital transformation affect manufacturing processes?

Digital transformation automates repetitive tasks and streamlines workflows, leading to increased operational efficiency, reduced production times, and minimized errors.

What role do IoT devices play in manufacturing?

IoT devices monitor machine performance in real-time, enabling predictive maintenance that prevents costly downtimes and ensures consistent product quality.

What are some statistics regarding employee satisfaction with automation?

88% of employees report feeling more satisfied and less stressed due to automation, with positivity in finance increasing from 66% to 89% after automation was introduced.

What are the challenges associated with implementing automation in manufacturing?

Challenges include integration issues, process complexity, employee resistance, and a lack of training.

How can manufacturers optimize costs using digital tools?

Digital tools help identify inefficiencies, reduce waste, and improve demand forecasting accuracy, leading to better inventory management and lower operational costs.

What savings can manufacturers expect from implementing predictive analytics and automation?

Companies can report a 15-20% drop in operational costs within the first year, and those blending predictive insights with automation can achieve 30-40% greater efficiency in expenses.

Why is training important in the context of digital transformation?

Investing in training and data literacy empowers teams to effectively leverage predictive analytics, significantly boosting efficiency and profitability in a competitive landscape.