Overview

Have you ever wondered how B2B ERP integration can revolutionize the way equipment manufacturers operate? Well, let’s dive into ten key benefits that highlight just that! First off, it streamlines operations, making everything run smoother. Imagine having data that’s not only accurate but also readily available—this is a game changer for enhancing customer experiences.

For example, many manufacturers have reported increased operational efficiency and significant cost savings. Plus, with the ability to adapt to market changes, ERP systems are proving to be essential for transforming manufacturing processes. This isn't just about keeping up; it's about fostering real business growth.

So, what do you think? Could your operations benefit from a little ERP magic? Let’s explore these benefits together and see how they can make a difference in your business!

Introduction

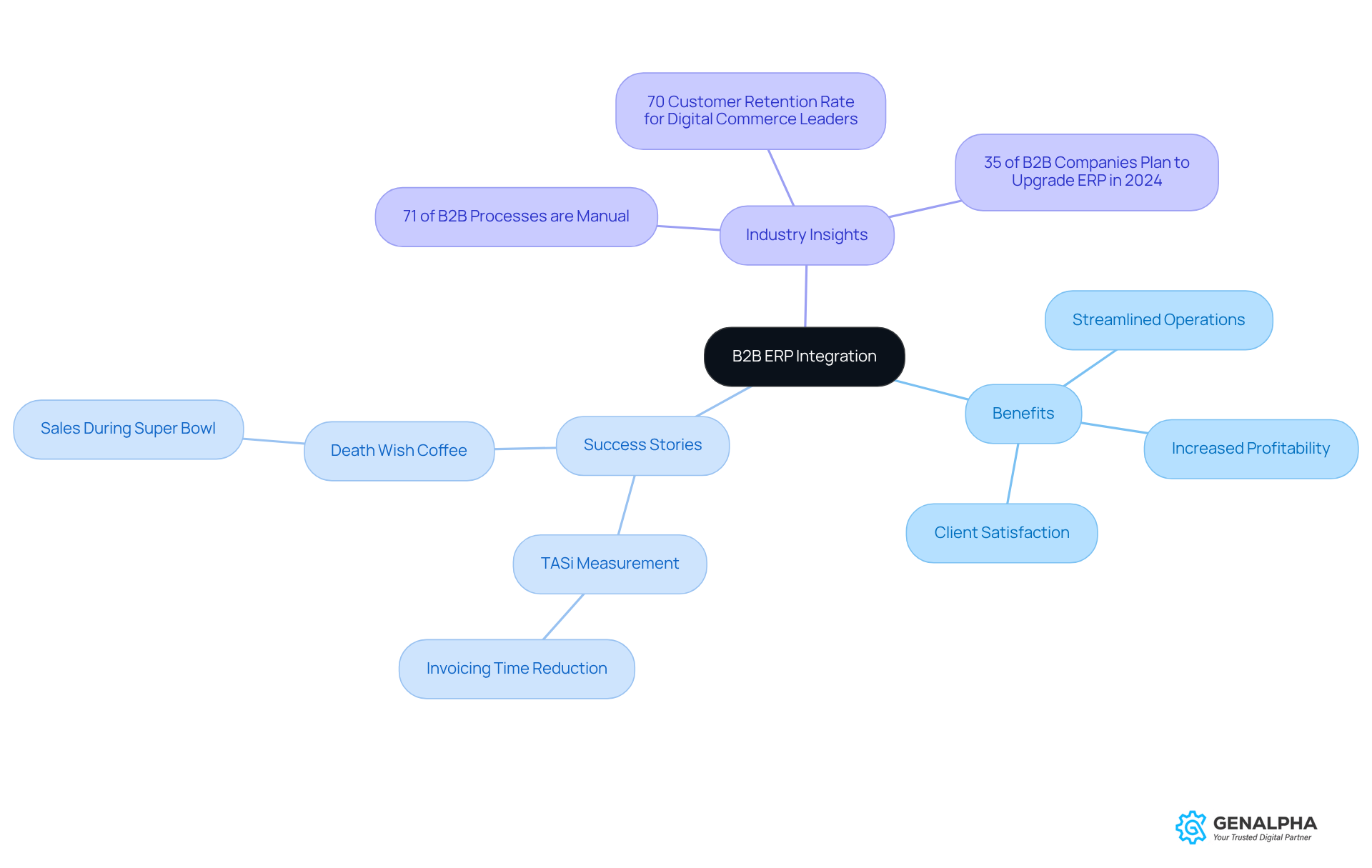

The manufacturing landscape is changing fast, and equipment manufacturers are increasingly looking to B2B ERP integration as a key strategy for success. This integration not only streamlines operations but also boosts data accuracy and enhances customer experiences, ultimately driving profitability. But here's the kicker: with 71% of B2B executives still relying on manual processes, it raises an important question: how can manufacturers harness ERP systems to tackle operational challenges and remain competitive in such a fast-paced market?

Exploring the many benefits of B2B ERP integration reveals a world of transformative potential just waiting to be unlocked. So, let’s dive in and see how these systems can make a real difference for manufacturers like you!

GenAlpha Technologies: Streamline Operations with B2B ERP Integration

At GenAlpha Technologies, we’re all about crafting digital solutions that really make a difference for producers and distributors. Imagine streamlining your operations and cutting down on those tedious manual tasks—sounds great, right? By utilizing b2b erp integration, we help businesses boost data accuracy along the way.

Take our flagship product, Equip360, for instance. It’s a fantastic example of how effective ERP integration can transform inventory management and supercharge your digital sales performance. Not only does this lead to better profitability, but it also enhances client satisfaction. Producers enjoy smoother workflows and can respond to market demands more effectively.

We’ve seen some amazing success stories from various manufacturers. Equip360 has truly changed the game, allowing for operational efficiencies through real-time data access and automation. Just look at TASi Measurement, which slashed its invoicing time from 22 days down to just two days with Epicor Kinetic. That’s a real win!

Industry leaders are on the same page, stressing that b2b erp integration is essential for staying competitive in today’s fast-paced market. In fact, 71% of B2B executives describe their processes as 'moderately to extremely manual.' This really highlights the importance of adopting advanced ERP solutions, particularly b2b erp integration, to fuel growth and operational excellence. And get this—front runners in digital commerce have reported a remarkable 70% customer retention rate, further proving the positive impact of b2b erp integration. So, are you ready to join the ranks of those transforming their operations?

Enhanced Data Accuracy: Ensure Quality Control in Manufacturing Processes

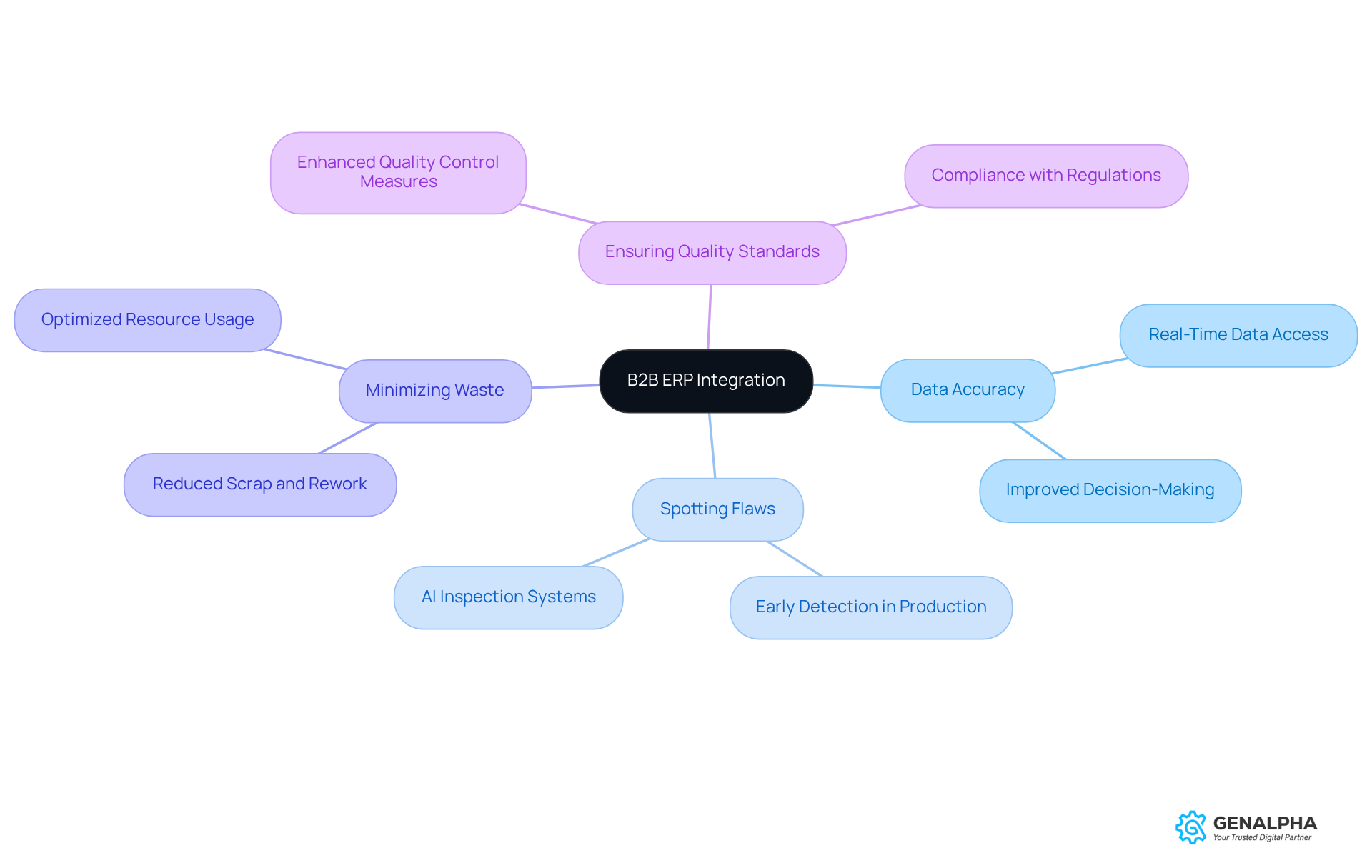

Have you ever thought about how b2b erp integration can truly transform businesses? By centralizing information across various departments, these systems significantly boost data accuracy. Imagine all stakeholders having access to real-time, consistent data—it's a game changer for quality control!

When producers have precise information at their fingertips, they can spot flaws early in the production process. This not only minimizes waste but also ensures that products meet quality standards. And who doesn’t want that?

By leveraging b2b erp integration, producers can implement robust quality control measures that enhance overall operational efficiency. So, why not consider how these systems could benefit your operations? It might just be the boost you need!

Real-Time Visibility: Optimize Decision-Making and Responsiveness

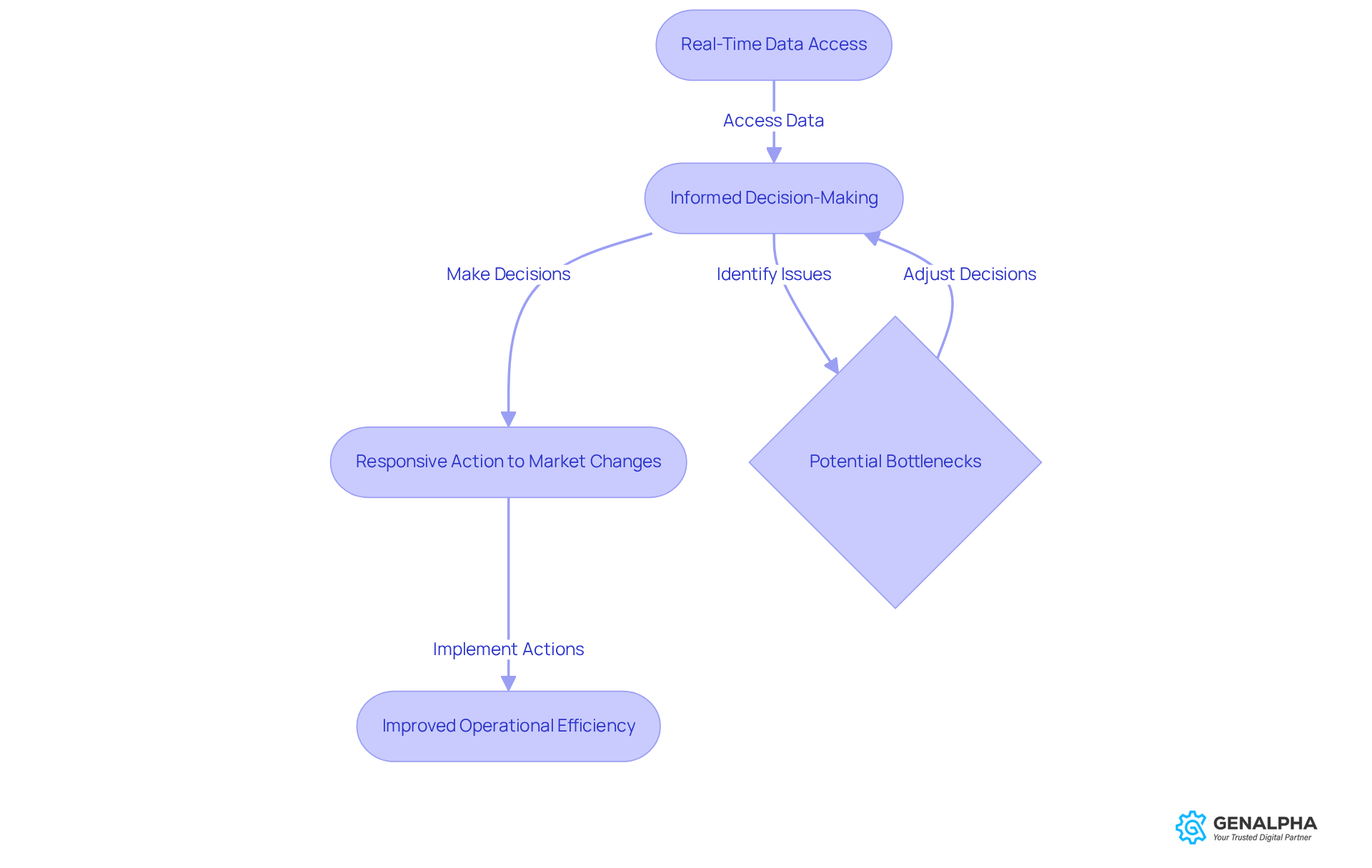

Have you ever wondered how real-time visibility can transform manufacturing operations? One of the biggest perks of B2B ERP integration is just that! This capability allows decision-makers to keep a close eye on production processes, inventory levels, and supply chain dynamics. Imagine having quick access to real-time information—producers can make informed choices on the fly, boosting their ability to respond to client needs and market changes.

In today’s fast-paced manufacturing world, agility is everything. Delays can mean lost sales and unhappy clients, and nobody wants that. Experts in supply chain management agree: leveraging real-time data not only streamlines operations but also encourages a proactive approach to decision-making. For instance, producers using ERP solutions can spot potential bottlenecks early on, allowing for quick adjustments that improve workflows and resource allocation.

Ultimately, the B2B ERP integration of real-time data into decision-making processes leads to better operational efficiency and a stronger competitive edge in the marketplace. So, how are you planning to harness this advantage in your operations?

Streamlined Business Processes: Increase Efficiency and Reduce Bottlenecks

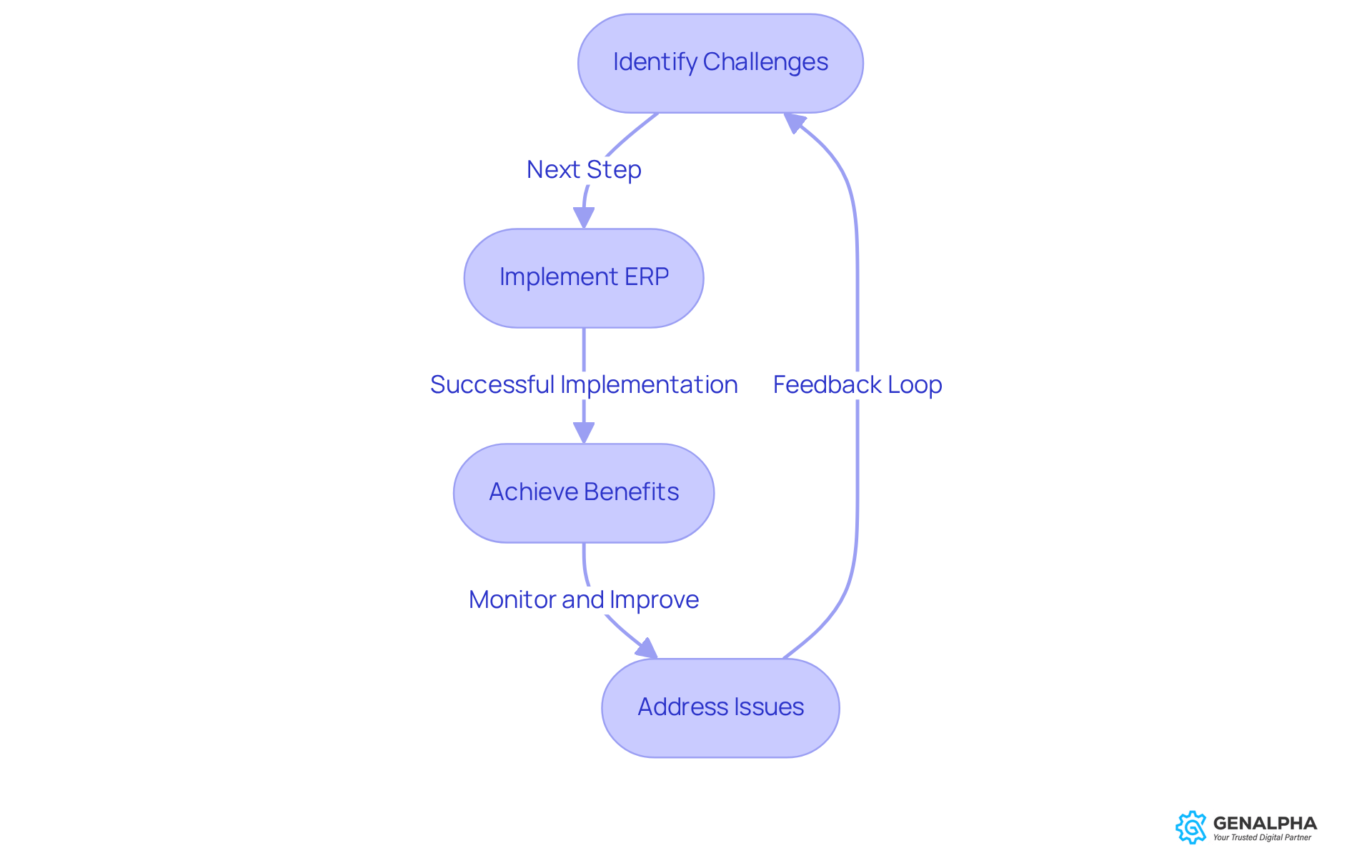

Have you ever thought about how b2b erp integration can truly change the game for businesses? It’s all about streamlining processes by automating those repetitive tasks we all dread, while also boosting communication between departments. This nifty automation helps eliminate those frustrating bottlenecks that come from manual data entry and miscommunication, paving the way for a smooth flow of information.

As a result, manufacturers can ramp up productivity and cut down on lead times, which means they can get products to customers faster. For example, take a healthcare company that decided to implement an ERP solution; they saw a 7% bump in operational efficiency and a 4% increase in revenue after making the switch! This kind of agility allows organizations to quickly adapt to changing market demands, keeping them competitive.

Productivity specialists often say that 'ERP is a transformation engine—not merely an automation tool.' This highlights how b2b erp integration and enhancing transparency can lead to smarter decision-making and more agile service delivery. However, let’s not forget that implementing ERP isn’t always smooth sailing. Challenges like employee resistance and the need for effective training and communication can pop up, so it’s crucial to address these issues to ensure a successful transition.

So, are you ready to explore how ERP can transform your business? Let’s dive in!

Improved Customer Experience: Foster Stronger Relationships with Clients

Incorporating ERP solutions gives producers a holistic view of client interactions, which really boosts the client experience. This broader perspective allows for personalized service, ensuring that inquiries are answered promptly and orders are processed efficiently. By leveraging accurate data and streamlined workflows, manufacturers can meet client expectations more effectively, fostering stronger relationships and enhancing client loyalty.

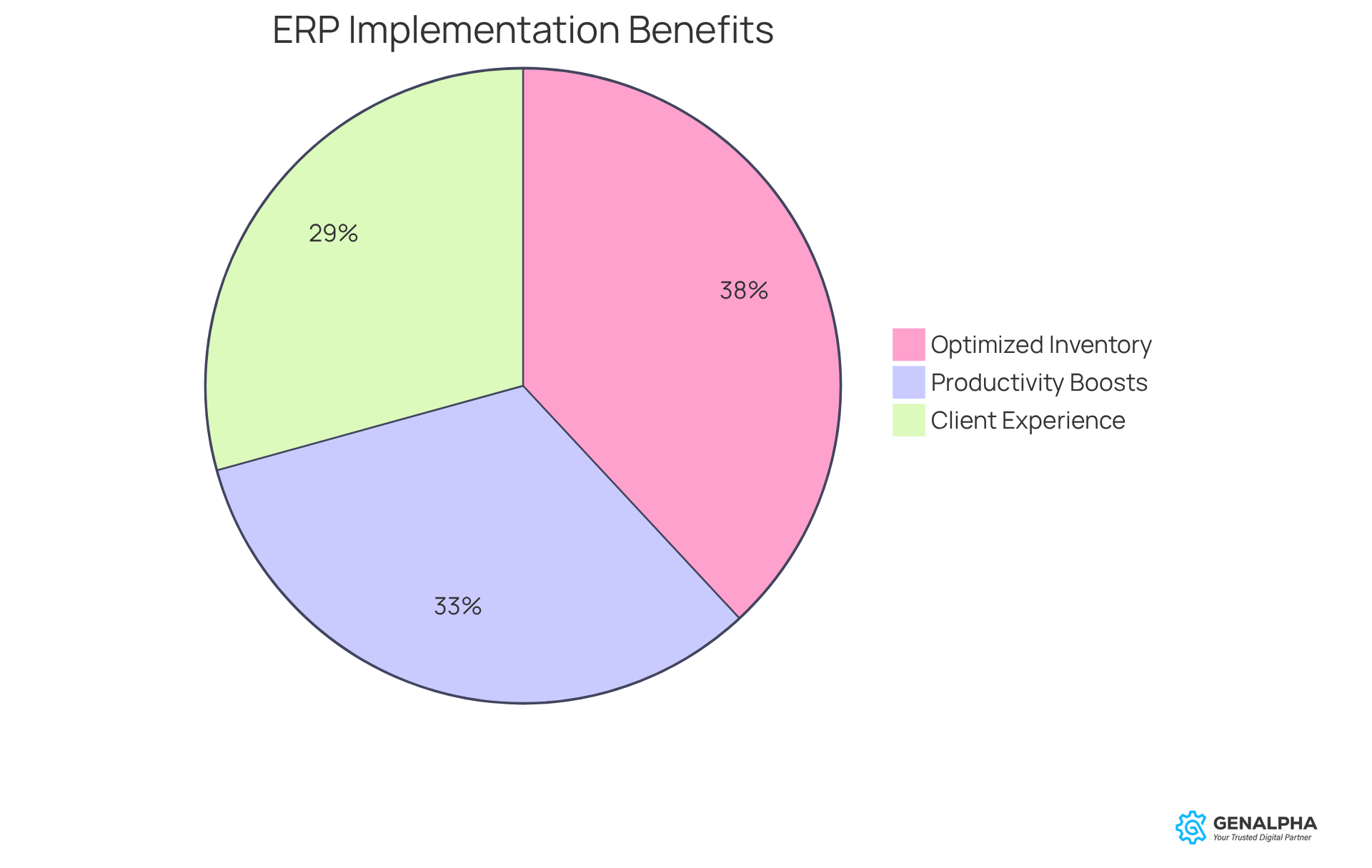

Did you know that research shows 70% of businesses improved their client experience after implementing ERP systems? Various studies highlight the operational benefits of these systems. A great client experience not only drives repeat business but also encourages referrals, helping to expand the client base. For instance, 91% of organizations reported optimized inventory levels after ERP implementation. This directly enhances service delivery and client satisfaction by making sure products are available when needed.

As CRM expert Shep Hyken puts it, 'Customer loyalty is earned, not given. Keep earning it every day.' This really emphasizes how crucial it is for manufacturers to continuously improve their service quality through effective b2b erp integration. Plus, 78% of businesses noticed productivity boosts after implementing ERP systems, showcasing the operational benefits that can lead to better client relationships.

By breaking down data silos—something 77% of organizations achieved—and enhancing service quality—80% of respondents reported an average increase in perceived service quality of 25% after b2b erp integration—manufacturers can create a more personalized and responsive customer experience. So, how about taking a closer look at how ERP can transform your client interactions?

Enhanced Inventory Management: Optimize Supply Chain Operations

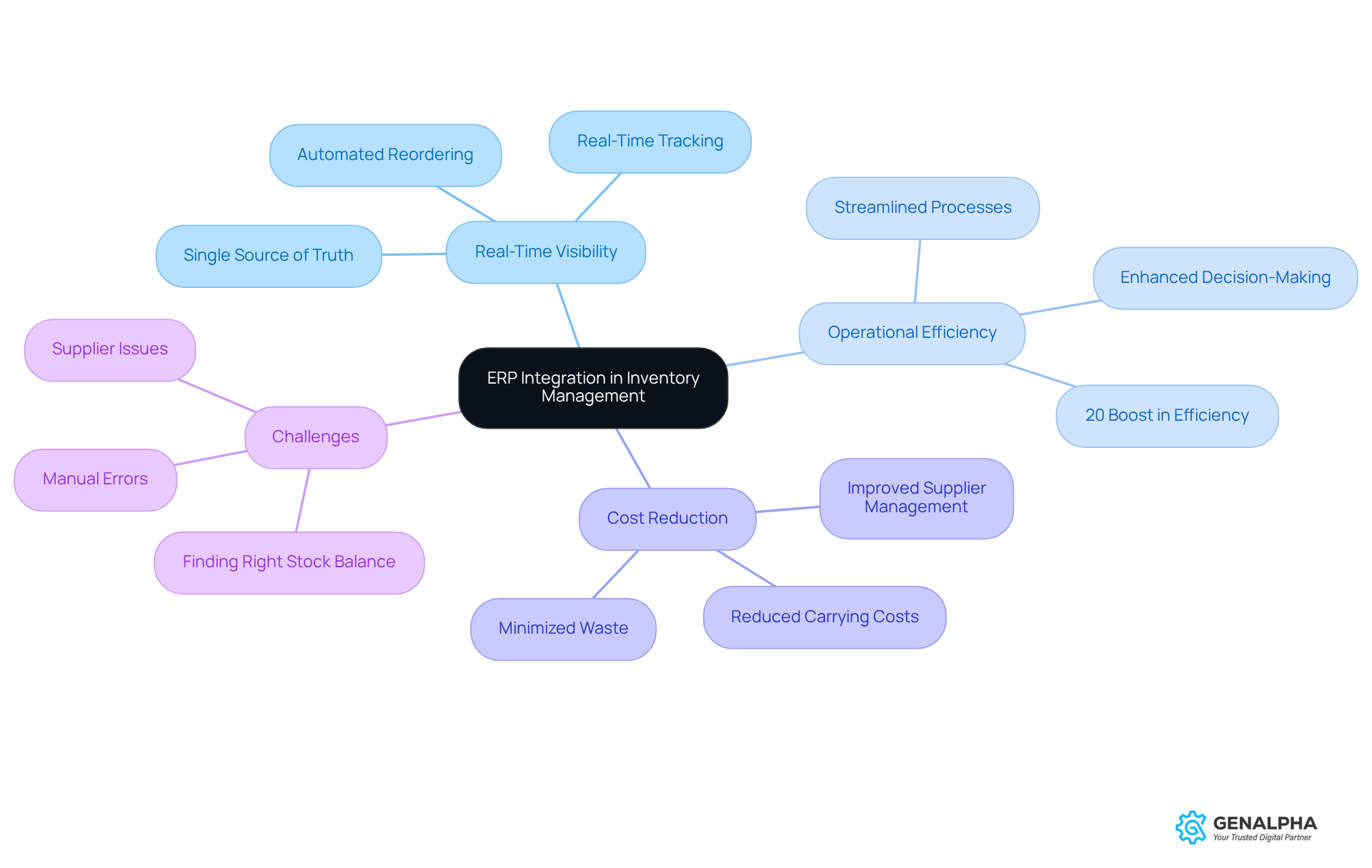

ERP integration is a game changer for inventory management! It gives you real-time visibility into stock levels, demand forecasts, and supply chain dynamics. This means producers can optimize their inventory, cutting down on excess stock while also minimizing the risk of running out. For instance, take a look at the case study 'Transforming Inventory Management with ERP Solutions.' Companies that jumped on the ERP bandwagon saw a whopping 20% boost in operational efficiency, all thanks to better inventory precision and smoother processes.

By keeping a close eye on inventory, manufacturers can ensure that the right products are available right when they're needed. This not only slashes carrying costs but also boosts customer satisfaction with timely deliveries. As one supply chain expert put it, 'An effective ERP system isn’t just about functionality; it’s about making informed decisions backed by reliable data.' Plus, the CEO of Apparel Co. shared, 'Switching to automated inventory processes revolutionized our operations. Not only did we save time, but we also increased our accuracy and customer satisfaction.'

This B2B ERP integration promotes a proactive approach to inventory management, enabling producers to quickly respond to market demands and supply chain changes, ultimately improving their operational efficiency. But let's not forget, businesses often face hurdles in inventory management, like finding the right stock balance and handling supplier issues. Thankfully, ERP solutions are here to help tackle these challenges with features like automated reordering and real-time tracking, making it easier for producers to navigate the complexities of inventory management effectively.

Cost Savings: Reduce Operational Expenses through Integration

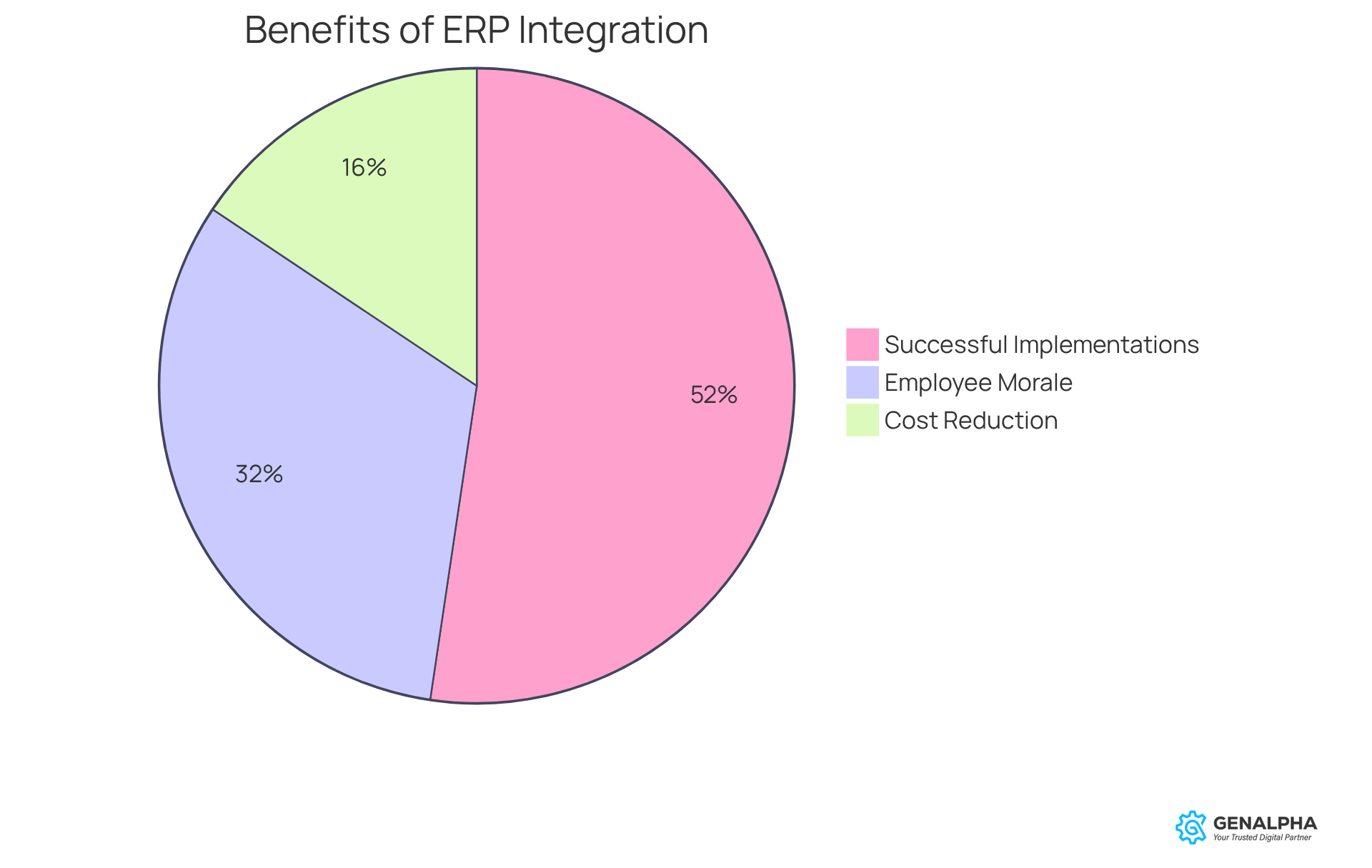

B2B ERP integration can lead to some serious cost savings when integrating ERP systems! By implementing B2B ERP integration, producers can automate processes, reduce manual errors, and optimize resource allocation to streamline their operations. This means lower operational costs related to labor, inventory management, and production inefficiencies. In fact, organizations that have implemented B2B ERP integration report reductions in operational expenses of up to 20%. Plus, 67% of producers describe their implementations as 'successful' or 'very successful.' It’s clear that these frameworks can offer significant financial advantages!

But that’s not all—ERP solutions also bring clarity to financial planning and budgeting. This helps producers make informed decisions that can lead to even more cost reductions. Take Galaxy Insulations and Dry Lining Ltd, for example. They achieved industry-leading inventory levels through optimized stock control using Intact iQ. This really shows how effective B2B ERP integration can lead to operational efficiencies.

Moreover, the automation features of ERP solutions in the realm of B2B ERP integration don’t just streamline workflows; they also boost employee productivity and satisfaction. In fact, 41% of companies report an increase in employee morale after implementing ERP systems, which in turn contributes to lower operational expenses. This dual benefit of cost savings and enhanced workforce engagement allows producers to reinvest those savings into growth and innovation, giving them a competitive edge in the market.

So, how can producers start incorporating ERP solutions? It’s all about evaluating existing processes and identifying areas where automation can help reduce inefficiencies. Working with ERP consultants can provide tailored insights and ensure a smoother transition. Why not take that first step today?

Scalability: Adapt to Market Changes and Business Growth

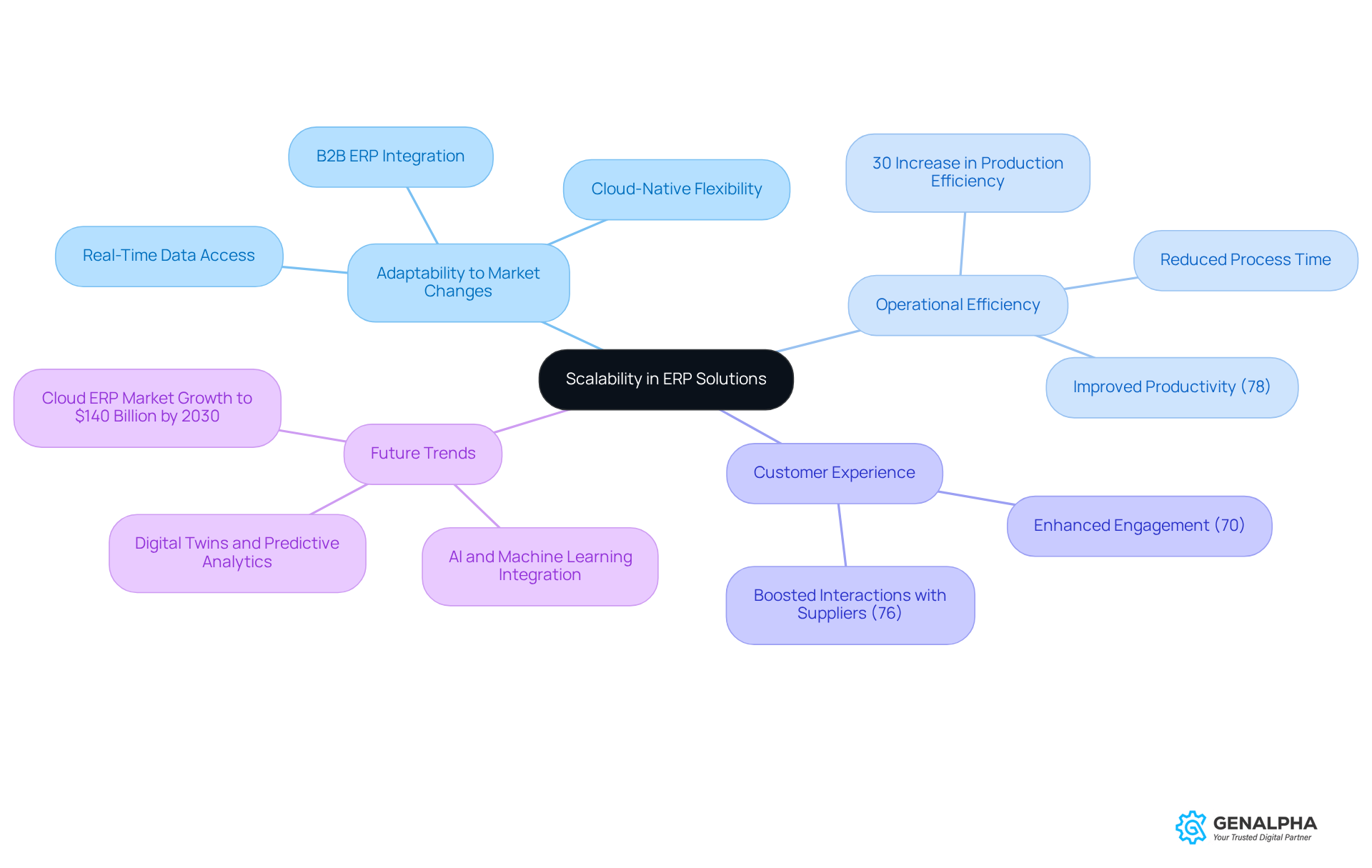

ERP solutions are designed for scalability, making it easy for producers to adapt to market changes and evolving business needs. As companies grow, their operational requirements shift, and B2B ERP integration can help manage these changes without major disruptions. This adaptability is vital for keeping operations running smoothly, especially when demand fluctuates or business models evolve.

By investing in scalable ERP solutions, producers can boost their operational capabilities and set themselves up for long-term success in a competitive landscape. For instance, a mid-sized automotive parts producer in Michigan saw a 30% increase in production efficiency within just six months of adopting a cloud-based ERP solution. This example highlights how effective B2B ERP integration can result in significant performance improvements.

Additionally, industry leaders are emphasizing that the future of ERP will feature enhanced autonomy through AI and machine learning. This means producers will be able to respond proactively to market dynamics. Did you know that 70% of organizations have reported a better customer experience as a direct benefit of their ERP projects? This underscores the essential role these systems play in enhancing customer engagement.

As we look ahead, the cloud ERP market is expected to grow significantly, reaching $140 billion by 2030. For producers, focusing on scalable solutions will be key to thriving in an ever-changing environment. So, are you ready to explore how ERP can transform your operations?

Automation: Increase Productivity and Reduce Manual Errors

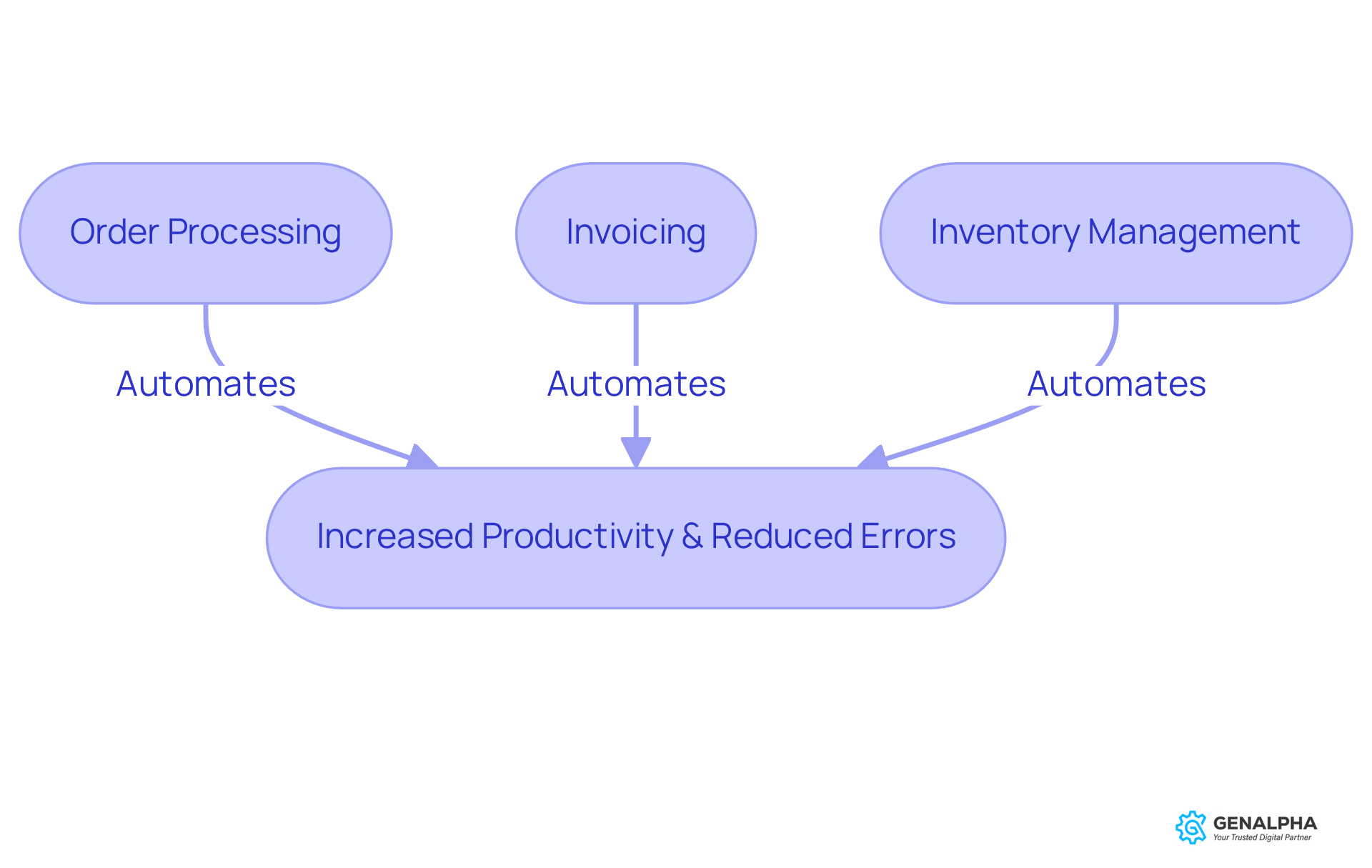

Have you ever felt bogged down by routine tasks at work? One of the biggest perks of B2B ERP integration is how it automates those everyday chores, boosting productivity and cutting down on manual errors. By automating things like:

- Order processing

- Invoicing

- Inventory management

Manufacturers can really free up their employees’ time. This allows them to dive into more strategic initiatives that matter. Not only does B2B ERP integration ramp up operational efficiency, but it also improves accuracy—automated processes are way less prone to mistakes than manual data entry. So, what does that mean for your team? A more productive workforce and a smoother operational flow!

Compliance and Security: Safeguard Data and Build Trust

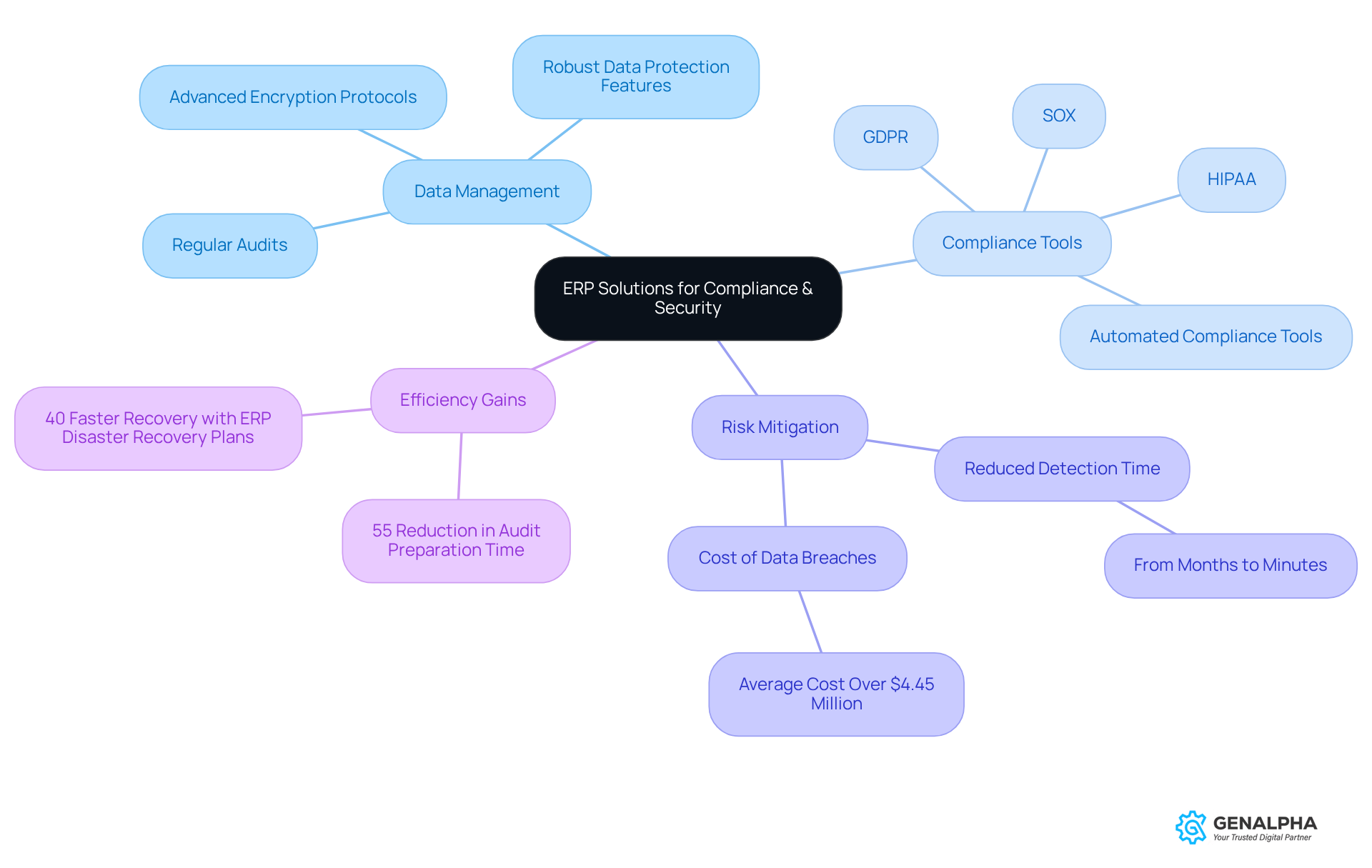

Have you ever thought about how incorporating ERP solutions can really amp up compliance and security? It’s true! These solutions come packed with robust data management and protection features. Imagine having built-in compliance tools that help manufacturers stick to industry regulations like SOX, GDPR, and HIPAA. Plus, they use advanced encryption protocols and role-based access controls to keep sensitive data safe. And don’t forget about regular audits that ensure compliance and data integrity.

Now, here’s something eye-opening: companies that use ERP-level monitoring can cut down the time it takes to detect security threats from months to mere minutes. In today’s fast-paced digital world, that’s a game-changer! This proactive approach not only helps mitigate risks associated with data breaches—where the average cost has skyrocketed to over $4.45 million—but also highlights why investing in ERP security measures is crucial.

Take the Target data breach as a reminder of vulnerabilities within ERP frameworks. It really shows how essential strong security measures are. By prioritizing data protection through b2b erp integration, manufacturers can not only maintain a positive reputation but also foster customer loyalty and achieve business growth.

As Ray Wang points out, relying on a single cloud provider for ERP solutions can ensure comprehensive security, reinforcing the value of integrated systems. And here’s a fun fact: automated compliance tools can slash audit preparation time by 55%! That’s a clear win showcasing the efficiency gains from b2b erp integration. So, what are you waiting for? Let’s prioritize ERP security together!

Conclusion

B2B ERP integration is a game changer for equipment manufacturers looking to boost their operational efficiency and stay competitive. By adopting this technology, businesses can streamline processes, enhance data accuracy, and build stronger customer relationships, all of which lead to increased profitability and growth.

Throughout this article, we’ve explored several key benefits of B2B ERP integration. For instance, enhanced data accuracy ensures quality control, while real-time visibility optimizes decision-making. Each of these advantages plays a vital role in creating a more agile and responsive manufacturing environment. Plus, integration helps streamline business processes, elevates customer experiences, improves inventory management, drives significant cost savings, and provides the scalability needed to adapt to market changes. These insights really highlight the transformative power of ERP solutions in the manufacturing sector.

In an industry that’s constantly evolving, embracing advanced ERP systems is more important than ever. As manufacturers strive to outpace the competition, leveraging B2B ERP integration isn’t just a choice—it’s essential. Investing in these solutions not only enhances operational efficiencies but also positions organizations for sustainable growth and innovation. So, why wait? Now is the time to embrace the power of ERP integration and unlock the full potential of your manufacturing operations!

Frequently Asked Questions

What is B2B ERP integration and why is it important?

B2B ERP integration is the process of connecting business operations and data across various departments through an Enterprise Resource Planning system. It is important because it boosts data accuracy, streamlines operations, and enhances competitiveness in today’s fast-paced market.

How does GenAlpha Technologies help businesses with B2B ERP integration?

GenAlpha Technologies provides digital solutions, such as their flagship product Equip360, which helps businesses streamline operations, reduce manual tasks, and improve data accuracy. This integration transforms inventory management and enhances digital sales performance.

What benefits have manufacturers experienced from using Equip360?

Manufacturers using Equip360 have reported operational efficiencies through real-time data access and automation. For example, TASi Measurement reduced its invoicing time from 22 days to just two days, showcasing significant improvements in efficiency.

What role does data accuracy play in quality control?

Data accuracy is crucial for quality control as it allows producers to have real-time, consistent information. This enables them to identify flaws early in the production process, minimize waste, and ensure that products meet quality standards.

How does real-time visibility impact decision-making in manufacturing?

Real-time visibility allows decision-makers to monitor production processes, inventory levels, and supply chain dynamics closely. This access to real-time information enhances the ability to make informed decisions quickly, improving responsiveness to client needs and market changes.

What are the advantages of leveraging real-time data in operations?

Leveraging real-time data streamlines operations, encourages proactive decision-making, and helps identify potential bottlenecks early. This leads to improved workflows, better resource allocation, and ultimately, enhanced operational efficiency and competitiveness.

How does B2B ERP integration contribute to customer retention?

B2B ERP integration contributes to customer retention by improving operational efficiencies and enhancing client satisfaction. Companies that effectively utilize these systems have reported a 70% customer retention rate, indicating a strong positive impact on customer loyalty.